AFAustin

Gold Member

- Joined

- Jun 8, 2004

- Messages

- 2,505

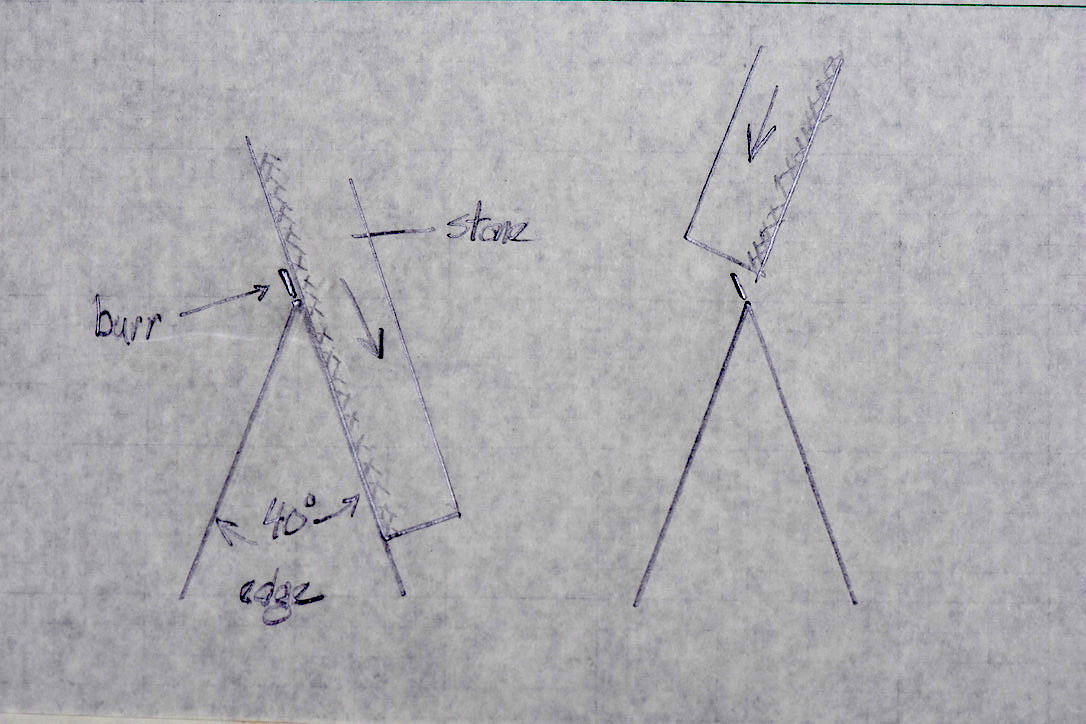

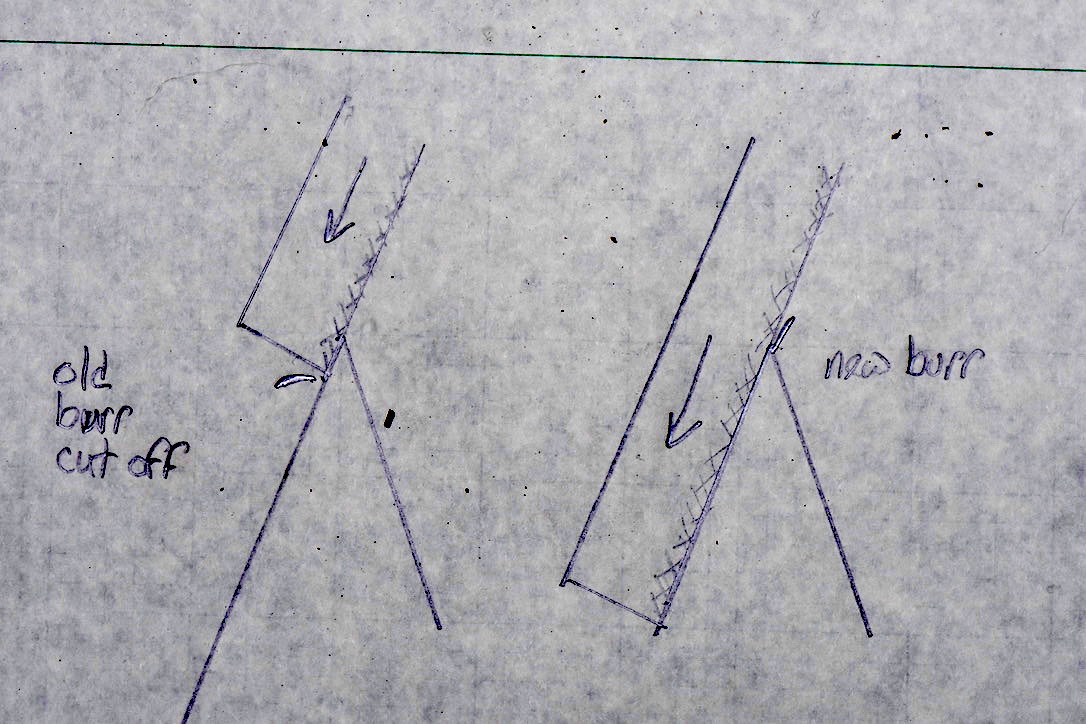

Most of my knives are traditional slipjoints or small lockbacks, and a lot of them have softer stainless steel, e.g., Case's Tru Sharp 420HC. They will take a very fine edge but sometimes can develop a really stubborn burr. When that happens, I'll try all the usual methods of burr removal: progressively light strokes on Spyderco UF rods; a couple of higher angle passes; drawing through cork or hard felt; stropping on denim with a variety of compounds, etc. But I'd love to find something quicker and more effective.

I've seen David (OWE) and others talk about diamonds having the advantage of leaving minimal or no burrs, which made me wonder about another possible method. My soft steel knives don't need the coarser diamonds for routine sharpening, but when those stubborn burrs happen, what about using a DMT Extra Extra-Fine pocket stone? They are rated as 8000 mesh/3 micron. Unfortunately, very few DMT stones are available in the Extra-Extra Fine. But there is a 4-inch "Diamond Whetstone" with the interrupted surface. I've never used DMT's interrupted surface stones, and it seems like it might be awkward to use them with edge leading strokes on small, thin, pointy traditional slipjoints. But what about using one as a "strop" with a few edge trailing strokes? Might that defeat the stubborn burrs?

Thanks for any advice.

Andrew

I've seen David (OWE) and others talk about diamonds having the advantage of leaving minimal or no burrs, which made me wonder about another possible method. My soft steel knives don't need the coarser diamonds for routine sharpening, but when those stubborn burrs happen, what about using a DMT Extra Extra-Fine pocket stone? They are rated as 8000 mesh/3 micron. Unfortunately, very few DMT stones are available in the Extra-Extra Fine. But there is a 4-inch "Diamond Whetstone" with the interrupted surface. I've never used DMT's interrupted surface stones, and it seems like it might be awkward to use them with edge leading strokes on small, thin, pointy traditional slipjoints. But what about using one as a "strop" with a few edge trailing strokes? Might that defeat the stubborn burrs?

Thanks for any advice.

Andrew