Day One: Stay awhile and listen...

Hey Gang,

Ive wanted to post this for a couple weeks now but Ive been busy and havent had a chance to get the details and photos put together. I figured some of you would enjoy it though, so Im probably going to post this in parts to get it out there.

As the title implies I was fortunate enough to take the ABS Intro to Bladesmithing course that was held here in Ohio several weeks ago. While Im still new to bladesmithing the driver behind my wanting to take this class was due to the difficulties I had in trying to forge anything knife shaped. I could hammer out a decent profile but to me that was not really worth the time and coal it took, when I could use my grinders and saws to do the same work a lot quicker. I was looking to forge close to finish

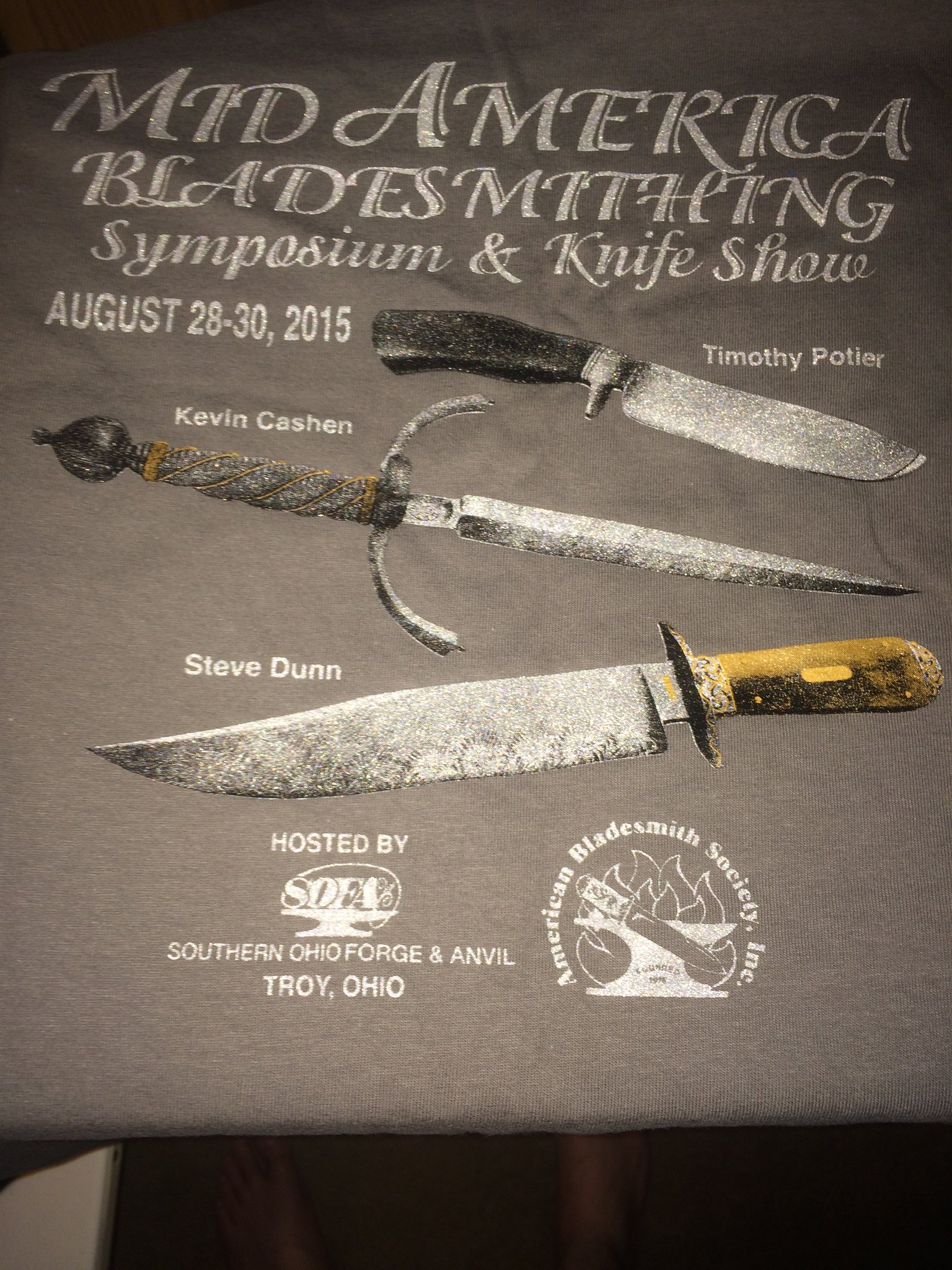

Enter the ABS course. The course was held at SOFA a large blacksmithing organization in Ohio that I check from time to time for events. I was late to the game finding out about the course only a month before the start but I found out there was a slot open so I jumped on it. I had to make some arrangements to be sure it was a go and my money didnt end up arriving until a few days before the course started, the guys at SOFA are first class, they made sure this wasnt a problem.

The master smith teaching the class was Timothy Potier, The Ragin Cajun. And he was indeed both a master and a Cajun Ill admit to having a little nervousness showing up the first day. Due to what I stated above I hadnt used the forge much so I was worried Id be out of practice or worse out of shape lol. Two weeks of hammer swinging is a lot. But it all worked out in the end.

Ill admit to having a little nervousness showing up the first day. Due to what I stated above I hadnt used the forge much so I was worried Id be out of practice or worse out of shape lol. Two weeks of hammer swinging is a lot. But it all worked out in the end.

After some introductions class started with a lecture from Timothy on basic knife, steel and heat treating fundamentals. I was educated on much of this but I went to this class as a "tabula rasa". I intended to soak up every bit of knowledge I could. After the lecture we got to watch Timothy forge a small hunter.

(Apologies I have a new phone and some of the photos are out of focus)

IMG_0099 by Clint, on Flickr

IMG_0099 by Clint, on Flickr

IMG_0098 by Clint, on Flickr

IMG_0098 by Clint, on Flickr

Once you see him start swinging on hot metal I could sense the excitement and giddiness of my four fellow classmates. Immediately I realized I got my moneys worth just a few hours in. After getting the blade close to the 80% finished mark we were told to go fire up our coal forges.

IMG_0089 by Clint, on Flickr

IMG_0089 by Clint, on Flickr

I got the 1075 heated up and started hammering. It was recommended we use our own hammers (but their great Tom Tongs) and I was surprised how much my 40$ Amazon smithing hammer grew on me. After some slow going we started to produce some knife shaped objects.

IMG_0091 by Clint, on Flickr

IMG_0091 by Clint, on Flickr

IMG_0093 by Clint, on Flickr

IMG_0093 by Clint, on Flickr

I planned on taking a lot more photos but honestly I was so focused on learning I had to make myself stop and pull out my phone. I forged much of the blade as a 3 foot bar then cut it and shaped the tang. No wasted metal here!

Thats about it for day one. The class moved quick after this. The goal was to get you geared up for week two which was making your chopper and going through the testing process. And I found out on day two my class would be shortened by a day that week. This was a bummer but turned out to be a blessing in disguise. More on that later

Thanks for following along and feel free to ask questions.

-Clint

ABS Apprentice

SOFA Member

Hey Gang,

Ive wanted to post this for a couple weeks now but Ive been busy and havent had a chance to get the details and photos put together. I figured some of you would enjoy it though, so Im probably going to post this in parts to get it out there.

As the title implies I was fortunate enough to take the ABS Intro to Bladesmithing course that was held here in Ohio several weeks ago. While Im still new to bladesmithing the driver behind my wanting to take this class was due to the difficulties I had in trying to forge anything knife shaped. I could hammer out a decent profile but to me that was not really worth the time and coal it took, when I could use my grinders and saws to do the same work a lot quicker. I was looking to forge close to finish

Enter the ABS course. The course was held at SOFA a large blacksmithing organization in Ohio that I check from time to time for events. I was late to the game finding out about the course only a month before the start but I found out there was a slot open so I jumped on it. I had to make some arrangements to be sure it was a go and my money didnt end up arriving until a few days before the course started, the guys at SOFA are first class, they made sure this wasnt a problem.

The master smith teaching the class was Timothy Potier, The Ragin Cajun. And he was indeed both a master and a Cajun

After some introductions class started with a lecture from Timothy on basic knife, steel and heat treating fundamentals. I was educated on much of this but I went to this class as a "tabula rasa". I intended to soak up every bit of knowledge I could. After the lecture we got to watch Timothy forge a small hunter.

(Apologies I have a new phone and some of the photos are out of focus)

IMG_0099 by Clint, on Flickr

IMG_0099 by Clint, on Flickr IMG_0098 by Clint, on Flickr

IMG_0098 by Clint, on FlickrOnce you see him start swinging on hot metal I could sense the excitement and giddiness of my four fellow classmates. Immediately I realized I got my moneys worth just a few hours in. After getting the blade close to the 80% finished mark we were told to go fire up our coal forges.

IMG_0089 by Clint, on Flickr

IMG_0089 by Clint, on FlickrI got the 1075 heated up and started hammering. It was recommended we use our own hammers (but their great Tom Tongs) and I was surprised how much my 40$ Amazon smithing hammer grew on me. After some slow going we started to produce some knife shaped objects.

IMG_0091 by Clint, on Flickr

IMG_0091 by Clint, on Flickr IMG_0093 by Clint, on Flickr

IMG_0093 by Clint, on FlickrI planned on taking a lot more photos but honestly I was so focused on learning I had to make myself stop and pull out my phone. I forged much of the blade as a 3 foot bar then cut it and shaped the tang. No wasted metal here!

Thats about it for day one. The class moved quick after this. The goal was to get you geared up for week two which was making your chopper and going through the testing process. And I found out on day two my class would be shortened by a day that week. This was a bummer but turned out to be a blessing in disguise. More on that later

Thanks for following along and feel free to ask questions.

-Clint

ABS Apprentice

SOFA Member

Last edited: