Sean Yaw

Gold Member

- Joined

- Feb 26, 2019

- Messages

- 418

Hi,

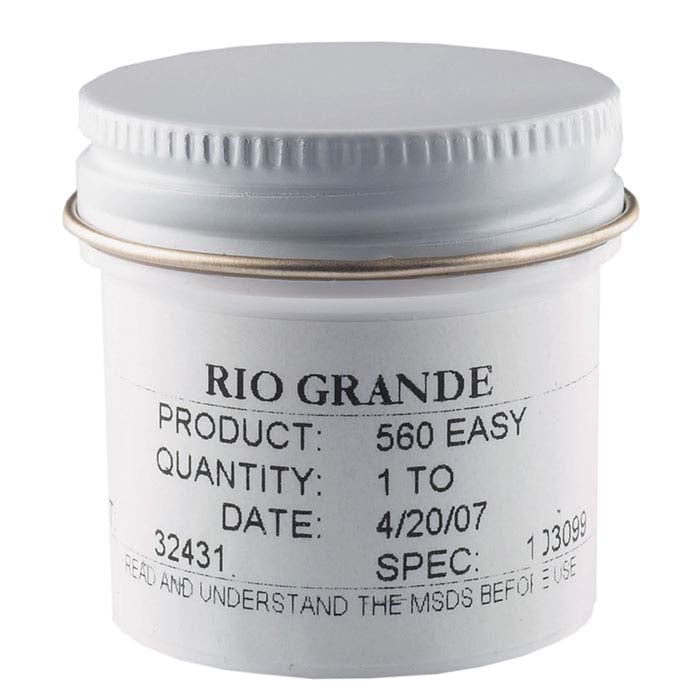

I have been making slipjoints and lockbacks for several months now and would like to pursue attaching pins to the back of my shields (as opposed to just gluing or drilling through) as well as attaching bolsters. It sounds like soldering or brazing may be a good way to approach both of these tasks. My question is: What equipment is recommended for accomplishing this. I have gathered that I need a torch instead of electrical iron due to the temperatures required. Does anyone have a recommendation for a good torch that will serve me well for a little while? I have also read about using all-in-one solder/flux for attaching pins such as this product:

www.riogrande.com

Is that approach recommended, or something different? Are there any other tools/supplies I will need? I am sure a lot of this will come down to practice/experimentation, but I am trying to avoid buying something (e.g. torch) only to find out I got the wrong thing. Thank you for the advice.

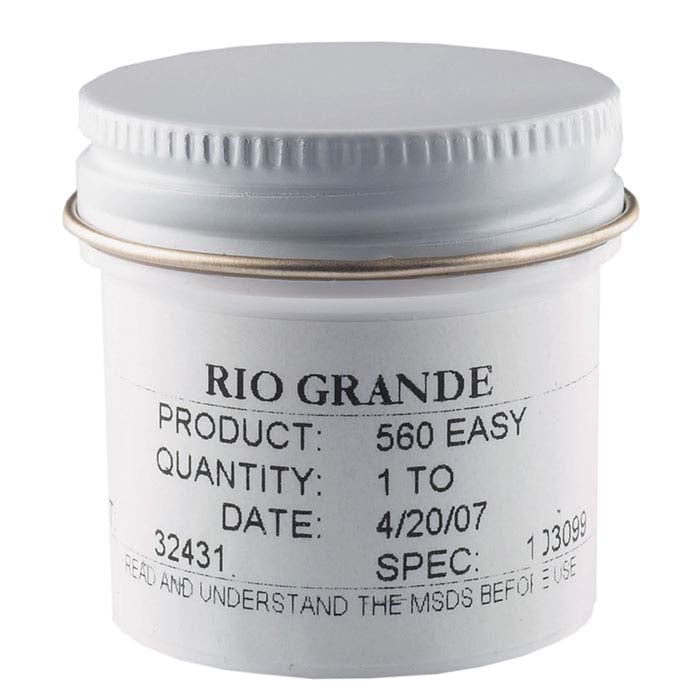

www.riogrande.com

Is that approach recommended, or something different? Are there any other tools/supplies I will need? I am sure a lot of this will come down to practice/experimentation, but I am trying to avoid buying something (e.g. torch) only to find out I got the wrong thing. Thank you for the advice.

I have been making slipjoints and lockbacks for several months now and would like to pursue attaching pins to the back of my shields (as opposed to just gluing or drilling through) as well as attaching bolsters. It sounds like soldering or brazing may be a good way to approach both of these tasks. My question is: What equipment is recommended for accomplishing this. I have gathered that I need a torch instead of electrical iron due to the temperatures required. Does anyone have a recommendation for a good torch that will serve me well for a little while? I have also read about using all-in-one solder/flux for attaching pins such as this product: