My second batch of S35VN has pretty much turned out like my first. Not hardening sufficiently. CPM154 is my primary steel and I have zero issues with my ht process, getting 60.5-61.0 every time. Figured I’d try the 35 and see what happens.

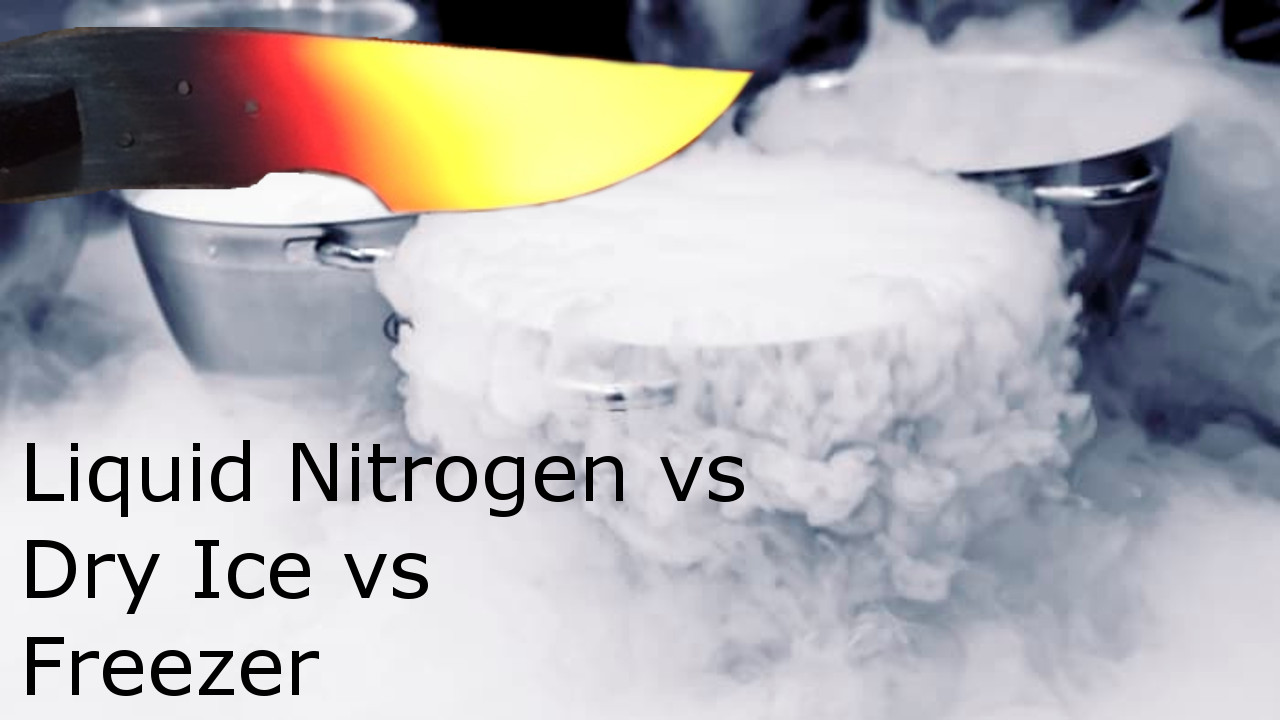

Both times my process has been: 1950 @ 30 minutes, aluminum plate quench and get into liquid N @ under ten minutes for two hours. Temper twice @ 400 degrees/2 hours. My hardness tester says 54-55 on the blades at the conclusion. I cant really point my finger at the oven….perfect results on other steels. Hardness tester? Test blocks say it’s on with my new diamond indenter. Made a test knife to see if it was my imagination and the diamond sharpener is just eating up the blade….it’s indeed soft. A shaving edge has proven to be impossible. Six blades trashed this time.

Pulling my hair out over this. I’ve never done this before but with my blades, could I anneal them and start the ht process over? Suggestions for next time? Thanks in advance guys.

Both times my process has been: 1950 @ 30 minutes, aluminum plate quench and get into liquid N @ under ten minutes for two hours. Temper twice @ 400 degrees/2 hours. My hardness tester says 54-55 on the blades at the conclusion. I cant really point my finger at the oven….perfect results on other steels. Hardness tester? Test blocks say it’s on with my new diamond indenter. Made a test knife to see if it was my imagination and the diamond sharpener is just eating up the blade….it’s indeed soft. A shaving edge has proven to be impossible. Six blades trashed this time.

Pulling my hair out over this. I’ve never done this before but with my blades, could I anneal them and start the ht process over? Suggestions for next time? Thanks in advance guys.