I'm having a conversation with a knife maker; he posts on this forum. I won't mention his name but he's free to chime in as necessary.

Heforges makes knives in three different steels; in no particular order: 80CRV2, AEB-L and CPM-154. 80CRV2 is a 1080+ type steel whereas AEB-L and CPM154 are SS; CPM154 being the powdered steel technology version of 154CM/ATS34.

He has a recommendation, but since our previous discussions have been private, I'll again let him decide if he wants to comment.

I'm not a fan of SS, probably because a) I've never had a good one (i.e. Gerber LMF-II/Prodigy in 420HC, yuck!) and b) I don't live on the ocean and don't worry about rust. The vast majority of my knives are ESEEs, Beckers, Cold Steel i.e. some form of carbon steel, etc. I used to own a RMK #5-5 in O1 but it didn't get used too much before it was stolen.

My priorities are a) Toughness and Edge Retention, b) sharpen ability (distant 3rd) and c) corrosion resistance (distant 4th). This knife will be primarily used for general camp/bushcraft use and skinning deer and hogs.

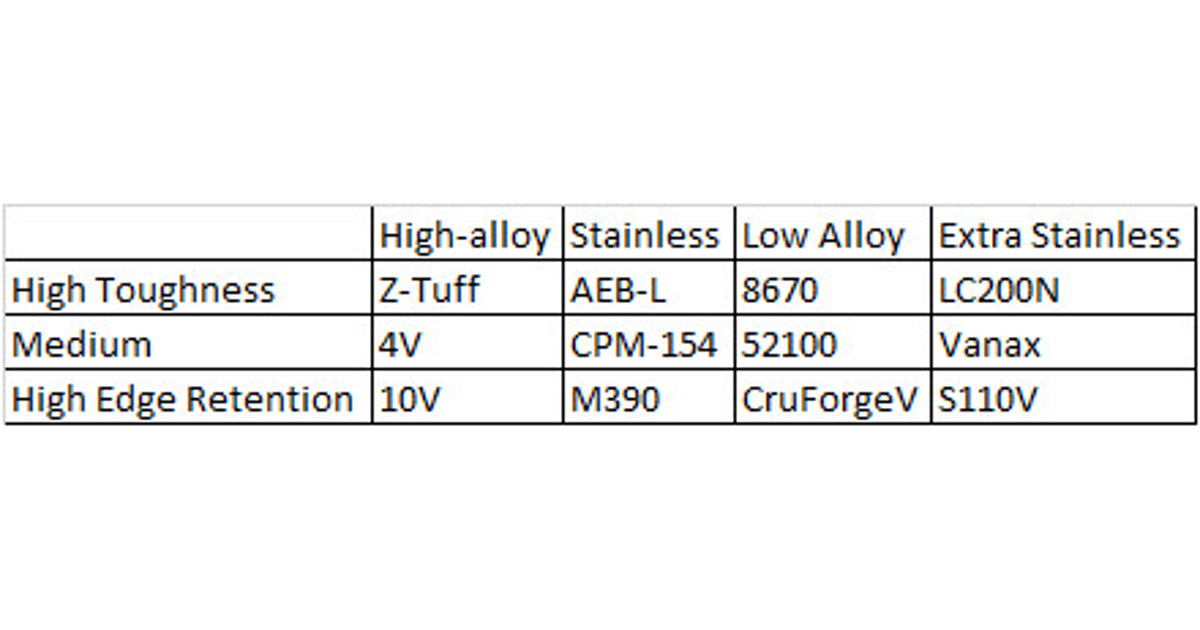

I've spent quite a bit of time over on the Knifenerds site gathering technical data and his opinions. These are summarized in the two pics below. The three steels in question are in red; data is shown for various other knife steels most of which I have owned and/or used.

Comments about these three steels from the knife makers here, especially compared to each other?

Thanks, I appreciate it!

He

He has a recommendation, but since our previous discussions have been private, I'll again let him decide if he wants to comment.

I'm not a fan of SS, probably because a) I've never had a good one (i.e. Gerber LMF-II/Prodigy in 420HC, yuck!) and b) I don't live on the ocean and don't worry about rust. The vast majority of my knives are ESEEs, Beckers, Cold Steel i.e. some form of carbon steel, etc. I used to own a RMK #5-5 in O1 but it didn't get used too much before it was stolen.

My priorities are a) Toughness and Edge Retention, b) sharpen ability (distant 3rd) and c) corrosion resistance (distant 4th). This knife will be primarily used for general camp/bushcraft use and skinning deer and hogs.

I've spent quite a bit of time over on the Knifenerds site gathering technical data and his opinions. These are summarized in the two pics below. The three steels in question are in red; data is shown for various other knife steels most of which I have owned and/or used.

Comments about these three steels from the knife makers here, especially compared to each other?

Thanks, I appreciate it!

Last edited: