- Joined

- Oct 20, 2008

- Messages

- 5,547

This knife is a culmination of several ideas Ive had over the past two years- some of which Ive tried and failed at in that time. Im pleased that through that practice I learned enough to pull it off this time.

The blade has an 8 hollow grind and is slightly leaf shaped, at 11 long from point to bolster. Its forged from a 52100 bearing and hand sanded to 1500 grit. Overall length is 16.5 and width at quillions is 5.

The bolster is of course integral, and has been drilled and tapped through to accept the quillions. Its hand sanded to 600 grit.

The quillions are made of twist Damascus, also by me, and were lathe turned to shape and threaded on the ends. They were hot bent to final shape in place, so as to index correctly when tightened.

The handle is natural curly Koa wood from Maui. Its nice and chatoyant! The front of the handle is inlet to accept the bolster.

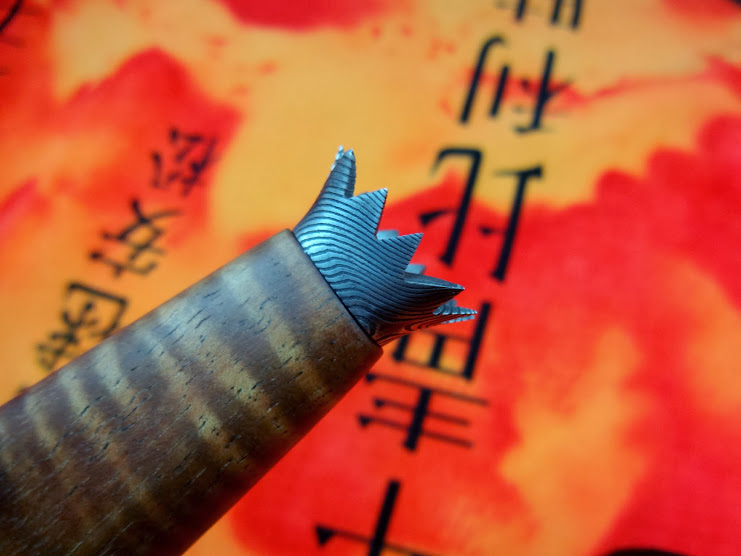

The finial is the same material as the quillions, and was carved and filed to shape.

The finial nut was turned from 300 series stainless, as is the take-down tool- the knife can be completely disassembled.

You may notice that this dagger does not feature a makers mark- there was no place on the piece where I thought it was appropriate. I'm working on a torch mark that will fit in small places on a piece like this.

Enough yakking, here's pics! Hope you all enjoy looking. Opinions solicited.

The blade has an 8 hollow grind and is slightly leaf shaped, at 11 long from point to bolster. Its forged from a 52100 bearing and hand sanded to 1500 grit. Overall length is 16.5 and width at quillions is 5.

The bolster is of course integral, and has been drilled and tapped through to accept the quillions. Its hand sanded to 600 grit.

The quillions are made of twist Damascus, also by me, and were lathe turned to shape and threaded on the ends. They were hot bent to final shape in place, so as to index correctly when tightened.

The handle is natural curly Koa wood from Maui. Its nice and chatoyant! The front of the handle is inlet to accept the bolster.

The finial is the same material as the quillions, and was carved and filed to shape.

The finial nut was turned from 300 series stainless, as is the take-down tool- the knife can be completely disassembled.

You may notice that this dagger does not feature a makers mark- there was no place on the piece where I thought it was appropriate. I'm working on a torch mark that will fit in small places on a piece like this.

Enough yakking, here's pics! Hope you all enjoy looking. Opinions solicited.