Hi John,

Yeah, I had to comment.

From where I sit, there are three opportunities to look at this knife and make observations.

STeven, thanks for taking the time to study the post and post some dialogue for discussion. I appreciate that. I'll respond to your three points with a little insight into why I did those things the way I did. It doesn't mean I was right (or wrong) as so much of it is preference and opinion but at least it'll be some commentary on 'why'. On almost every aspect of making a knife, I give quite a bit of thought and care. Very little is done randomly, from lines and proportions to finishes and textures to materials and details. So most of these things you mention I have actually given thought to.

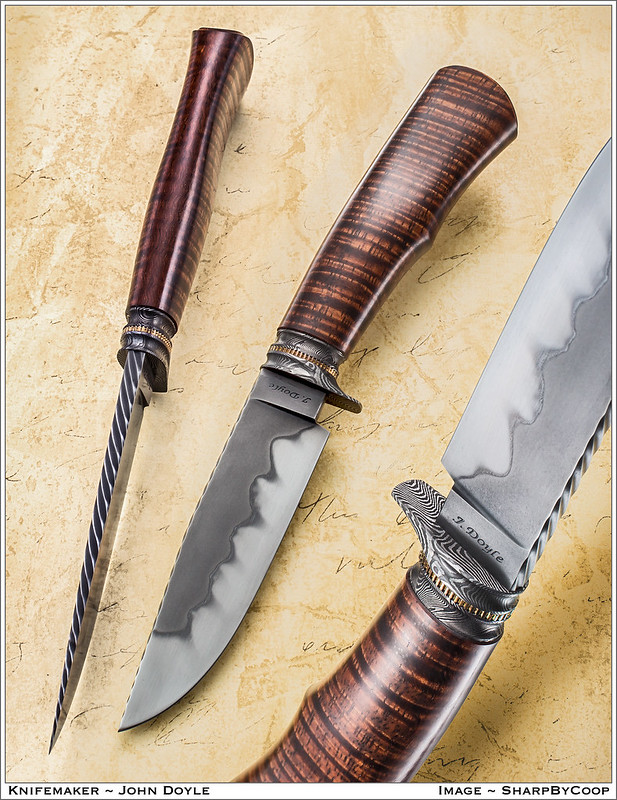

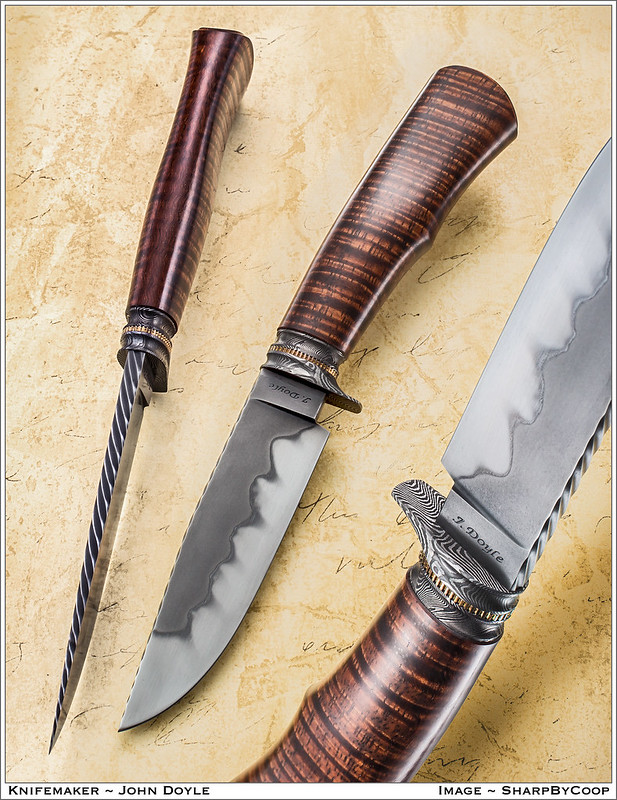

1. The blade, solely the finish......this is the hamon/etched version of a bead blasted blade on a dress handle. It can often work....think Hanson Scary Tac, or a handle with really electric titanium anodizing....but this handle is a classic refined hunter...with some killer details. From the fluted rim at the handle end the inset assembly finial, to the damascus guard with flute and 1/2 flute....the details are there...but then you have a bold hamon that is languishing under a huge coating of oxide.

Likely that this hamon will never "pop" the way that it could and while I understand it likely that the purchaser wanted a using knife....this is not the best finish for the blade. The reason being is that you kind of polished the hamon area and left the soft back dark gray....so if there is darkening with blood, it's likely to simply color the hardened portion to the point where both the soft and the hard are relatively indistinguishable. IMO, this one called for a satin polish of some sort, pulling the oxides out of the soft portion and allowing for a subtle but powerful contrast between the Martinsite and the Pearlite...there would likely be a shimmer/chatoyancy that is probably missing now, one of the most compelling aspects of a hamon.

There is no doubt that the dark etch on blades like this mask or even kill some of the fine subtle activity in the hamon. Most of my dark blades, as I'm sanding and polishing prior to etching have crazy activity.

This finish is HIGHLY requested from me...in fact I would safely say that at least 4 out of every 5 knives I make are requested to have the 'two-tone gray blade with black hamon line' almost verbatim in most cases. It's not as crude of a finish as it might appear at first glance. And it does have it's own intricacies in different lighting too. It's more refined than just etching it for 5 minutes, wiping off the crud and calling it good (I've seen a fair amount of that). When I first started doing it, it was probably a little cruder than it is now. I've refined my techniques and polishing methods and my skills have improved and the process is still a multiple cycle etch/polish process that takes anywhere from 3 hours to half a day depending on how much activity is in there.

The bottom line is if it gets requested, I don't mind doing it. HOWEVER...I'm pretty meticulous with finishes and I wouldn't put that finish on a blade just because it was requested if I was satisfied with how it looks. It would never leave my shop if I wasn't okay with it.

That said, my brighter, more satin polishes are improving too and I've come to have a better understanding and more appreciation for the more traditional look that offers too. I hope to have some more blades that are more polished in the near future.

2. The filework....rope pattern is always good as an homage to the '70's/80's...but this design seems more modern and refined than that, so symmetrical filework(arrowheads, crosses, x's.....) might have been a possibility. That said, always a good idea to end the filework at the 2/3's point of the blade, that way it doesn't run the risk of dominating as it does here.

First off, I don't mind the rope filework on this piece. I don't think it makes it look dated at all. In fact, arrowheads or crosses or x's might be more appropriate for a period piece or historical/traditional replica....at least to my mind. I do my 'rope' a little different than most in the fact that I eliminate the saw cut between the round file cuts. I found the saw cuts left sharp little corners that dug into the thumb. This is more of just a 'twisted steel' look. I think it is elegant and refined. I can assure you that this filework is well done and precise.

As for the termination point...I can see your point...and I gave that some consideration as well. If this knife had a swedge or false edge, it would have been a good call to have the filework stop at the corner on the spine where the straight spine stops and drops to the clip. The swedge could then start there where the filework stops. That makes perfect sense to me and in fact, I have one in the works where that is exactly the case.

Being that this is a clip point blade but doesn't have a false edge, neither stopping the filework at the corner without having some other detail to terminate it at nor running the filework past the corner but not going near all the way to the tip seemed like a good idea. If I had run the filework past the corner to say 2/3's the length of the spine ( I realize 2/3's was just an arbitrary figure you threw out there) it would have just stopped halfway down the clip. And that's what I was specifically trying to avoid. I didn't want it to look like I just stopped and didn't finish the pattern out to some natural or logical terminus.

Filework is always going to be a preference thing. For as many suggestions as you get to do it one way, you'll find the same number of folks that would want it the opposite way.

3. This is purely opinion, but the butt of the handle is wide enough that it seems to aesthetically dominate the flow of the knife.

I'll not be shy about saying that I think you're flat out wrong here.

. Proportions are something I give a great deal of consideration to, especially in this area. I like to make the butt end of the handle, just slightly taller from top to bottom than the finger hook area at the midpoint of the handle, and the midpoint hook taller slightly than the ricasso/spacer height. This gives everything a nice gentle downward fall to the handle and leaves pleasing lines. On a handle such as this type, I feel aesthetically that the butt end needs to be the widest and any part of the handle going forward needs to be slightly narrower than area right behind it. To me it looks funny if it's not, certain modern folders excluded where the front of the handle is the widest part and it tapers to a narrow butt end.

In this case, I just measured the paper pattern that is still laying on my finishing bench and the butt end of the handle measures just shy of 1 1/4", the mid handle hook measures 1 1/8" and the spacer measures 7/8" tall. I realize that a little change can make a big difference but there isn't a lot of room to change much there without looking funny. Also, my hunter handles are surprisingly slim and nicely contoured and almost all the feedback I've gotten is that they feel great in hand.

Thanks for reading, and as always, am very interested in your responses. Regardless of your responses, it has been a joy to see you persevere and become a consistently proficient bladesmith and knifemaker.

Best Regards,

STeven Garsson

I appreciate this. I really do. I value your input into this forum and the knife community as a whole and I value your dedication to these discussions. Even if we disagree, which is really less often than not, I still like the commentary and discussion and it's always food for thought. Thanks for posting your comments. :thumbup: