rrrgcy

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 21, 2005

- Messages

- 105

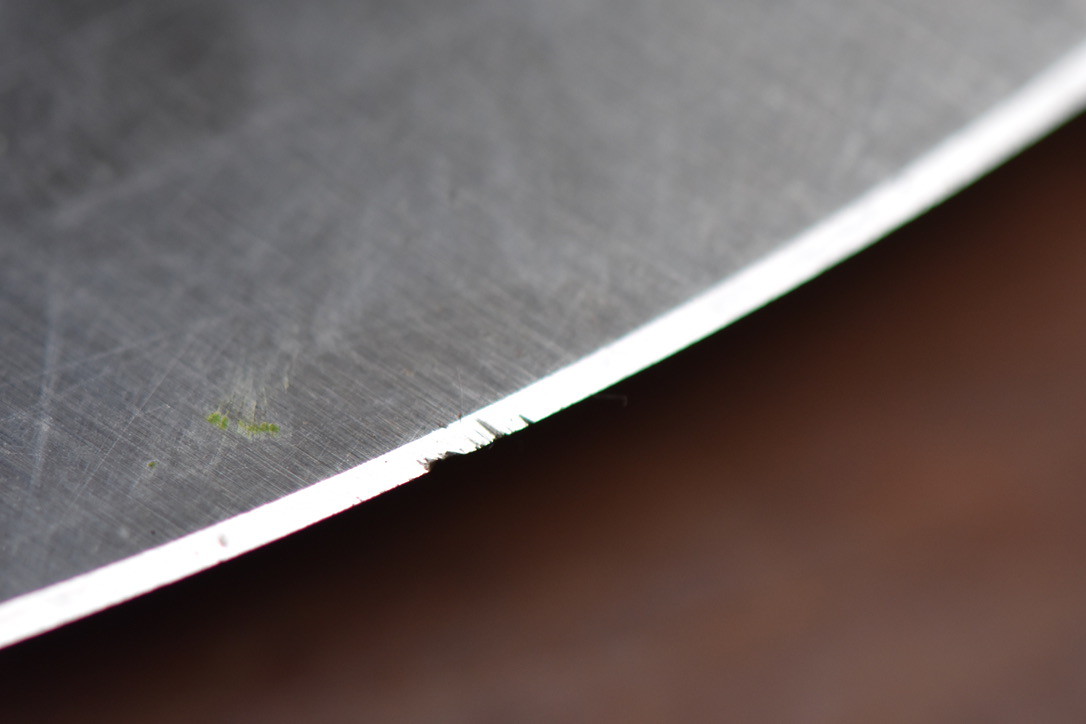

As a novice to axes (well, BSA excepted) and acquiring several contemporary new from the majors I now also have several from some of our small US forgers. I test each the same on arrival - perhaps unfair but it’s consistent - to working the front lawn roots uniformly (no pebbles, rocks, some embedded sand, though I’m really hitting mostly wood which root seems clean). The axes handle the task with ease and no harm. A recent acquisition of a model from a small forge resulted in good edge damage (see imaging). I checked the hardness and was surprised the edge was low-40’s Rc, not even 45Rc. Behind the edge 1/2” was below 40Rc. I’m guessing this missed heat treatment or was done wrong. The seller stood up to a return but I reprofiled the heaviness behind the edge and re-heat treated it (a little high) to around 60Rc and behind 1/2” around 55Rc and less away.

I’m not going to identify the maker, a couple other different products from him came with edge hardness of 60Rc, so this might have been a sole error. But it makes one lose faith that any within that model are properly hard. Last image is of my post heat treat and a 5” dia root easily worked without harm. Unsure how uncommon is a miss but I think it wise to test intended user’s edges.

I’m not going to identify the maker, a couple other different products from him came with edge hardness of 60Rc, so this might have been a sole error. But it makes one lose faith that any within that model are properly hard. Last image is of my post heat treat and a 5” dia root easily worked without harm. Unsure how uncommon is a miss but I think it wise to test intended user’s edges.

Attachments

Last edited: