- Joined

- Sep 20, 2022

- Messages

- 6

Hello,

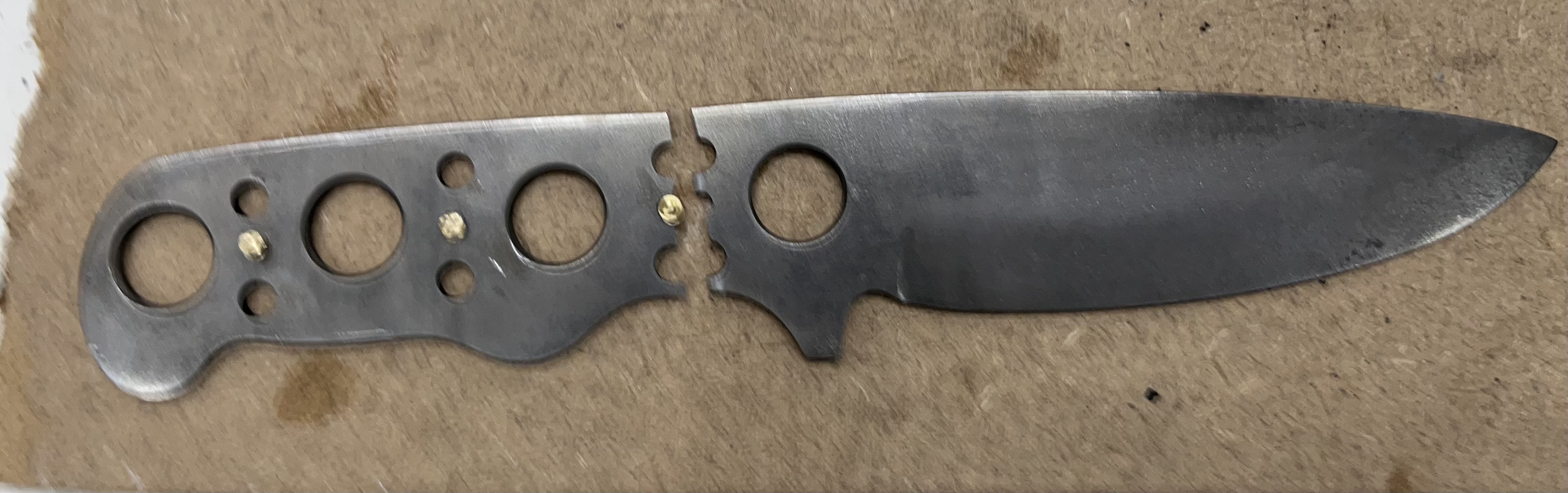

I've wanted to dive into knife making for a lot of years. I've been reading forums and watching YouTube for a couple years now and I'm finally in a place I can take a stab at making some. I finished my first knife, and it turned out OK, I think. Working on a skeleton knife now and I'd like to put some brass pins in the handle and I'm not sure if you do that before you heat treat or after. I've searched Google for a bit now and I can't find anything that says that's a good or bad idea to do before heat treating. Wondering if anyone had some thoughts on it.

Thank you,

Jeff

First knife:

I've wanted to dive into knife making for a lot of years. I've been reading forums and watching YouTube for a couple years now and I'm finally in a place I can take a stab at making some. I finished my first knife, and it turned out OK, I think. Working on a skeleton knife now and I'd like to put some brass pins in the handle and I'm not sure if you do that before you heat treat or after. I've searched Google for a bit now and I can't find anything that says that's a good or bad idea to do before heat treating. Wondering if anyone had some thoughts on it.

Thank you,

Jeff

First knife: