Just had this arrive :thumbup:

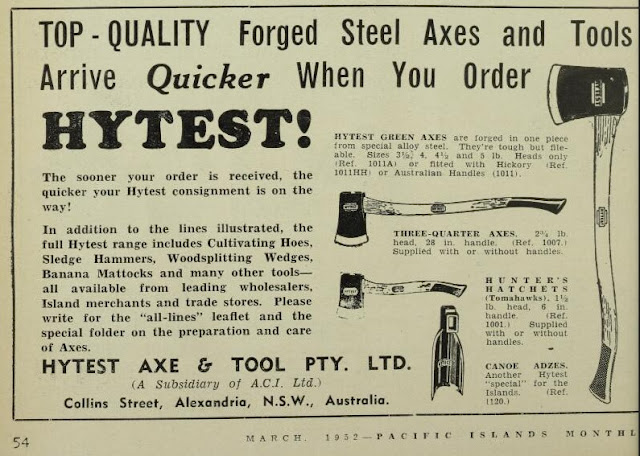

Its a Hytest Hatchet, which as far as a I can tell are quite rare.

What I think is awesome about this (other than being a hytest which is cool in itself) is that's its a real axe shaped hatchet complete with beveled cheeks etc.

At just over 5 inches long this IMO, is one bad ass hatchet complete with features often only found on real / quality full size axes. Many hatchets are just simple wedges/small ASO's. (which generally work fine for a hatchet)

Behold

The handle is a bit loose and the head does not sit quite straight. I havent decided what im going to do with the handle as yet if ill try to salvage it or rehang it on a fresh handle...will probably go the new handle route but we will see what it looks like when I take the head off and see what I have to work with.

Its a Hytest Hatchet, which as far as a I can tell are quite rare.

What I think is awesome about this (other than being a hytest which is cool in itself) is that's its a real axe shaped hatchet complete with beveled cheeks etc.

At just over 5 inches long this IMO, is one bad ass hatchet complete with features often only found on real / quality full size axes. Many hatchets are just simple wedges/small ASO's. (which generally work fine for a hatchet)

Behold

The handle is a bit loose and the head does not sit quite straight. I havent decided what im going to do with the handle as yet if ill try to salvage it or rehang it on a fresh handle...will probably go the new handle route but we will see what it looks like when I take the head off and see what I have to work with.

Last edited: