Fred.Rowe

Knifemaker / Craftsman / Service Provider

- Joined

- May 2, 2004

- Messages

- 6,848

Help me out here guys

The ERU is a work in progress and I'm always looking for ways to improve on the original. I posted here in maintenance wanting feedback from you folks, who understand sharp. Someone's post on this forum prompted this advancement.

The inserts in the ERU are set using a precision square; they are set along both axis relative to the degree indicator. This is not accurate enough; the human eye won't produce the accuracy needed. To reach its potential the carbide inserts must be lapped after they are mounted in the individual aluminum disc.

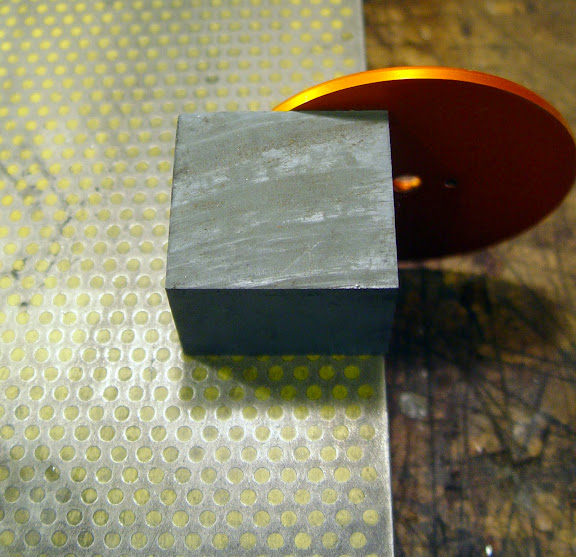

The fixture pictured below allows the carbide surfaces to be lapped, on a diamond plate, square relative to the sharpeners axis. The result is more surface area abrading the edge when drawing a blade is pulled through the carbide "V". It's pushed the degree of sharp up a considerable amount from the mechanical setting.

This sharpener, with its carbide inserts lapped on a diamond plate will produce shaving sharp edges without stropping. I was amazed at the difference from the original.

Thanks for your input, it has been invaluable, Fred

Who ever has the ERU on the passaround here on BF, if you have a diamond plate would you lap the carbide surfaces in the manner shown? If you don't have a diamond plate ship it to me and I'll do the work.

If you purchased an ERU from the first run of 50, [orange] contact me or drop your sharpener in the mail and I will lap the inserts and return it to you.

The ERU is a work in progress and I'm always looking for ways to improve on the original. I posted here in maintenance wanting feedback from you folks, who understand sharp. Someone's post on this forum prompted this advancement.

The inserts in the ERU are set using a precision square; they are set along both axis relative to the degree indicator. This is not accurate enough; the human eye won't produce the accuracy needed. To reach its potential the carbide inserts must be lapped after they are mounted in the individual aluminum disc.

The fixture pictured below allows the carbide surfaces to be lapped, on a diamond plate, square relative to the sharpeners axis. The result is more surface area abrading the edge when drawing a blade is pulled through the carbide "V". It's pushed the degree of sharp up a considerable amount from the mechanical setting.

This sharpener, with its carbide inserts lapped on a diamond plate will produce shaving sharp edges without stropping. I was amazed at the difference from the original.

Thanks for your input, it has been invaluable, Fred

Who ever has the ERU on the passaround here on BF, if you have a diamond plate would you lap the carbide surfaces in the manner shown? If you don't have a diamond plate ship it to me and I'll do the work.

If you purchased an ERU from the first run of 50, [orange] contact me or drop your sharpener in the mail and I will lap the inserts and return it to you.

Last edited: