Hengelo_77

Basic Member

- Joined

- Mar 2, 2006

- Messages

- 6,294

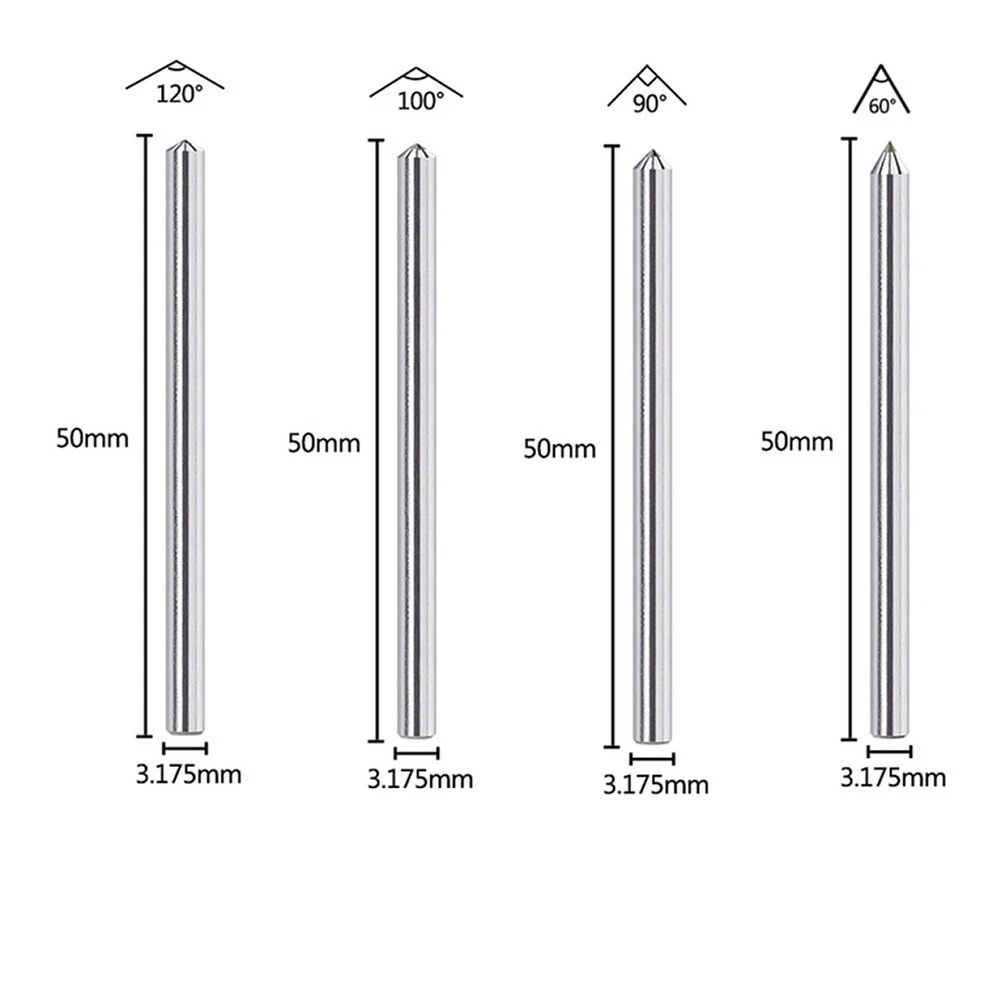

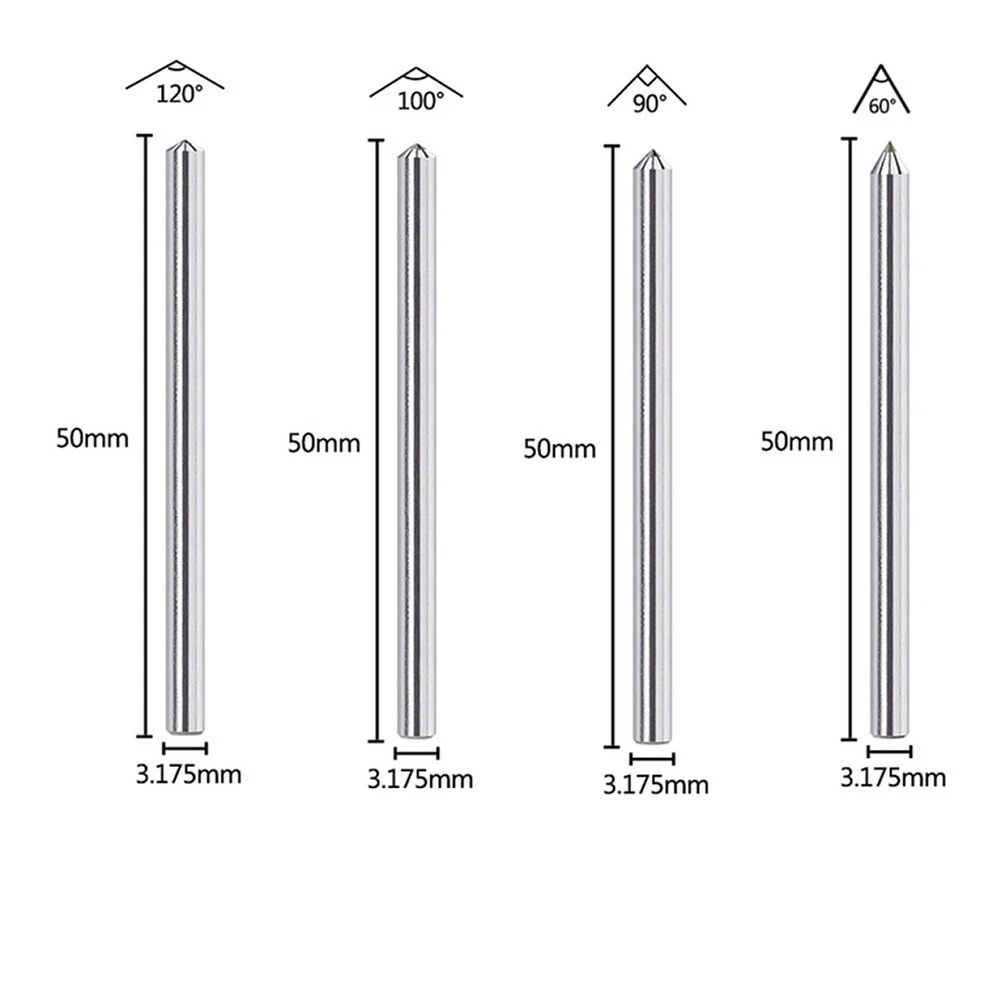

What angle would be best suited for engraving hardened stainless?

How do these different angles work, does a steeper angle go deeper in to the steel?

How do these different angles work, does a steeper angle go deeper in to the steel?