You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The cleaver discussion thread.....

- Thread starter TwinStick

- Start date

- Joined

- Jul 16, 2016

- Messages

- 1,922

Uh oh, either it's The Purge or somebody got caught with some panties in the glove box that weren't his wife's!

- Joined

- Apr 23, 2017

- Messages

- 67

Agent H, you are the man! I'm working only on my phone, and am unable to find the .jpeg links... I will need to get to a pc when I need a pic up! Thanks! Yes fellas, that's my old lady and no, it's not the purge... but that's kinda what we were going for lol! There is just something about a "creepy" masked, hot chick holding a large weapon... you can't go wrong!

- Joined

- Apr 12, 2006

- Messages

- 2,506

A couple of new big blades that got shipped out earlier this month. Two firsts on these: the cord-wrapped one is the heaviest I've made, and the slab handle on the lamb splitter is the longest slab I've ever made.

Both of them are forged from 80CrV2 steel with Boltaron sheaths.

The wrapped one has an 18" blade and weighs 5.14 pounds, the first of mine to weigh more than 5 pounds. The handle is 22" long, scorched hemp on top of a neoprene foundation, with West System marine epoxy.

carcasssplitter10 by James Helm, on Flickr

carcasssplitter10 by James Helm, on Flickr

carcasssplitter12 by James Helm, on Flickr

carcasssplitter12 by James Helm, on Flickr

carcasssplitter14 by James Helm, on Flickr

carcasssplitter14 by James Helm, on Flickr

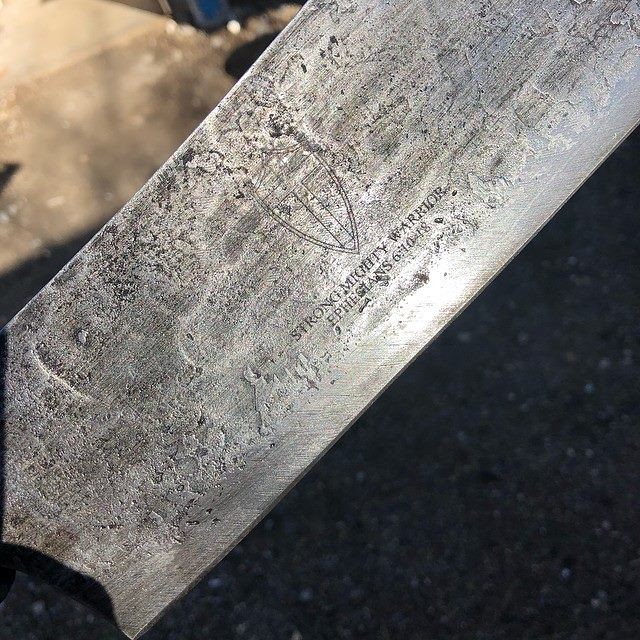

It was a Christmas gift from a wife to her husband, and she had me laser engrave this on the blade.

carcasssplitter13 by James Helm, on Flickr

carcasssplitter13 by James Helm, on Flickr

carcassssplitter11 by James Helm, on Flickr

carcassssplitter11 by James Helm, on Flickr

The lamb splitter is an over-sized version of what is usually a large one-handed butcher knife-looking blade. The blade is 17 1/4", the handle is 17", and the weight is 4.125 pounds. It has the longest slab handle I've ever made, from tan TeroTuf with flared stainless steel tube rivets.

The customer has assured me that the lamb splitter will be used for butchering.

lambsplitter03 by James Helm, on Flickr

lambsplitter03 by James Helm, on Flickr

lambsplitter04 by James Helm, on Flickr

lambsplitter04 by James Helm, on Flickr

lambsplitter05 by James Helm, on Flickr

lambsplitter05 by James Helm, on Flickr

More details in the video:

Both of them are forged from 80CrV2 steel with Boltaron sheaths.

The wrapped one has an 18" blade and weighs 5.14 pounds, the first of mine to weigh more than 5 pounds. The handle is 22" long, scorched hemp on top of a neoprene foundation, with West System marine epoxy.

carcasssplitter10 by James Helm, on Flickr

carcasssplitter10 by James Helm, on Flickr carcasssplitter12 by James Helm, on Flickr

carcasssplitter12 by James Helm, on Flickr carcasssplitter14 by James Helm, on Flickr

carcasssplitter14 by James Helm, on FlickrIt was a Christmas gift from a wife to her husband, and she had me laser engrave this on the blade.

carcasssplitter13 by James Helm, on Flickr

carcasssplitter13 by James Helm, on Flickr carcassssplitter11 by James Helm, on Flickr

carcassssplitter11 by James Helm, on FlickrThe lamb splitter is an over-sized version of what is usually a large one-handed butcher knife-looking blade. The blade is 17 1/4", the handle is 17", and the weight is 4.125 pounds. It has the longest slab handle I've ever made, from tan TeroTuf with flared stainless steel tube rivets.

The customer has assured me that the lamb splitter will be used for butchering.

lambsplitter03 by James Helm, on Flickr

lambsplitter03 by James Helm, on Flickr lambsplitter04 by James Helm, on Flickr

lambsplitter04 by James Helm, on Flickr lambsplitter05 by James Helm, on Flickr

lambsplitter05 by James Helm, on FlickrMore details in the video:

Last edited:

- Joined

- Apr 23, 2017

- Messages

- 67

Both are absolutely AMAZING! What does it cost to commission one of the carcass splitters? I have nothing to go on other than a new model, manufactured version is around $350. I imagine these run a lil higher than that, lol! I would buy one of these over those any day though. Practical art at it's finest, great work.

- Joined

- Apr 12, 2006

- Messages

- 2,506

Both are absolutely AMAZING! What does it cost to commission one of the carcass splitters? I have nothing to go on other than a new model, manufactured version is around $350. I imagine these run a lil higher than that, lol! I would buy one of these over those any day though. Practical art at it's finest, great work.

Thank you! I'll send you a PM.

- Joined

- Feb 1, 2012

- Messages

- 13,727

A couple of new big blades that got shipped out earlier this month. Two firsts on these: the cord-wrapped one is the heaviest I've made, and the slab handle on the lamb splitter is the longest slab I've ever made.

Both of them are forged from 80CrV2 steel with Boltaron sheaths.

The wrapped one has an 18" blade and weighs 5.14 pounds, the first of mine to weigh more than 5 pounds. The handle is 22" long, scorched hemp on top of a neoprene foundation, with West System marine epoxy.

carcasssplitter10 by James Helm, on Flickr

carcasssplitter12 by James Helm, on Flickr

carcasssplitter14 by James Helm, on Flickr

It was a Christmas gift from a wife to her husband, and she had me laser engrave this on the blade.

carcasssplitter13 by James Helm, on Flickr

carcassssplitter11 by James Helm, on Flickr

The lamb splitter is an over-sized version of what is usually a large one-handed butcher knife-looking blade. The blade is 17 1/4", the handle is 17", and the weight is 4.125 pounds. It has the longest slab handle I've ever made, from tan TeroTuf with flared stainless steel tube rivets.

The customer has assured me that the lamb splitter will be used for butchering.

lambsplitter03 by James Helm, on Flickr

lambsplitter04 by James Helm, on Flickr

lambsplitter05 by James Helm, on Flickr

More details in the video:

Don't you wish they'd have asked you to make one of those on Forged in Fire?

- Joined

- Apr 12, 2006

- Messages

- 2,506

Howdy, folks. Been a busy, productive year, and not as much time has been spent on forums as I used to. But I have had a couple of interesting projects I wanted to share. They are the two largest carcass splitters I've made so far, one completed in February and one in August.

The first was a commission from a chef who owns multiple restaurants who wanted as large a carcass splitter as I could make as a gift for a friend of his. The second was a commission from a fellow who butchers a lot of hogs. Both started out as bars of 5/16" x 4" 80CrV2 steel, and both ended up with hemp cord over neoprene handle wraps and Boltaron sheaths. And both were hair-shaving sharp when shipped.

The first one was forged as close to shape as possible with my power hammer, with only minimal cleanup grinding along the edge profile before grinding and filing the bevel to final dimensions. It ended up with a blade just under 20" long, 5 3/4" wide at the widest, 41 1/4" overall length, and a weight of 8.22 pounds, a good 3 pounds more than my previous largest carcass splitter.

csp03 by James Helm, on Flickr

csp03 by James Helm, on Flickr

csp04 by James Helm, on Flickr

csp04 by James Helm, on Flickr

In comparison with a "small" carcass splitter that is more like a 15" blade, 15" tang, and around 4 lb weight, and with a 6' 2" Sasquatch for scale.

csp01 by James Helm, on Flickr

csp01 by James Helm, on Flickr

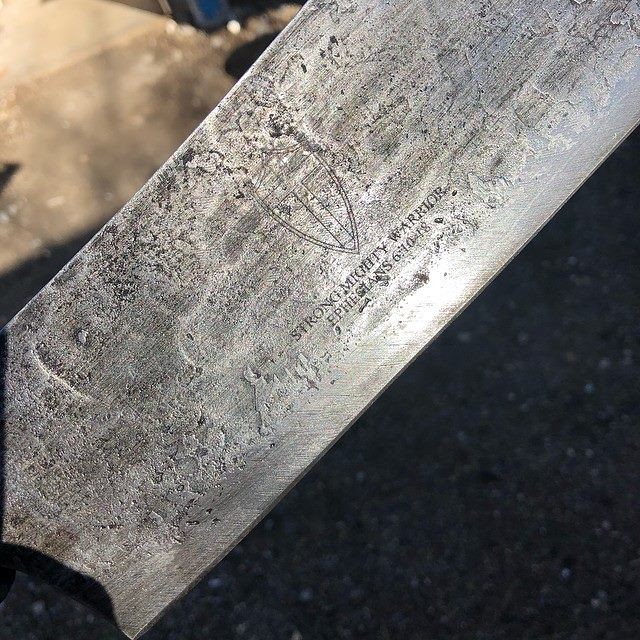

The second one was forged as close to final dimensions as I could on my power hammer, but the end was trimmed and the spine had minimal cleanup grinding. It isn't quite as wide, but is larger in all other ways at just over 20" blade length, 5 1/2" wide, and 44" overall lenth, with a weight just over 9 pounds.

cs01 by James Helm, on Flickr

cs01 by James Helm, on Flickr

cs02 by James Helm, on Flickr

cs02 by James Helm, on Flickr

It picked up some extra texture from sitting a few days in a mixture of vinegar that had more 30% acidity in it than I realized (most of the mixture was 9% or 5%). Usually the vinegar eats the scale off without affecting the steel; this time it definitely added texture.

cs03 by James Helm, on Flickr

cs03 by James Helm, on Flickr

In comparison with a 15" bladed bush sword that weighed just under 1.33 lbs prior to stock removal:

cs11 by James Helm, on Flickr

cs11 by James Helm, on Flickr

Sasquatch for scale.

cs06 by James Helm, on Flickr

cs06 by James Helm, on Flickr

Gotta say, it does nothing to help you hitch hike, even if you show a little leg! I had just finished demonstrating how it could shave hair, too!

cs04 by James Helm, on Flickr

cs04 by James Helm, on Flickr

More details, process video and pics, and general silliness in this video:

The first was a commission from a chef who owns multiple restaurants who wanted as large a carcass splitter as I could make as a gift for a friend of his. The second was a commission from a fellow who butchers a lot of hogs. Both started out as bars of 5/16" x 4" 80CrV2 steel, and both ended up with hemp cord over neoprene handle wraps and Boltaron sheaths. And both were hair-shaving sharp when shipped.

The first one was forged as close to shape as possible with my power hammer, with only minimal cleanup grinding along the edge profile before grinding and filing the bevel to final dimensions. It ended up with a blade just under 20" long, 5 3/4" wide at the widest, 41 1/4" overall length, and a weight of 8.22 pounds, a good 3 pounds more than my previous largest carcass splitter.

csp03 by James Helm, on Flickr

csp03 by James Helm, on Flickr csp04 by James Helm, on Flickr

csp04 by James Helm, on FlickrIn comparison with a "small" carcass splitter that is more like a 15" blade, 15" tang, and around 4 lb weight, and with a 6' 2" Sasquatch for scale.

csp01 by James Helm, on Flickr

csp01 by James Helm, on FlickrThe second one was forged as close to final dimensions as I could on my power hammer, but the end was trimmed and the spine had minimal cleanup grinding. It isn't quite as wide, but is larger in all other ways at just over 20" blade length, 5 1/2" wide, and 44" overall lenth, with a weight just over 9 pounds.

cs01 by James Helm, on Flickr

cs01 by James Helm, on Flickr cs02 by James Helm, on Flickr

cs02 by James Helm, on FlickrIt picked up some extra texture from sitting a few days in a mixture of vinegar that had more 30% acidity in it than I realized (most of the mixture was 9% or 5%). Usually the vinegar eats the scale off without affecting the steel; this time it definitely added texture.

cs03 by James Helm, on Flickr

cs03 by James Helm, on FlickrIn comparison with a 15" bladed bush sword that weighed just under 1.33 lbs prior to stock removal:

cs11 by James Helm, on Flickr

cs11 by James Helm, on FlickrSasquatch for scale.

cs06 by James Helm, on Flickr

cs06 by James Helm, on FlickrGotta say, it does nothing to help you hitch hike, even if you show a little leg! I had just finished demonstrating how it could shave hair, too!

cs04 by James Helm, on Flickr

cs04 by James Helm, on FlickrMore details, process video and pics, and general silliness in this video:

- Joined

- Mar 27, 2010

- Messages

- 4,981

- Joined

- Feb 25, 2014

- Messages

- 1,486

Gotta say, it does nothing to help you hitch hike, even if you show a little leg!

Yeaaahhhh.... Not even Agent_H's lady from post #260 in this thread would be getting a lift with that thing over her shoulder, even though there would be many who would like to see that particular pairing. Nice work, and if I ever need to storm Mordor I am totally visiting your forge first.

- Joined

- Mar 31, 2018

- Messages

- 1,874

I can't recall whether or not I've shared this anywhere on the forum. I think I have but not in this thread.

It's an Underhill hog splitter. Made in Boston in 1841. I love how easy it is to see it's construction. It's 32" long and weighs 13lbs.

In Thomas Lamond's book on northern New England makers, he has an example of a very similar stamp from Underhill from 1843. So I know they were stamping them thus.

According to the same book, the only two Underhill's that were working in Boston at that time were Samuel Graham and Rufus K Underhill. Perhaps they worked together?

I believe it has been resteeled.

At 179 years old that makes sense!

One of my favorite parts is the folded steel in the grip. You can so easily see how they made it!

And lastly a few for scale;

Next to it is a full size 3-1/2lb raven hung on a 30" haft;

Wish it could talk.

It's an Underhill hog splitter. Made in Boston in 1841. I love how easy it is to see it's construction. It's 32" long and weighs 13lbs.

In Thomas Lamond's book on northern New England makers, he has an example of a very similar stamp from Underhill from 1843. So I know they were stamping them thus.

According to the same book, the only two Underhill's that were working in Boston at that time were Samuel Graham and Rufus K Underhill. Perhaps they worked together?

I believe it has been resteeled.

At 179 years old that makes sense!

One of my favorite parts is the folded steel in the grip. You can so easily see how they made it!

And lastly a few for scale;

Next to it is a full size 3-1/2lb raven hung on a 30" haft;

Wish it could talk.

Wow! That is an amazing piece! Talk about a well made tool, still seemingly unaffected by time. Even the stamp is still there. An impressive amount of steel. Very unique find! Thanks for sharing!I can't recall whether or not I've shared this anywhere on the forum. I think I have but not in this thread.

It's an Underhill hog splitter. Made in Boston in 1841. I love how easy it is to see it's construction. It's 32" long and weighs 13lbs.

In Thomas Lamond's book on northern New England makers, he has an example of a very similar stamp from Underhill from 1843. So I know they were stamping them thus.

View attachment 1403925

According to the same book, the only two Underhill's that were working in Boston at that time were Samuel Graham and Rufus K Underhill. Perhaps they worked together?

View attachment 1403927

I believe it has been resteeled.

At 179 years old that makes sense!

One of my favorite parts is the folded steel in the grip. You can so easily see how they made it!

And lastly a few for scale;

Next to it is a full size 3-1/2lb raven hung on a 30" haft;

Wish it could talk.