- Joined

- Jul 31, 2017

- Messages

- 1,478

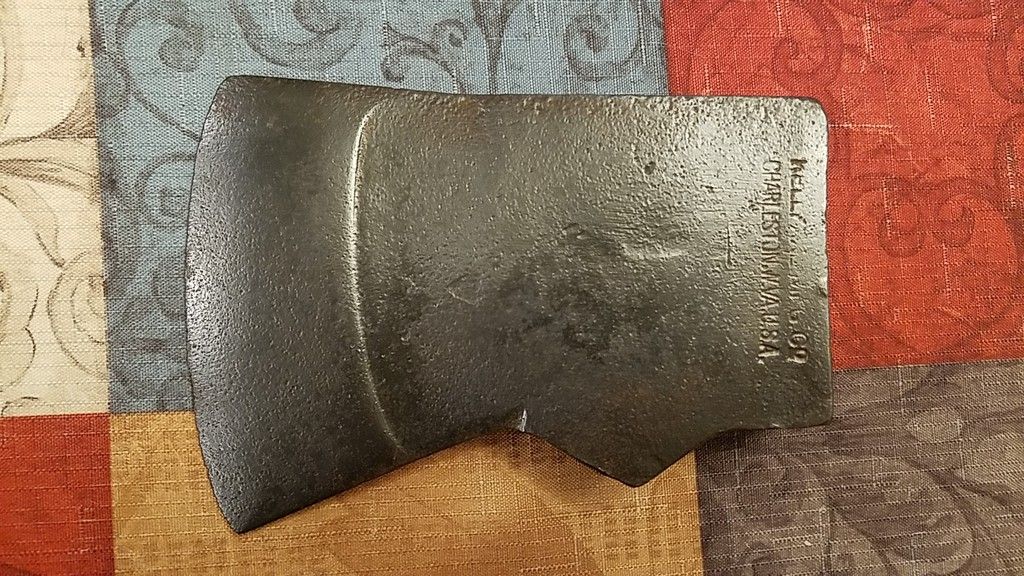

Do you know if anybody manufactured and offered to blacksmiths V-shaped, ready to be slapped on overcoat bit kits?

I am looking at those two axes and have feeling that both were given new life with factory produced overlaid bits. What do you think?

https://www.ebay.com/itm/Vtg-Old-Rusty-Antique-Iron-Axe-Head-Kelly-Axe-amp-Tool-Co-Marked-True-Temper-USA-/123764736253?hash=item1cd0f400fd:g:4M8AAOSwXdpczkg9&nma=true&si=wTTLdVrmmoXoY4f1IkFVlutOrSg%3D&orig_cvip=true&nordt=true&rt=nc&_trksid=p2047675.l2557

https://www.ebay.com/itm/KELLY-AXE-...m43663.l44720&nordt=true&rt=nc&orig_cvip=true

I am looking at those two axes and have feeling that both were given new life with factory produced overlaid bits. What do you think?

https://www.ebay.com/itm/Vtg-Old-Rusty-Antique-Iron-Axe-Head-Kelly-Axe-amp-Tool-Co-Marked-True-Temper-USA-/123764736253?hash=item1cd0f400fd:g:4M8AAOSwXdpczkg9&nma=true&si=wTTLdVrmmoXoY4f1IkFVlutOrSg%3D&orig_cvip=true&nordt=true&rt=nc&_trksid=p2047675.l2557

https://www.ebay.com/itm/KELLY-AXE-...m43663.l44720&nordt=true&rt=nc&orig_cvip=true

Last edited: