- Joined

- Jun 11, 2010

- Messages

- 489

Hey everyone,

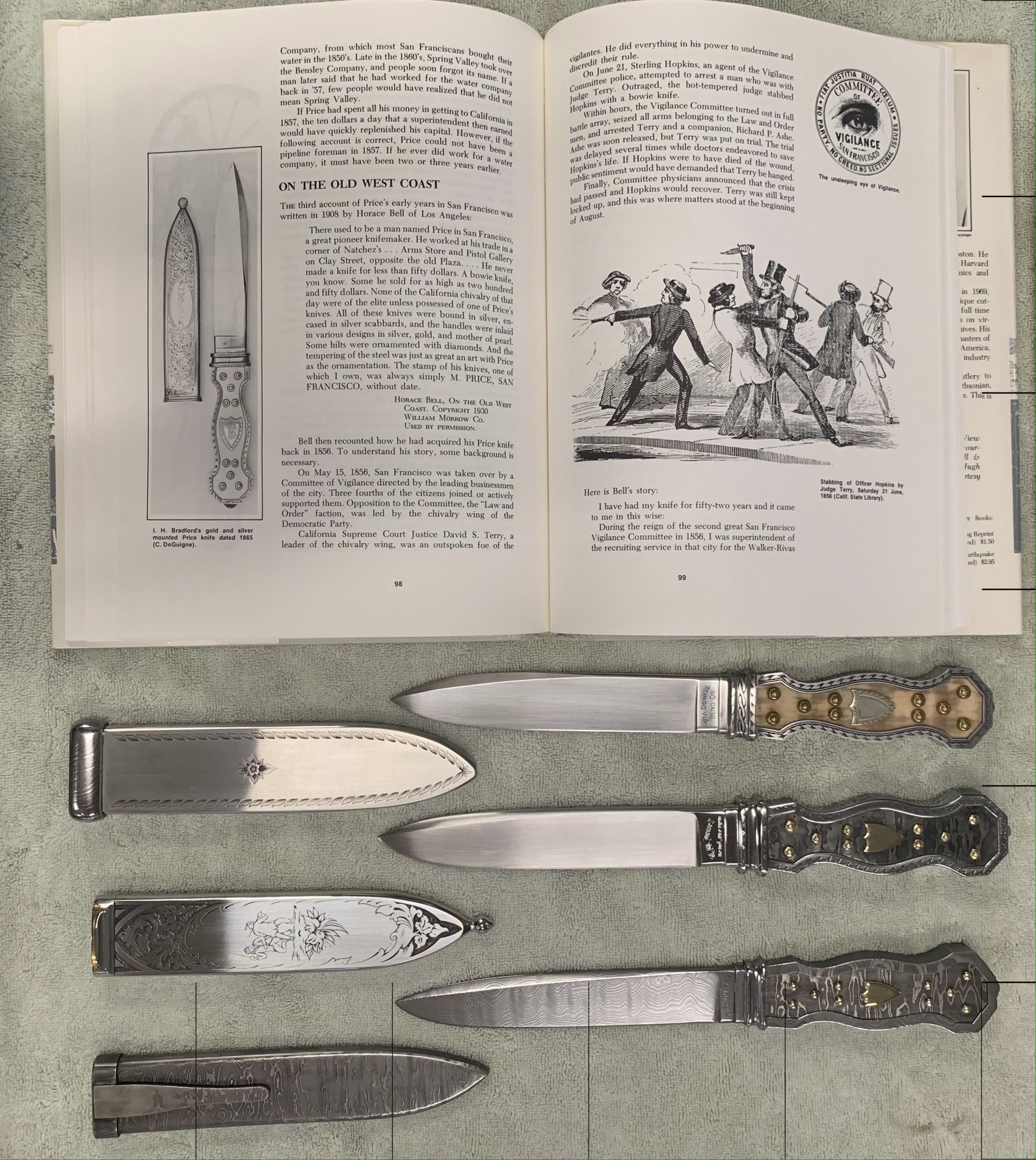

I'm planning a San Francisco style dagger or three in the relatively near future, but since I've never really seen one in person I have some questions about the construction.

Specifically:

-Is the guard typically one piece, or is it fabricated out of several pieces, or is it stacked out of several? Could go at it any of those ways, but I'd like to know what the originals were like. I intend to use sterling silver, if that matters.

-Similarly, on the Bradford dagger and some others, there's those large domed pins that look like they're 2 parts, and end up looking like a donut with a donut hole stuck on top. Again, not having seen one in person, none of the ways I can figure out to re-create the look make a lot of sense in historical context.

--And finally, the metal wraparound frame. Is this formed over a mandrel, fabricated from several pieces of silver via soldering, or what?

I realize this is a pretty obscure topic, but I'd like to pick the brain of some folks who have made these, or who have examined them up close. I can look at hi-res photos all day long, and I have the Bernard Levine book on the subject, but there's some questions only in-person examination can answer. I'm a pretty competent silversmith, so a lot of soldering doesn't scare me. I'm not necessarily committed to historically accurate construction either, but would like to at least be able to deviate from history with intent.

Thanks!

I'm planning a San Francisco style dagger or three in the relatively near future, but since I've never really seen one in person I have some questions about the construction.

Specifically:

-Is the guard typically one piece, or is it fabricated out of several pieces, or is it stacked out of several? Could go at it any of those ways, but I'd like to know what the originals were like. I intend to use sterling silver, if that matters.

-Similarly, on the Bradford dagger and some others, there's those large domed pins that look like they're 2 parts, and end up looking like a donut with a donut hole stuck on top. Again, not having seen one in person, none of the ways I can figure out to re-create the look make a lot of sense in historical context.

--And finally, the metal wraparound frame. Is this formed over a mandrel, fabricated from several pieces of silver via soldering, or what?

I realize this is a pretty obscure topic, but I'd like to pick the brain of some folks who have made these, or who have examined them up close. I can look at hi-res photos all day long, and I have the Bernard Levine book on the subject, but there's some questions only in-person examination can answer. I'm a pretty competent silversmith, so a lot of soldering doesn't scare me. I'm not necessarily committed to historically accurate construction either, but would like to at least be able to deviate from history with intent.

Thanks!