- Joined

- Jan 27, 2008

- Messages

- 2,010

Rumors of my demise, although becoming increasingly more likely with each passing day, are still greatly exaggerated. I'm still making knives and I thought I'd show a selection of my work of the past while. My apologies for the reallllly blurry photos.

-Peter

Unnamed

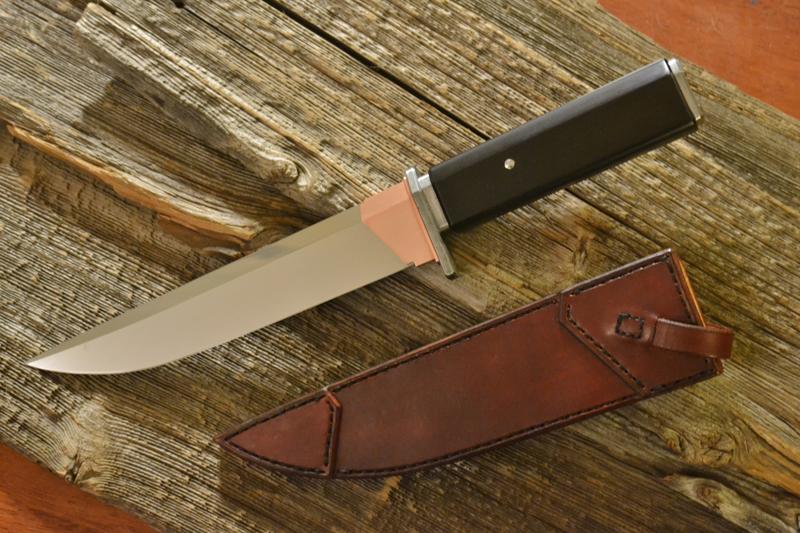

3 3/4" of 1084, Ebony and Oak:

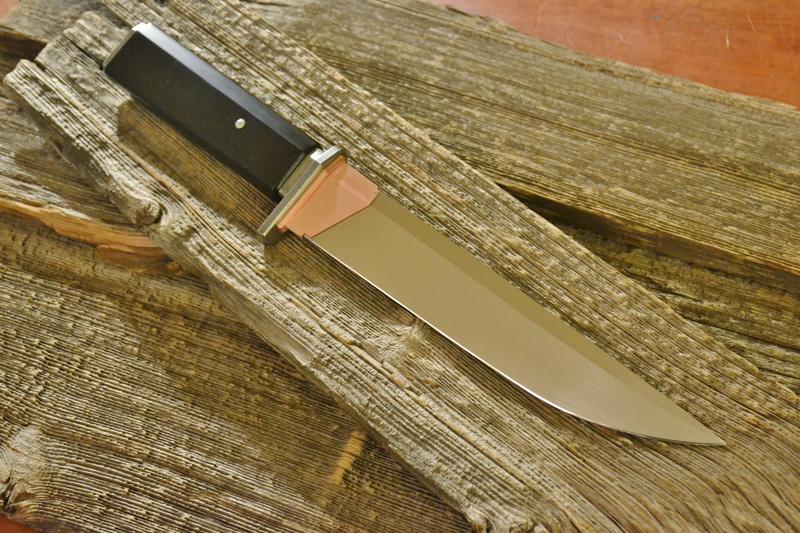

"Send It" (built for a "retiring" JTF2 soldier):

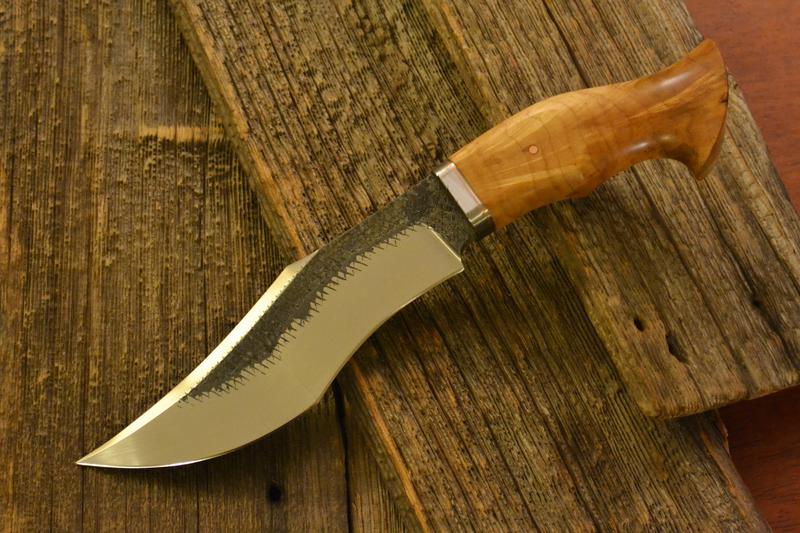

4" of 1084, Cape Breton Red Maple burl, Moose bone, ebony accents:

Barachois Hunter #1

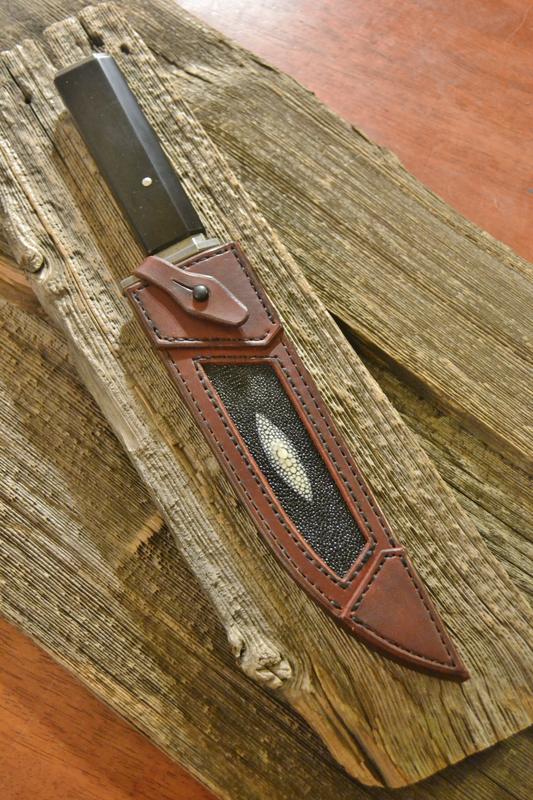

5" of 1084, African Blackwood, and figured Red Palm:

-Peter

Unnamed

3 3/4" of 1084, Ebony and Oak:

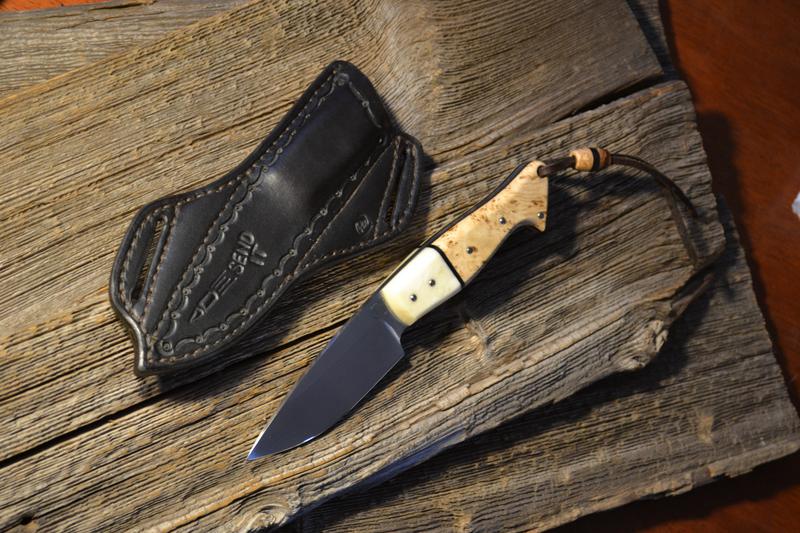

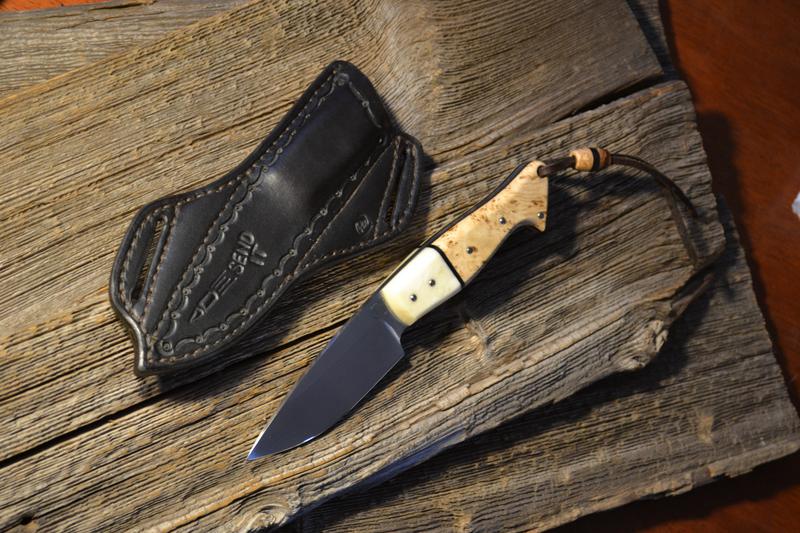

"Send It" (built for a "retiring" JTF2 soldier):

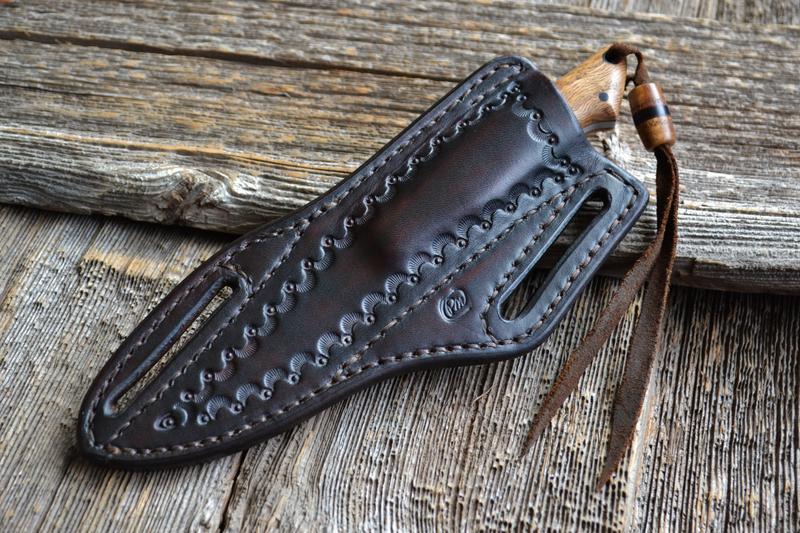

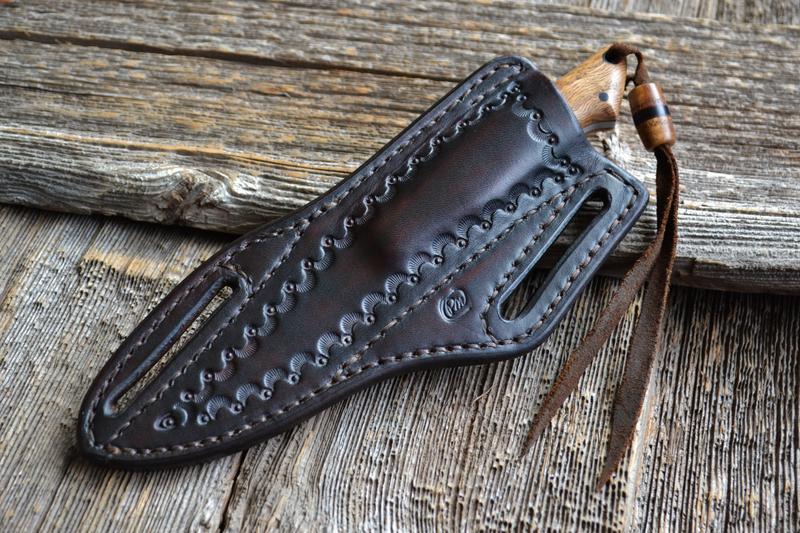

4" of 1084, Cape Breton Red Maple burl, Moose bone, ebony accents:

Barachois Hunter #1

5" of 1084, African Blackwood, and figured Red Palm:

Last edited: