- Joined

- Mar 10, 2011

- Messages

- 2,681

I tried to parse out a condensed history from the "Mann Axe Dynasty of Central Pennsylvania"

https://sites.psu.edu/jpn2016/files/2016/11/Mann-Axe-Dynasty-of-Central-Pennsylvania_Rev-2hutwhk.pdf

I've also included two patents that I thought were interesting.

William Mann Sr made edge tools in Johnstown, NY.

Two of his sons William Jr and Harvey start production in 1825 in Bellefonte, PA.

In 1834 William Jr sells out to Harvey who continues the business.

In 1835 William Jr builds a factory

Two of William Jr's sons join his business, one is Robert.

Robert leaves in 1847 and starts his own factory in 1849.

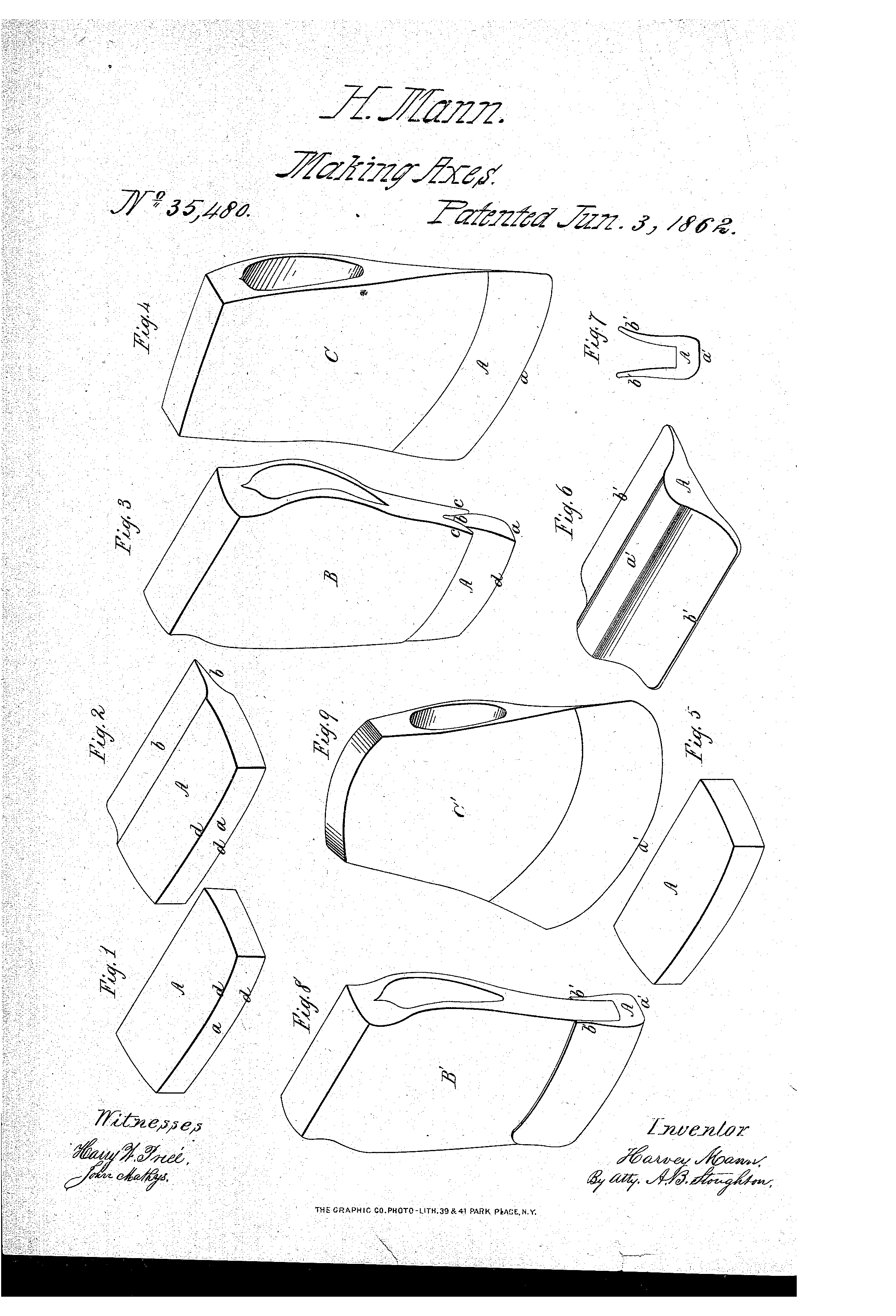

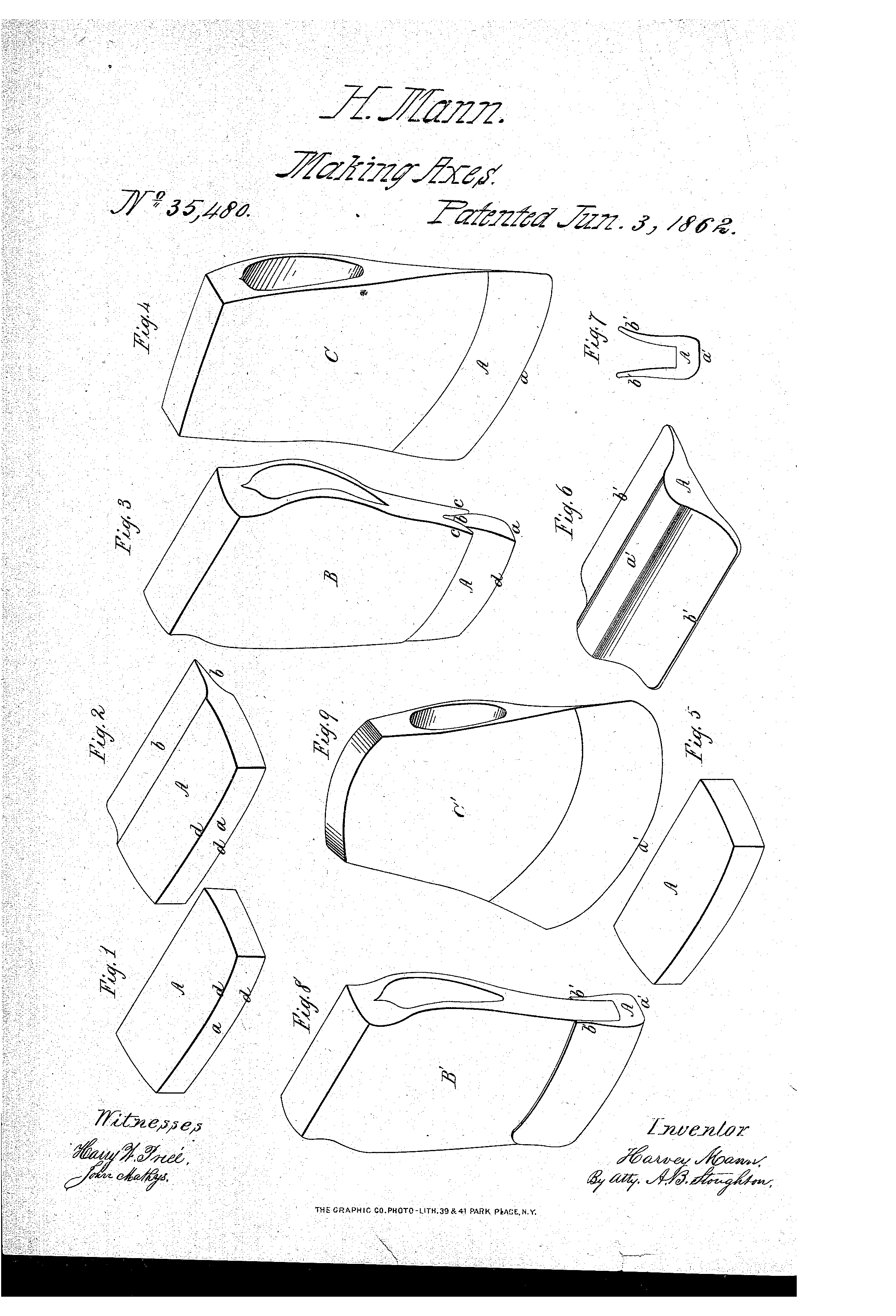

In 1862 Harvey patents the overlay method.

https://www.google.com/patents/US35480

"By 1879, three of Robert’s sons had joined the business." One is Joseph.

Robert's business was sold to the "Axe Trust" ca 1889

William Jr's business was sold to the "Axe Trust" in 1890

Harvey's business was sold to the "Axe Trust" in 1892

In 1893 Joseph is president of the new MANN EDGE TOOL CO. at Lewistown.

Patent of Joseph R. Mann No. 561,409 June 2, 1896

http://www.google.sr/patents/US561409

Bob

https://sites.psu.edu/jpn2016/files/2016/11/Mann-Axe-Dynasty-of-Central-Pennsylvania_Rev-2hutwhk.pdf

I've also included two patents that I thought were interesting.

William Mann Sr made edge tools in Johnstown, NY.

Two of his sons William Jr and Harvey start production in 1825 in Bellefonte, PA.

In 1834 William Jr sells out to Harvey who continues the business.

In 1835 William Jr builds a factory

Two of William Jr's sons join his business, one is Robert.

Robert leaves in 1847 and starts his own factory in 1849.

In 1862 Harvey patents the overlay method.

https://www.google.com/patents/US35480

"By 1879, three of Robert’s sons had joined the business." One is Joseph.

Robert's business was sold to the "Axe Trust" ca 1889

William Jr's business was sold to the "Axe Trust" in 1890

Harvey's business was sold to the "Axe Trust" in 1892

In 1893 Joseph is president of the new MANN EDGE TOOL CO. at Lewistown.

Patent of Joseph R. Mann No. 561,409 June 2, 1896

http://www.google.sr/patents/US561409

Bob