Willie71

Warren J. Krywko

- Joined

- Feb 23, 2013

- Messages

- 12,214

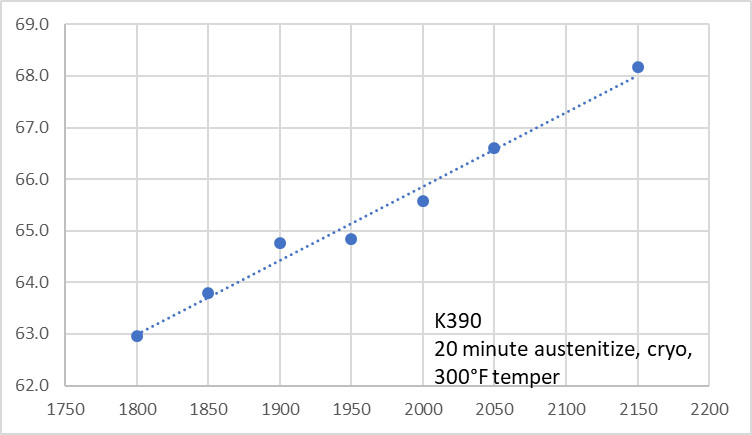

With the extra shop time, I have been able to catch up on a few projects I have had on the back burner. I was working with z-max and had a k-390 blank cut out, and 2100f was an appropriate austentizing temp for both, so I did a 25min soak, plate quench, cryo (overnight just because I didn’t have time to do tempers that evening), then four tempers at 400f, 2h each. The z-max came out at Rc70, which is about what I expected (Rc69 was the target), but the k390 came out at Rc69/70. It is only supposed to get to Rc66, so I was surprised.

I remember Larrin did some tests on A11 that required dropping aust temp to below 1900f to get mid 60’s rockwell numbers, so it seems K390 responds in similar ways. I’ll finish this one out, and see how it performs, but I suspect it will be brittle.

As a side note, red heat belts ground these two steels reasonable well, even at these hardnesses. I had to slow down to prevent glazing, but the single 36 grit belt has ground 2.5 high hardness high alloy super steel knives, and still has some life left in it. Pics coming soon.

I remember Larrin did some tests on A11 that required dropping aust temp to below 1900f to get mid 60’s rockwell numbers, so it seems K390 responds in similar ways. I’ll finish this one out, and see how it performs, but I suspect it will be brittle.

As a side note, red heat belts ground these two steels reasonable well, even at these hardnesses. I had to slow down to prevent glazing, but the single 36 grit belt has ground 2.5 high hardness high alloy super steel knives, and still has some life left in it. Pics coming soon.

8AB21AA1-DF4B-4BFD-A017-E415940524E4

8AB21AA1-DF4B-4BFD-A017-E415940524E4