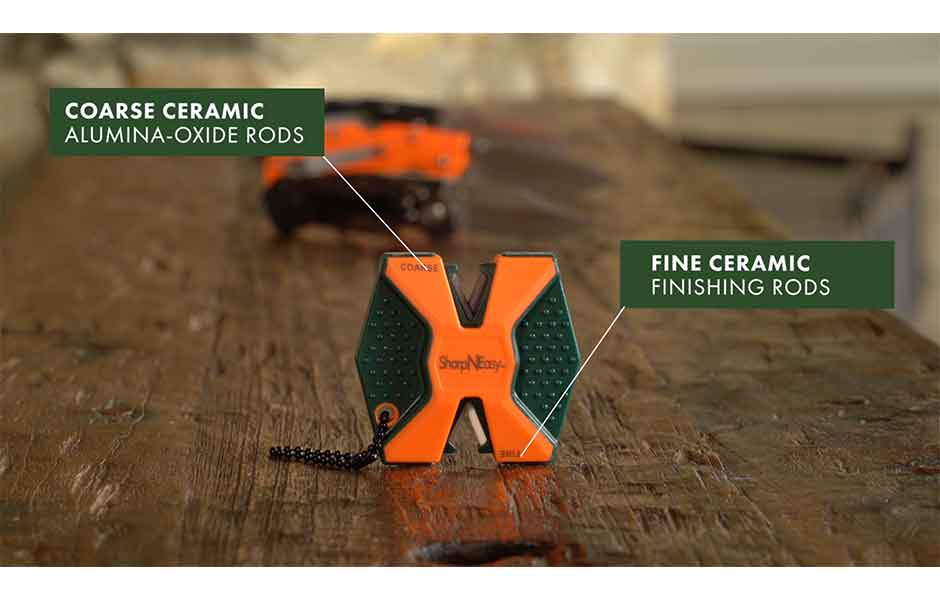

So normally I use my sharp maker (or, much less frequently bench stones) but I wanted something I can put in my BOB or micro-travel kit that would offer the easiest sharpening. Likewise I almost never use pull through type sharpeners for obvious reasons. Anyways, I found these two almost identical sharpeners from Accusharp of the pull through type (pn 336 and 017c). Super compact and what draws my attention is that neither uses a carbine blade destroyer. Both have "fine" ceramic finishing rods but one is a diamond "coarse" rod and the other a ceramic "coarse" rod. I figure when near-new the diamond will likely be a little more aggressive but any suggestions or thoughts on longevity of the diamond vs the ceramic versions? The rods are not removable not do they rotate so we are looking at a fairly finite lifespan either way I'm sure.

Interestingly, I have the 336 (ceramic, orange below) version already and it matches the factory bevels on my BM 940 perfectly.

Interestingly, I have the 336 (ceramic, orange below) version already and it matches the factory bevels on my BM 940 perfectly.