- Joined

- Jul 3, 2023

- Messages

- 5

Hey All,

This is my first post. I just caught knife fever last year and now I can't stop buying them, but I've still got a lot to learn about different steels.

I bought a MKM Makro 2 in M390, which is a steel many people I've talked to absolutely love. That said, the heat treat must be TERRIBLE because it's the softest knife steel I own. Even worse than crappy knives with Chinese steel from I bought online. It was almost... gummy...when trying to raise a bur and then remove it. Not sure that's the right word, but the chances of this edge chipping instead of rolling over are about zero.

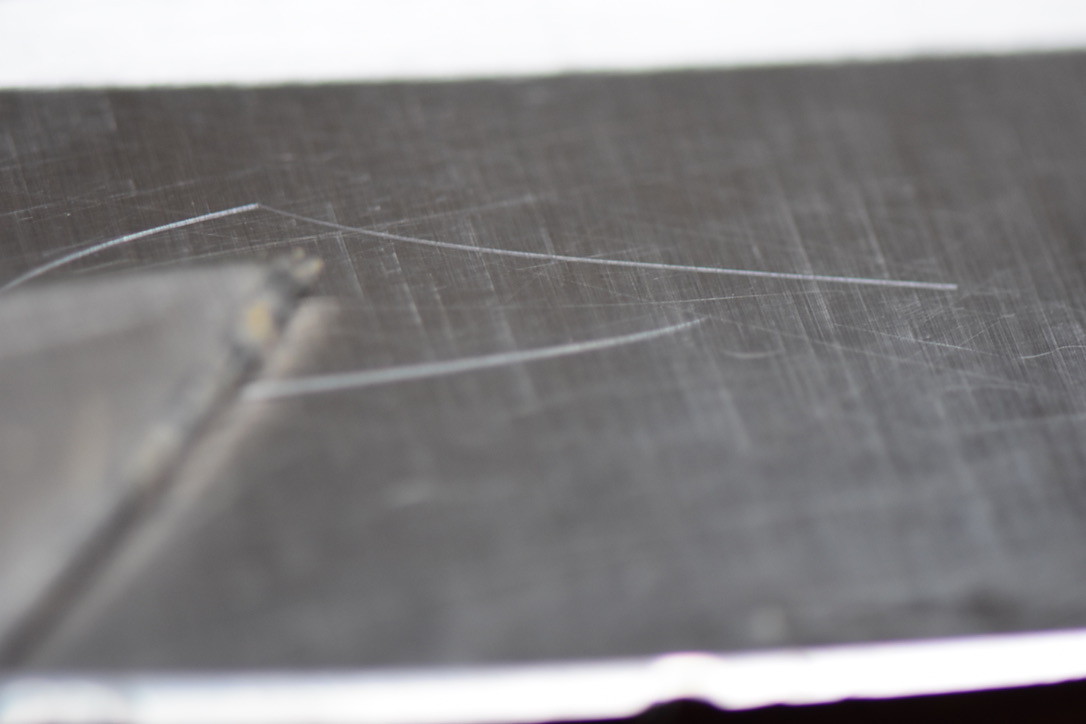

So, now I have these beautiful fat carbon scales on a knife that's barely useable. I took them off and want to repurpose them for SOMETHING, but have no idea what and no experience trying to mess with the shape/profile of fat carbon scales so they fit a handle on a different knife. Any ideas or suggestions?

Thanks, Nate

[link to non-supporting dealer removed.]

This is my first post. I just caught knife fever last year and now I can't stop buying them, but I've still got a lot to learn about different steels.

I bought a MKM Makro 2 in M390, which is a steel many people I've talked to absolutely love. That said, the heat treat must be TERRIBLE because it's the softest knife steel I own. Even worse than crappy knives with Chinese steel from I bought online. It was almost... gummy...when trying to raise a bur and then remove it. Not sure that's the right word, but the chances of this edge chipping instead of rolling over are about zero.

So, now I have these beautiful fat carbon scales on a knife that's barely useable. I took them off and want to repurpose them for SOMETHING, but have no idea what and no experience trying to mess with the shape/profile of fat carbon scales so they fit a handle on a different knife. Any ideas or suggestions?

Thanks, Nate

[link to non-supporting dealer removed.]

Last edited by a moderator: