When relief grinding (thinning out the metal above the edge) and sharpening my knives, I have tried to find a compromise between not going with too low a grit so I don't scratch the metal too deeply, and maybe cause other problems which I may not even be aware of, and not spending hours at it, which I have neither the time or interest to do.

These knives (excluding kitchen knives) are mostly fixed-blade and used for more demanding chores around the house and in the wilderness. I am not interested in smooth, polished, refined edges, but utility, toothy, V-edges (finished at around 400-600 grit) that are thin enough to cut well, yet will stand up to hard use when needed. Most of my blades are SR101 steel, which I've read can be difficult to relief grind and sharpen. I also have some folders that take a long time to form a burr when used with grit sizes that most people consider coarse, even when the edge has been thinned and sharpened before.

I started using an extra-coarse diamond benchstone thinking, from the description, that would be plenty coarse enough to remove metal quickly, but it went way too slowly for me (I don't like to use machines for this). I eventually moved into lower grit sizes, going into the extra-extra coarse diamond and 100-120 grit silicon carbide stones, then below that. Most of these stones were from well-known and respected manufacturers so I'm sure poor quality wasn't the issue. I don't think my lack of ability was the problem, either, as I do fairly well at freehand sharpening and have read about and researched this subject a lot.

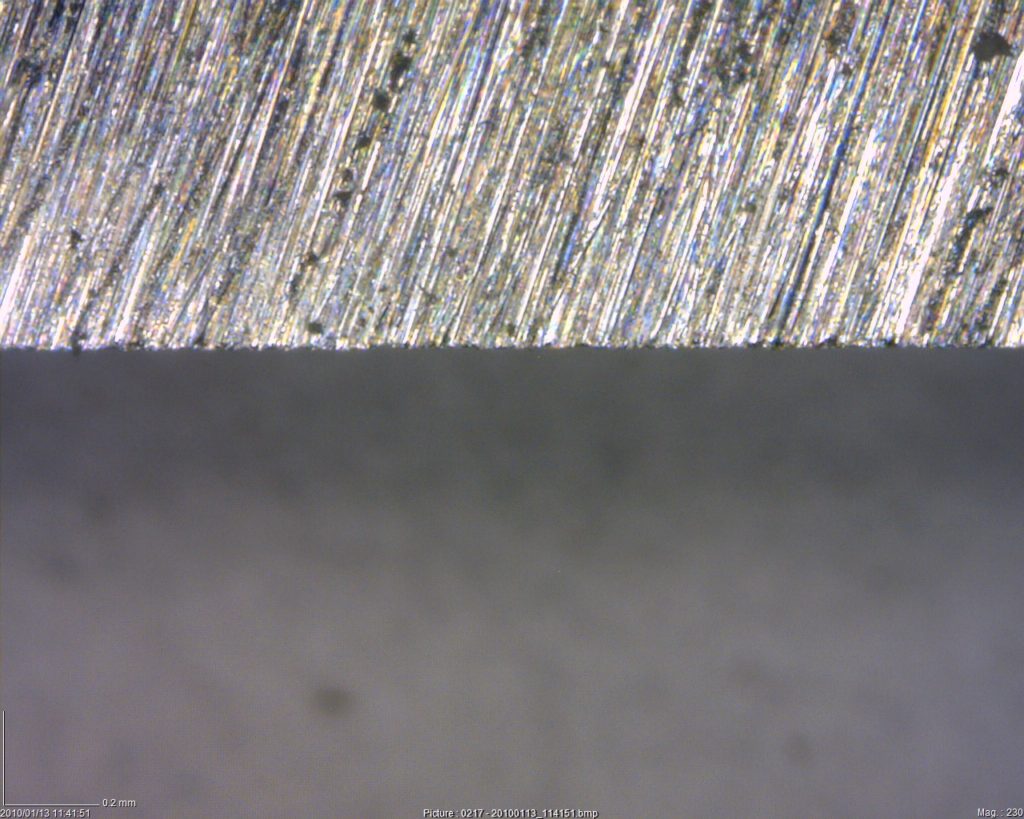

To make a long story short, after much trial and error, time, frustration, and considerable expense, I didn't get the results I wanted until I went to a 50 grit emery cloth. I can get a burr fairly quickly now, taking just a small fraction of the time it took with higher grits.

I know of at least two companies that sell 50 grit stones, so obviously some people use a grit this low. But, since I rarely read on this forum about anyone relief grinding and sharpening with such a low grit, I figure there must be some downsides to it.

So, that is my question. What are the negatives, if any, about using 50 grit as the starting grit for relief grinding and sharpening?

Thank you....

These knives (excluding kitchen knives) are mostly fixed-blade and used for more demanding chores around the house and in the wilderness. I am not interested in smooth, polished, refined edges, but utility, toothy, V-edges (finished at around 400-600 grit) that are thin enough to cut well, yet will stand up to hard use when needed. Most of my blades are SR101 steel, which I've read can be difficult to relief grind and sharpen. I also have some folders that take a long time to form a burr when used with grit sizes that most people consider coarse, even when the edge has been thinned and sharpened before.

I started using an extra-coarse diamond benchstone thinking, from the description, that would be plenty coarse enough to remove metal quickly, but it went way too slowly for me (I don't like to use machines for this). I eventually moved into lower grit sizes, going into the extra-extra coarse diamond and 100-120 grit silicon carbide stones, then below that. Most of these stones were from well-known and respected manufacturers so I'm sure poor quality wasn't the issue. I don't think my lack of ability was the problem, either, as I do fairly well at freehand sharpening and have read about and researched this subject a lot.

To make a long story short, after much trial and error, time, frustration, and considerable expense, I didn't get the results I wanted until I went to a 50 grit emery cloth. I can get a burr fairly quickly now, taking just a small fraction of the time it took with higher grits.

I know of at least two companies that sell 50 grit stones, so obviously some people use a grit this low. But, since I rarely read on this forum about anyone relief grinding and sharpening with such a low grit, I figure there must be some downsides to it.

So, that is my question. What are the negatives, if any, about using 50 grit as the starting grit for relief grinding and sharpening?

Thank you....