PEU

Gaucho Knifemaker

- Joined

- Aug 6, 2006

- Messages

- 1,180

Hi guys, I'm a huge fan of Sandvik 14C28N, you can say its an improved version of AEB-L.

I use it for all my culinary knives in 2mm (0.08") thickness with great success.

BUT

It seems at one point Sandvik rolls the sheets and this tension is never relieved before shipping to the customers (its my theory), so after laser cutting a seemingly flat sheet all the knives end up with a noticeable warp.

To solve this, I thermal cycle them first to 850C and then heat to 600C and leave them overnight so they are soft again.

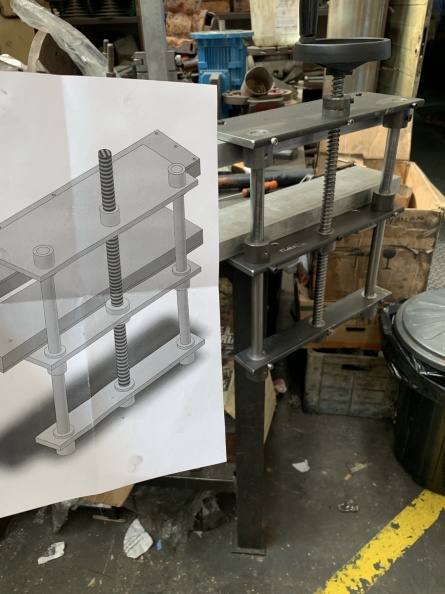

Then I do what I need to do, holes etc, and do the hardening/tempering using my watercooled hardening press, even with this pressure, I estimate around 50kg/100 pounds, some of them, around 10% still warp.

On the other hand, steels from Bohler, say K110 (D2) or K720 (O2) end up dead flat 99% of the time at the same thickness.

Is there something you guys suggest to improve my good shield using 14C28N?

Thanks

Pablo

I use it for all my culinary knives in 2mm (0.08") thickness with great success.

BUT

It seems at one point Sandvik rolls the sheets and this tension is never relieved before shipping to the customers (its my theory), so after laser cutting a seemingly flat sheet all the knives end up with a noticeable warp.

To solve this, I thermal cycle them first to 850C and then heat to 600C and leave them overnight so they are soft again.

Then I do what I need to do, holes etc, and do the hardening/tempering using my watercooled hardening press, even with this pressure, I estimate around 50kg/100 pounds, some of them, around 10% still warp.

On the other hand, steels from Bohler, say K110 (D2) or K720 (O2) end up dead flat 99% of the time at the same thickness.

Is there something you guys suggest to improve my good shield using 14C28N?

Thanks

Pablo

Last edited: