- Joined

- Aug 31, 2011

- Messages

- 2,986

Does anybody know how this stuff files and sands?

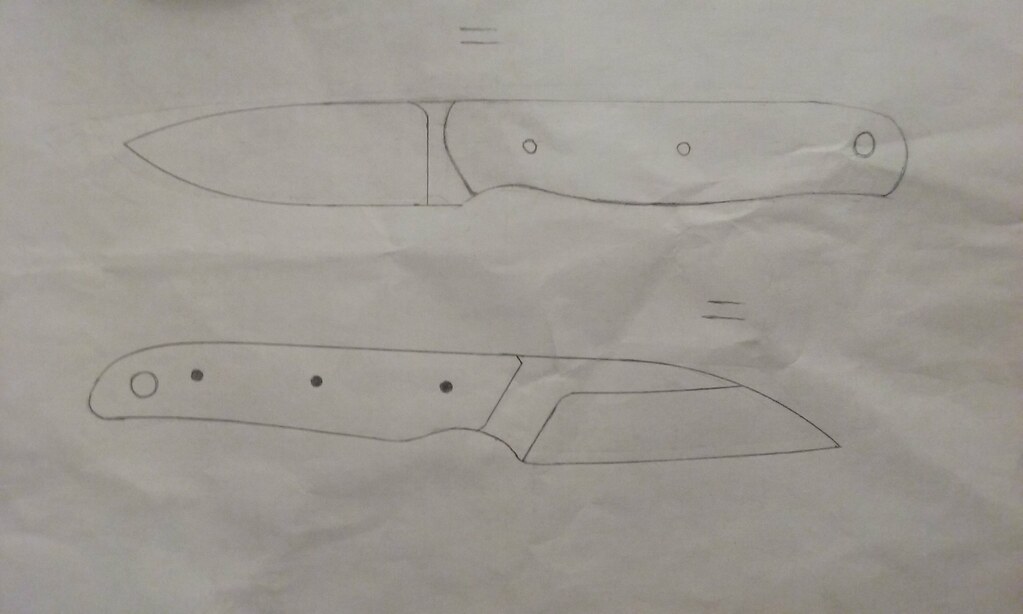

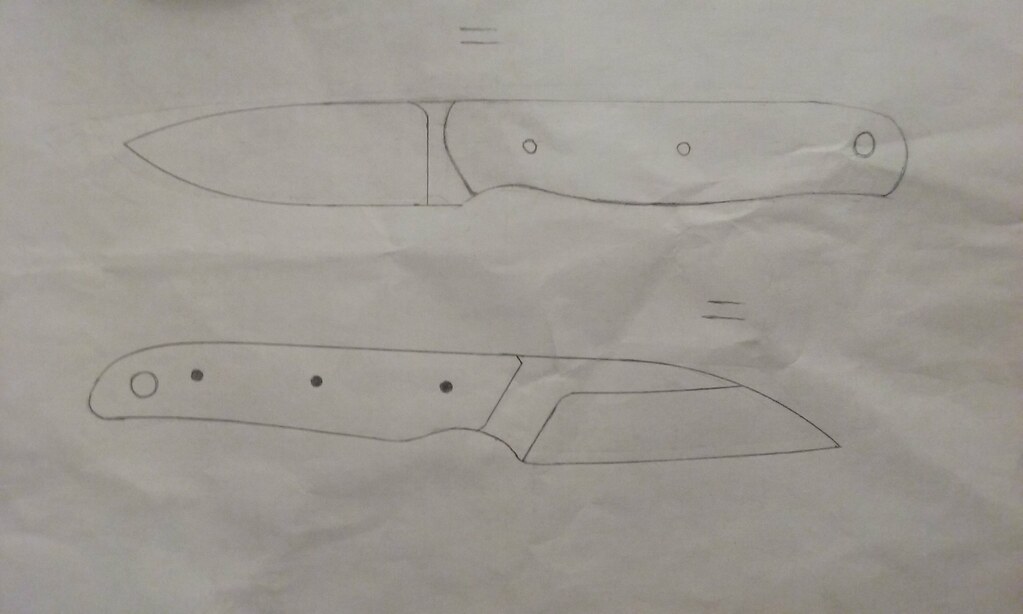

I think it is promising as a steel for utility and EDC blades. Here are the patterns I have in mind.

Wharncliffe is 3 1/8", backpacker is 3 1/4"

I like to go minimalist, and the wharncliffe would be easy to carry, and versatile at OAL 7 1/2".

Backpacker is OAL 7 5/8".

I think it is promising as a steel for utility and EDC blades. Here are the patterns I have in mind.

Wharncliffe is 3 1/8", backpacker is 3 1/4"

I like to go minimalist, and the wharncliffe would be easy to carry, and versatile at OAL 7 1/2".

Backpacker is OAL 7 5/8".

Last edited: