-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Search for the Magic Heat Treatment

- Thread starter Larrin

- Start date

Larrin

Gold Member

- Joined

- Jan 17, 2004

- Messages

- 5,039

After visiting a couple knife shows, I was confused and intrigued by knifemakers who would promote their superior heat treatment or steel selection. Who was telling the truth about his knives? Who was sharing real science and who was just selling knives? I started reading everything I could about metallurgy. I went to school to learn Materials Science. I designed heat treatments for steels with my dad and thought up testing methods for measuring performance. I now work for a steel company designing alloys and heat treatments for the automotive steel market. Unlike tool steel companies, these steels are not heat treated by the final customer, so both the alloy and heat treatment design is done by development engineers for this market. That means we get to see quite intimately the interplay between alloy design and heat treatment. How the heat treatments can be manipulated for different properties and how the alloy can be manipulated to get better results out of the heat treatment. It's a design loop, both feeding the other.

It is popular among knifemakers to say that getting a good heat treatment is more important than the right steel. There is some truth to this. It's easy to go down a rabbit hole of the seemingly unlimited number of steel choices until you are paralyzed by choice. And learning how to heat treat one steel correctly is much better than heat treating 20 different steels poorly. However, you can go too far with this idea. A steel that is high in carbide volume and therefore limited by toughness will never reach the level of toughness that S7 can achieve. Any given steel can be heat treated to a range of properties, but part of steel selection is realizing when a given steel isn't right for the application.

And yet, the draw of "perfecting" the heat treatment is always there, gnawing at the back of my mind. Can I get another 10% out of this steel? In grad school our steel research center gets their research topics from industrial companies who pay for the research. When I started talking to my advisor about my interests and what types of thesis topics would be good for me, my advisor said, "Picking a thesis topic will be easy. Everything you've talked about is related to heat treating. I have just the study for you." Engineers are not immune from the draw of the perfect heat treatment. Scientific journals are full of multiple quenching studies and different cryogenic processing procedures just like knifemakers are talking about. Rarely does any heat treatment change the whole world of steel. We are normally looking for small improvements over standard practices. A 10% increase in a property can be considered a success. But that doesn't stop the pursuit.

So what have I learned since I visited my first knife show at 16? Were the knifemakers telling the truth? Did they really have secret steels and special unknown heat treatments? In some cases yes, in many cases no. A lot of the time the knifemakers were simply misinformed, some were just trying to sell and hardly cared about the accuracy of their statements at all. Many hold to their beliefs like religion, unable to believe that they may be wrong about their prized heat treatment or the "metallurgy" they are spouting. Most are performing heat treatments that are just fine, but the rationale behind certain steps is likely erroneous and they are doing things in convoluted or unnecessary ways. I've been unimpressed in general with test methods by knifemakers. There are very few controls in place and I don't put much stock in qualitative, inconsistent tests with multiple variables being changed between knife: geometry, steel, hardness, etc. It doesn't mean the knives are bad, but their testing may be telling them less than they think. If good testing was being performed, the unnecessary steps and erroneous ideas would naturally fall away a little more often.

I know that a good knife is more than the steel. I know that a good knife can be made out of a lot of steels with a lot of different heat treatments. But I felt the draw of metallurgy and heat treating. I know that the secret, ultra mega steel isn't really out there. And the special triple-loop deluxe heat treatment doesn't exist. But I will continue to search for it anyway.

It is popular among knifemakers to say that getting a good heat treatment is more important than the right steel. There is some truth to this. It's easy to go down a rabbit hole of the seemingly unlimited number of steel choices until you are paralyzed by choice. And learning how to heat treat one steel correctly is much better than heat treating 20 different steels poorly. However, you can go too far with this idea. A steel that is high in carbide volume and therefore limited by toughness will never reach the level of toughness that S7 can achieve. Any given steel can be heat treated to a range of properties, but part of steel selection is realizing when a given steel isn't right for the application.

And yet, the draw of "perfecting" the heat treatment is always there, gnawing at the back of my mind. Can I get another 10% out of this steel? In grad school our steel research center gets their research topics from industrial companies who pay for the research. When I started talking to my advisor about my interests and what types of thesis topics would be good for me, my advisor said, "Picking a thesis topic will be easy. Everything you've talked about is related to heat treating. I have just the study for you." Engineers are not immune from the draw of the perfect heat treatment. Scientific journals are full of multiple quenching studies and different cryogenic processing procedures just like knifemakers are talking about. Rarely does any heat treatment change the whole world of steel. We are normally looking for small improvements over standard practices. A 10% increase in a property can be considered a success. But that doesn't stop the pursuit.

So what have I learned since I visited my first knife show at 16? Were the knifemakers telling the truth? Did they really have secret steels and special unknown heat treatments? In some cases yes, in many cases no. A lot of the time the knifemakers were simply misinformed, some were just trying to sell and hardly cared about the accuracy of their statements at all. Many hold to their beliefs like religion, unable to believe that they may be wrong about their prized heat treatment or the "metallurgy" they are spouting. Most are performing heat treatments that are just fine, but the rationale behind certain steps is likely erroneous and they are doing things in convoluted or unnecessary ways. I've been unimpressed in general with test methods by knifemakers. There are very few controls in place and I don't put much stock in qualitative, inconsistent tests with multiple variables being changed between knife: geometry, steel, hardness, etc. It doesn't mean the knives are bad, but their testing may be telling them less than they think. If good testing was being performed, the unnecessary steps and erroneous ideas would naturally fall away a little more often.

I know that a good knife is more than the steel. I know that a good knife can be made out of a lot of steels with a lot of different heat treatments. But I felt the draw of metallurgy and heat treating. I know that the secret, ultra mega steel isn't really out there. And the special triple-loop deluxe heat treatment doesn't exist. But I will continue to search for it anyway.

Last edited:

- Joined

- Nov 27, 2002

- Messages

- 2,087

Excellent search......and with your background, a lot more can be learned...

- Joined

- Jul 27, 2003

- Messages

- 5,686

In my first or second year of knife making - '96-'97 - I was told by seasoned knife maker, Jerry Rados, "Jesus Christ, Himself, can send a bar of steel down from Heaven. It will only be as good as the heat treatment it gets on Earth".

No - there is no "secret, ultra mega steel", and the "special triple-loop deluxe heat treatment doesn't exist" statement is true.

I also really liked your statement, "Most are performing heat treatments that are just fine, but the rationale behind certain steps is likely erroneous and they are doing things in convoluted or unnecessary ways." This is the result of lacking understanding of the BASICS of heat treating. Most of which are posted above in the stickys.

Might I also add that I really did appreciate your clarity, grammar and accurate sentence structure in your description.

It's nice to not have to decipher and translate what I was attempting to read. A real relief from the illiterate and often nearly impossible diatribe on these pages. . :thumbup:

Other than that, as long as a maker educates him/herself on the heat treating basics and strives to always get just a little better on each knife, then progress will be made.

Consumers, as well, can help us overall by engaging us in conversations about our processes.

I wonder if more consumers care about their knives' treatments than the makers? Hard to say.

Wonderful conversation.

No - there is no "secret, ultra mega steel", and the "special triple-loop deluxe heat treatment doesn't exist" statement is true.

I also really liked your statement, "Most are performing heat treatments that are just fine, but the rationale behind certain steps is likely erroneous and they are doing things in convoluted or unnecessary ways." This is the result of lacking understanding of the BASICS of heat treating. Most of which are posted above in the stickys.

Might I also add that I really did appreciate your clarity, grammar and accurate sentence structure in your description.

It's nice to not have to decipher and translate what I was attempting to read. A real relief from the illiterate and often nearly impossible diatribe on these pages. . :thumbup:

Other than that, as long as a maker educates him/herself on the heat treating basics and strives to always get just a little better on each knife, then progress will be made.

Consumers, as well, can help us overall by engaging us in conversations about our processes.

I wonder if more consumers care about their knives' treatments than the makers? Hard to say.

Wonderful conversation.

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,257

Thank you Larrin -I fully agree.

I just wish people would understand that all the secrets and special treatments are only good if they are metallurgically sound. People who say they have found new "unknown" procedures and are getting un-scientific results are just modern age witch doctors and snake oil salesmen.

1084 HT that gets Rc68, AEBL blades at Rc65, and twisting the structure in steel crystals to get much harder steel is not going to happen on this planet.

Good HT procedures and careful testing of your HT results will get a good knife every time.

I just wish people would understand that all the secrets and special treatments are only good if they are metallurgically sound. People who say they have found new "unknown" procedures and are getting un-scientific results are just modern age witch doctors and snake oil salesmen.

1084 HT that gets Rc68, AEBL blades at Rc65, and twisting the structure in steel crystals to get much harder steel is not going to happen on this planet.

Good HT procedures and careful testing of your HT results will get a good knife every time.

- Joined

- Jun 10, 2003

- Messages

- 15,288

Don't try to separate HT and alloying ! They will always be connected. Take 9260 a common auto suspension steel .In our world of micro-alloying a pinch of vanadium was added and the resulting spring was stronger and weight reduced by 15% ! In the knife world Cryogenics can add a bit more strength in the more complex alloys . Many still don't understand cryo but going to the basics it's all there .Again in the auto world a number of interesting alloys have been made .HT'd in the mill then formed and welded later With no detriment to performance .And these same alloys increase toughness - the crashability that saves lives !

Get a good understanding in the basics .That's your foundation , and go from there.

Get a good understanding in the basics .That's your foundation , and go from there.

- Joined

- Feb 21, 2007

- Messages

- 270

Larrin...I enjoyed reading your post, but it left me wanting for more. You've identified issues within the knife community in regards to HT and I fully agree with what you've stated. Where is a newb like me to turn for accurate information? Are there books written for the layman that you could recommend? I've believe I've learned much from reading in this forum, and as with any online reference, the wheat needs to be separated from the chaff. If you could point out a good resource or two, it would be very much appreciated.

Larrin

Gold Member

- Joined

- Jan 17, 2004

- Messages

- 5,039

https://www.amazon.com/Steels-Processing-Performance-George-Krauss/dp/0871708175Larrin...I enjoyed reading your post, but it left me wanting for more. You've identified issues within the knife community in regards to HT and I fully agree with what you've stated. Where is a newb like me to turn for accurate information? Are there books written for the layman that you could recommend? I've believe I've learned much from reading in this forum, and as with any online reference, the wheat needs to be separated from the chaff. If you could point out a good resource or two, it would be very much appreciated.

https://www.amazon.com/Steel-Metall...86&sr=1-1&keywords=Verhoeven+steel+metallurgy

https://www.amazon.com/Tool-Steels-...F8&qid=1468414226&sr=1-1&keywords=tool+steels

The Verhoeven book is really good and starts from the basics very well. The tool steels book is a treasure trove of old research on tool steels. The 4th edition is much larger than the 5th but there are a few things unique to the 5th. The Krauss book covers a lot of information on different types of steels and the various mechanisms, transformations, etc.

Heat treating takes practice. The more you do the better you get. Your furnace or forge, the steel type, size of blade, quench speed, straightening, tempering, sub-zero quenching, etc. all vary. You'll make lots of mistakes if you think you just heat it up and quench it.

Make lots of test coupons, test the hardness and then brake them. I've been heat treating for almost 40 years and do more testing than ever.

Hoss

Make lots of test coupons, test the hardness and then brake them. I've been heat treating for almost 40 years and do more testing than ever.

Hoss

Matthew Gregory

Chief Executive in charge of Entertainment

- Joined

- Jan 12, 2005

- Messages

- 6,528

I appreciate the positions here, and I understand and agree with the vast majority of it. By your own admission, though, Larrin, metallurgy is a young science, and scientists and engineers, just like EVERYONE ELSE, are notorious for achieving a stasis and latching ahold of what's 'known', 'acceptable', 'comfortable'. I've encountered this myself.

The fact is that there is a lot we don't understand. Unorthodox thinking is the cornerstone of science. However, it ABSOLUTELY MUST be tempered with the fundamentals of scientific principle, and that's, of course, what you're pointing to, here. I think it's important to try to keep an open mind, and not necessarily dismiss an 'outlier' viewpoint, but it is critical to insist that such a viewpoint be tested. TESTED. Not anecdotally, not continuing to apply bizarre theory to support the results, but TESTING. Minimization of variables, locking down of controls and process, opening the procedures to peers for additional experiences. It's about coming up with a concept, then proving that concept wrong. If you can't, then it's very possible that your concept holds merit.

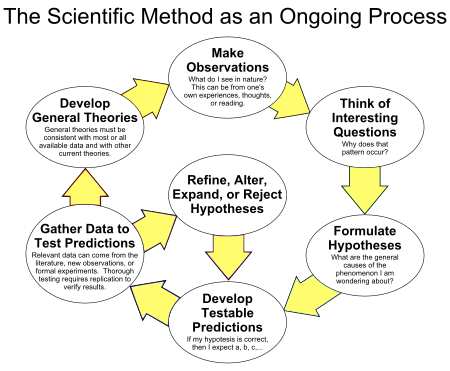

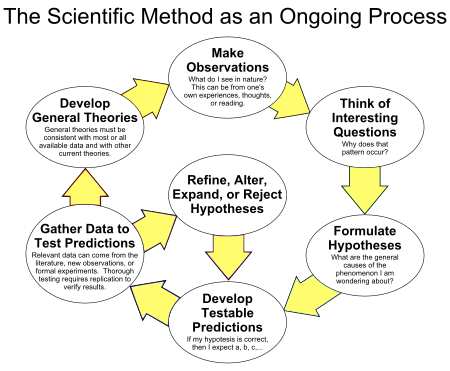

Cobbed directly from Wikipedia, because it's just too elegant of a graphical depiction:

If a person wants to do it their way, swell. That's dandy! It's important for an individual to be true unto oneself. Just don't get upset when others shake their heads at your bullshit!

The fact is that there is a lot we don't understand. Unorthodox thinking is the cornerstone of science. However, it ABSOLUTELY MUST be tempered with the fundamentals of scientific principle, and that's, of course, what you're pointing to, here. I think it's important to try to keep an open mind, and not necessarily dismiss an 'outlier' viewpoint, but it is critical to insist that such a viewpoint be tested. TESTED. Not anecdotally, not continuing to apply bizarre theory to support the results, but TESTING. Minimization of variables, locking down of controls and process, opening the procedures to peers for additional experiences. It's about coming up with a concept, then proving that concept wrong. If you can't, then it's very possible that your concept holds merit.

Cobbed directly from Wikipedia, because it's just too elegant of a graphical depiction:

If a person wants to do it their way, swell. That's dandy! It's important for an individual to be true unto oneself. Just don't get upset when others shake their heads at your bullshit!

- Joined

- Feb 21, 2007

- Messages

- 270

Your points on the scientific method are valid Matthew. And there is an all important part of that process that merits repeating. Peer review, repeatability, and experiment duplication. I think this is where some knife makers fall short when making claims of "magical heat treat processes". If a claim is true and has merit, then it should be repeatable by others. If someone is unwilling to share the specific process, then that process will forever remain questionable, met with skepticism and perhaps even viewed as bogus. True that we should always keep an open mind about things, but until I repeat an experiment for myself, it can only be viewed as hypothetical. This is the way it works.

- Joined

- Jul 13, 2009

- Messages

- 21,536

In my first or second year of knife making - '96-'97 - I was told by seasoned knife maker, Jerry Rados,

"Jesus Christ, Himself, can send a bar of steel down from Heaven. It will only be as good as the heat treatment it gets on Earth".

.

And the discussion about decarb formed on re-entry would be a never ending one too.

- Joined

- Feb 21, 2007

- Messages

- 270

I certainly never stated that claims should be not be tested.

Quite the contrary Larrin...I felt your original post advocated for proven methods that were repeatable.

Matthew Gregory

Chief Executive in charge of Entertainment

- Joined

- Jan 12, 2005

- Messages

- 6,528

Quite the contrary Larrin...I felt your original post advocated for proven methods that were repeatable.

Yeah, thought so too!!!

Hope you didn't translate my post any other way. Not my intention at all!!!

- Joined

- Nov 10, 2011

- Messages

- 1,125

good thread. I think Larrin that the perfect heat treat does not exist. that said, if you approach steel heat treat as a problem with multiple variables and eliminate as many variables as possible, you have a repeatable process with repeatable results. if you keep the process simple, you get good results. for the newbies reading, here is list:

a heat source that can maintain temperatures +/-25 degrees F. (heat treat furnace, glass kiln, pottery kiln, lab furnace doesn't matter so long as it can heat to necessary hardening temperature.

a good thermocouple and display so you can monitor temperature. extra nice would be a second thermocouple that sits right next to the blade.

a known quenchant heated to recommended temperature.

a second heat source that can heat to tempering temperatures.

scott

a heat source that can maintain temperatures +/-25 degrees F. (heat treat furnace, glass kiln, pottery kiln, lab furnace doesn't matter so long as it can heat to necessary hardening temperature.

a good thermocouple and display so you can monitor temperature. extra nice would be a second thermocouple that sits right next to the blade.

a known quenchant heated to recommended temperature.

a second heat source that can heat to tempering temperatures.

scott

- Joined

- Nov 10, 2011

- Messages

- 1,125

I work with Aldo's1084, AlphaKnife 80CrV2, O1, O2, and 1.2519. I use 800C(1480F) as my temperature. heat the kiln to 800C. add knife. when kiln is back to 800C start timing. for 1/8" O2, 1084 and 80CrV2 5 minutes. for 1/16" 1.2519 8 minutes. for 1/32" or 3/64" O1 7 minutes. 1/16 and 3/32 O1 10 minutes. 1/8" 15 minutes, 5/32 18 minutes. quench in 10-12 second oil until you can touch. wipe off oil then rinse in cold tap water. temper at 300F for an hour. put in cold soapy water and scrub off any scale. rinse in cold water. temper for final hardness. I make kitchen knives of O1 and 1.2519 and usually second temper at 325-350F yields Rc63-64

keep a log book and write down exactly what you did with each blade. find someone with a calibrated hardness tester and check your work.

use known steel. I use Starrett O1 ground flat stock because i know that company spends millions each year on quality assurance and that each piece of their steel will heat treat just like the last.

hope this is helpful.

scott

keep a log book and write down exactly what you did with each blade. find someone with a calibrated hardness tester and check your work.

use known steel. I use Starrett O1 ground flat stock because i know that company spends millions each year on quality assurance and that each piece of their steel will heat treat just like the last.

hope this is helpful.

scott