-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Miscellaneous

- Thread starter Poez

- Start date

Another one with Enzo AUS 8 blade (do not remember the name, I am not sure if they still manufacture/sell them) and some figured maple handle with a walnut stripe. The same stock sheath.

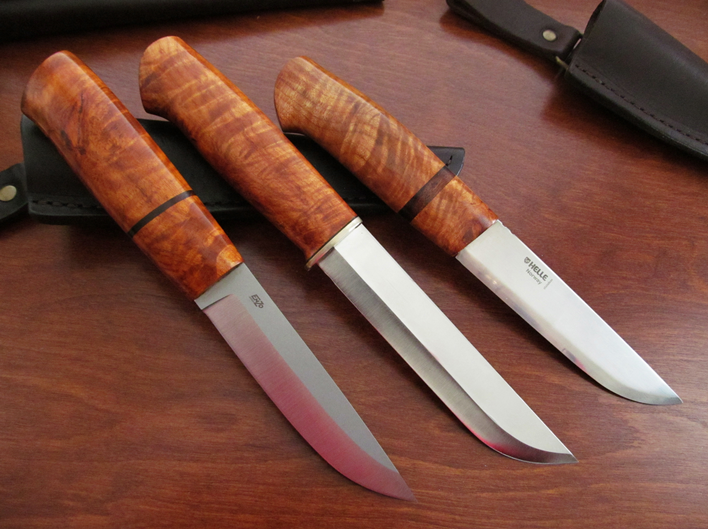

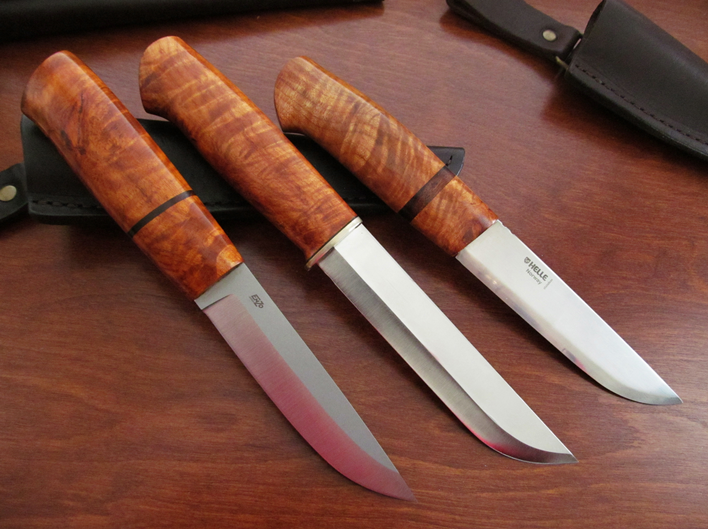

And here is a Scandi group photo, all made with the same piece of wood:

And here is a Scandi group photo, all made with the same piece of wood:

- Joined

- Jan 15, 2001

- Messages

- 4,053

nice jobs all the way round! In the photo of the three Scandis, what is the middle blade? John

Thanks John! The middle one is Lauri Camping like in the link: http://brisa.fi/knife-blades/lauri-stainless/lauri-camping-145.htmlnice jobs all the way round! In the photo of the three Scandis, what is the middle blade? John

Keep on going through the stock of blades that I have accumulated over the years. Not sure about the wood that I've used for the handles on these two: it is either some species of walnut or some red wood, don't remember. Pretty tough and hard to work with that's for sure, on par with bubinga.

Hi, thanks for kind words. This is the Kanetsune blade that I've used: http://www.knifeworks.com/kanetsune9takumi-yariknife.aspx#.V7FKriseoo0 It was very "strange" originally so I had to do some tweaking: it ended up as sort of "half-full tang/half-hidden tang" with the handle comprised of four pieces of wood to straighten it up. Thankfully cocobolo is quite forgiving when hiding the seams. Do not have any WIP pictures but can draw you one if you are interested. Good luck with scandis, share the result!Love you work! I'm currently sitting on a stash of scandis I got from Brisa as well. Gotta ask, where did you find the kanetsune blade?

Thanks for link! I think I have a good idea of how you got to to work  . I have a running thread with a few of my knives here. http://www.bladeforums.com/forums/showthread.php/1418212-My-Works

. I have a running thread with a few of my knives here. http://www.bladeforums.com/forums/showthread.php/1418212-My-Works

I'm finishing up the sheath on another this week so I'll be adding more next week. If your looking for unique style Scandi I really recommend mikael eklund. He has some really cool stuff!

I'm finishing up the sheath on another this week so I'll be adding more next week. If your looking for unique style Scandi I really recommend mikael eklund. He has some really cool stuff!

So here is another one with a tool steel blade, bronze bolster and zebrano handle. One less blade and one more knife in my collection. And here goes the last stock sheath that I've got.

I hope you like it. I do not like the traditional scandi handle shape that usually goes with that type of blade, so that was a learning opportunity for me.

I hope you like it. I do not like the traditional scandi handle shape that usually goes with that type of blade, so that was a learning opportunity for me.

- Joined

- Jul 2, 2012

- Messages

- 274

Really nice looking blades. I especially love the fourth one!!!!

Another great one. What kind of finish are you using CCL knife oil?

Thanks! I looked up CCL knife oil: it looks a bit expensive to me. I use a different technique that serves me well enough. First of all I sand the wood up to 600 grit (I did it up to 2000 in the past but it is not really necessary in my opinion), then I polish it by hand along the grain using some polishing paste for soft metals (the brown one). After that I first soak (literally) the handle for some time in a mineral oil (something non-polymerizing and well penetrating. I guess it would be similar to Ikea's Skydd: or whatever butcher block oil you can find. The soaking time will essentially depend on the wood but I would recommend moderation as with time the grain may become darker and less contrasting). Then I wipe it dry as much as I can with a paper towel and seal with a couple of coats of polymerizing oil, like Danish Oil. Then finally after it all dries completely protect it with a couple of coats of wipe on polyurethane. In the past I used shellac for the final coat but then decided to go for wipe on poly for better water protection. So now I have to be more particular about polymerizing oil seal as poly is a bit more tricky. Anyway, if you decide to give it a try do it first on some left-over piece of wood to make sure the combination works.

Have finished another one yesterday. It took me extra time mostly due to some re-work on the blade shape, grind and finish. That Swedish carbon steel was pretty tough to grind and rub but it was worth it. So here it goes: a forged blade I've bought a few years back, bronze guard and walnut handle, sheath.

Last edited:

I've shared these pictures earlier in Traditional section:

And now since I came to like the result, the size and the grind I decided to spend time and add a proper sheath. Now it's complete.

I am still learning. For example I will not use that particular thread on a sheath again, at least not in a place where it will be seen. But otherwise it does not look too bad.

And now since I came to like the result, the size and the grind I decided to spend time and add a proper sheath. Now it's complete.

I am still learning. For example I will not use that particular thread on a sheath again, at least not in a place where it will be seen. But otherwise it does not look too bad.

- Joined

- Jan 15, 2001

- Messages

- 4,053

The swedish blade with the walnut handle came out very nice. Any idea on the name of the blade maker? As far as the thread on the last sheath, looks like it compliments the rough character of the knife just right. John

The name of the blacksmith is Vladimir Grigoriev. I bought that blade something like 7 years ago. Finally the day came. I used his blades for knives in post #1 and #16 of this thread.The swedish blade with the walnut handle came out very nice. Any idea on the name of the blade maker? As far as the thread on the last sheath, looks like it compliments the rough character of the knife just right. John

Used a blade from Ontario Knife SP46 Boar Skinner. I like carbon steel, believe it looks better in patina than in that "tactical" black coating. Used bubinga for the handle: it is very good wood for tools, handles and everything but it is a pain to shape.

Need to experiment more on the pommel and do more tweaking on the blade in the ricasso area next time.

Need to experiment more on the pommel and do more tweaking on the blade in the ricasso area next time.