- Joined

- Feb 6, 2010

- Messages

- 1,427

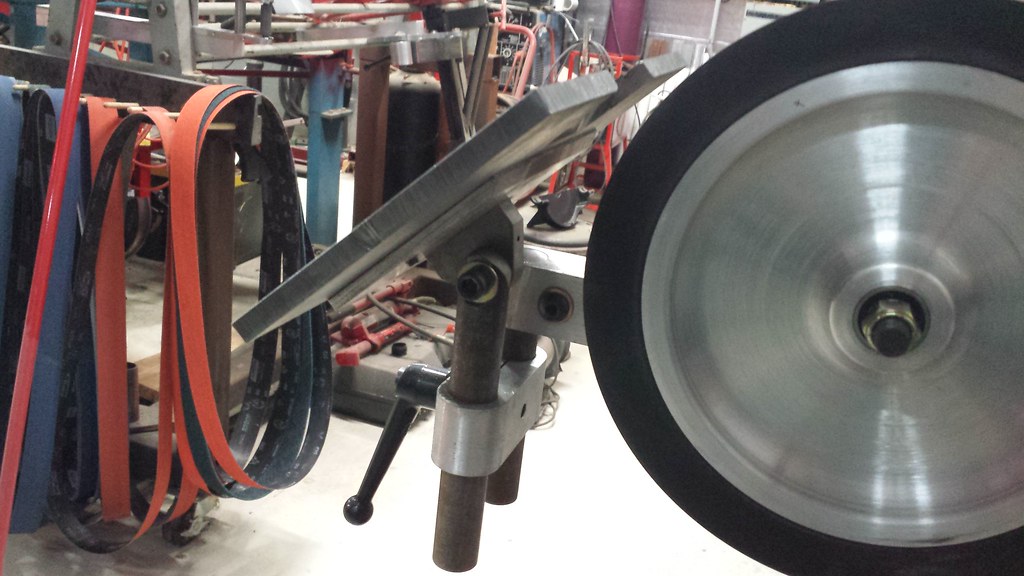

I first saw a tool rest similar to this on a post by Ranger Bob on this forum. He said he got the design from the Wilmont grinder rest. I have built at least five different rests for my grinders and I whipped this one out today. I post this because a lot of newer grinder designs have a second tool arm slot and this will fit them all if they use a 1 1/2 x 1 1/2 inch slot.

The bars are cold rolled 3/4 inch (6" and 12" ) and the adjustable handles are from McMaster Carr and have 3 1/2 handles and 3/4 inch of exposed 3/8-16 thread. The bottom bar is 5 1/4 inches long. I cut a slot with a portaband saw in the end of the aluminum toolbar after drilling a 3/4 inch hole. I bought all new materials and the cost was about $50 including the 20" toolbar and shipping. The rest plate is 1/2 aluminum and is 2 inches x about 7 inches. Maybe this will fill the bill for someone with a second tool arm slot. Larry

The bars are cold rolled 3/4 inch (6" and 12" ) and the adjustable handles are from McMaster Carr and have 3 1/2 handles and 3/4 inch of exposed 3/8-16 thread. The bottom bar is 5 1/4 inches long. I cut a slot with a portaband saw in the end of the aluminum toolbar after drilling a 3/4 inch hole. I bought all new materials and the cost was about $50 including the 20" toolbar and shipping. The rest plate is 1/2 aluminum and is 2 inches x about 7 inches. Maybe this will fill the bill for someone with a second tool arm slot. Larry