- Joined

- Jun 6, 2014

- Messages

- 683

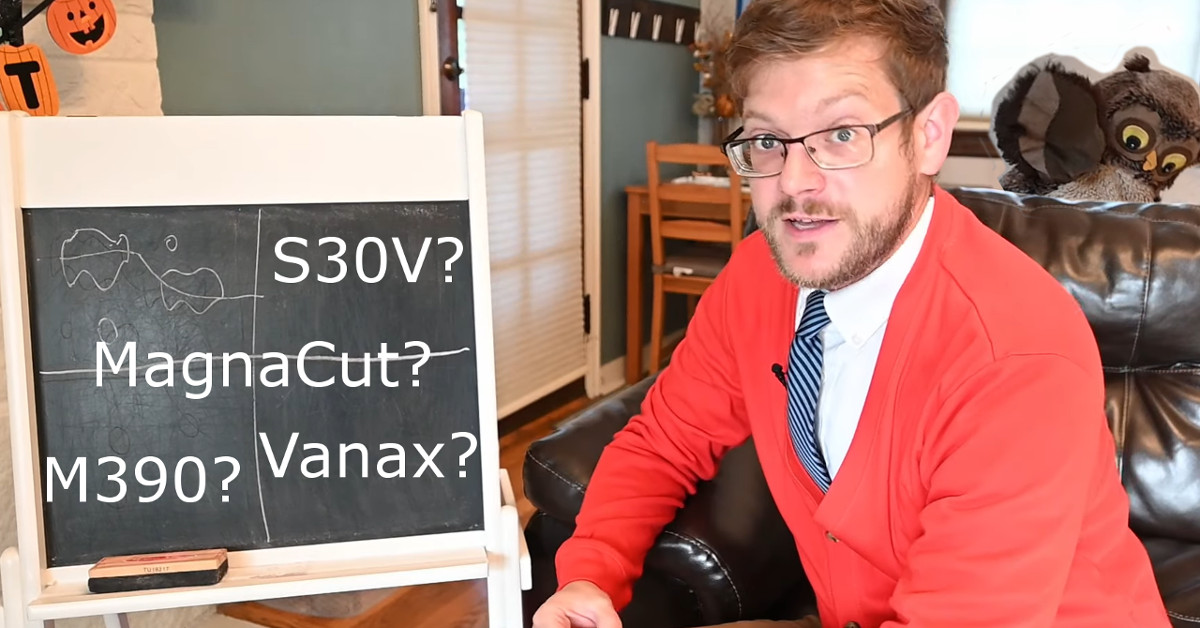

I really do like my Spyderco endura, but I'm not so sure how I feel about VG10 steel. I feel like it requires a touch up more often than I like to have to do to keep it receipt paper slicing sharp. For example, I was cutting a lemon and hit a seed, backed off and didn't even cut through it but afterward had to touch it up on a ceramic rod to be able to slice thin paper again. Is this to be expected for VG10? Would super steels also require this much attention? I'm thinking K390 or zdp189 would probably hold a fine edge like this better but something like a lemon would give a patina in no time I presume, and I just can't get behind that look for a blade. Thoughts?