- Joined

- Feb 15, 2010

- Messages

- 696

This smiling razor will be done in W2 for the purpose of pulling a cloudy hamon. I've made other 8/8 but have not attempted to do differential hardening on them; this is definitely a first. The design is modeled after an older Wade and Butcher that caught my eye a while ago but was WAY outside of my razor budget. The blade will also be hollow ground on a 72" radiused platen for just a slight hollow that is nearly flat.

As always, any and all criticism and tips are welcome.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

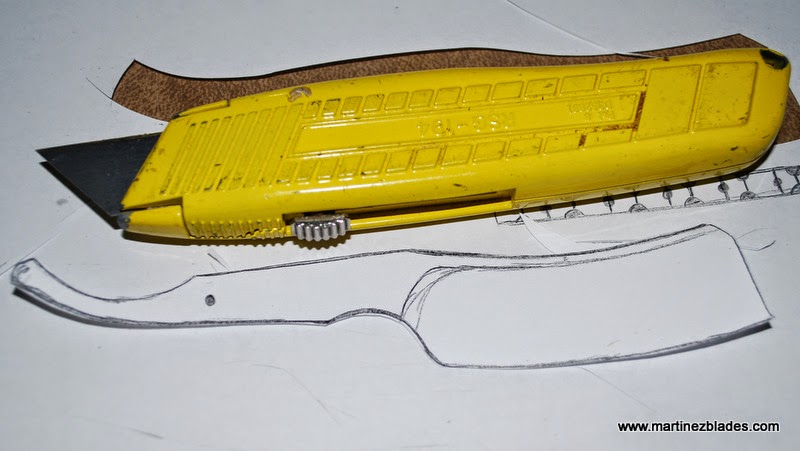

Cutting the paper pattern out from a photocopy of the original

The pattern is adhered to the steel billet with spray adhesive

For the sake of redundancy the pattern is scratched into the steel with a carbide scribe and repeated with a black permanent marker

As always, any and all criticism and tips are welcome.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Cutting the paper pattern out from a photocopy of the original

The pattern is adhered to the steel billet with spray adhesive

For the sake of redundancy the pattern is scratched into the steel with a carbide scribe and repeated with a black permanent marker

Last edited: