Contender Machine

Dealer / Materials Provider

- Joined

- Jun 23, 2015

- Messages

- 356

Hey Shop Talk,

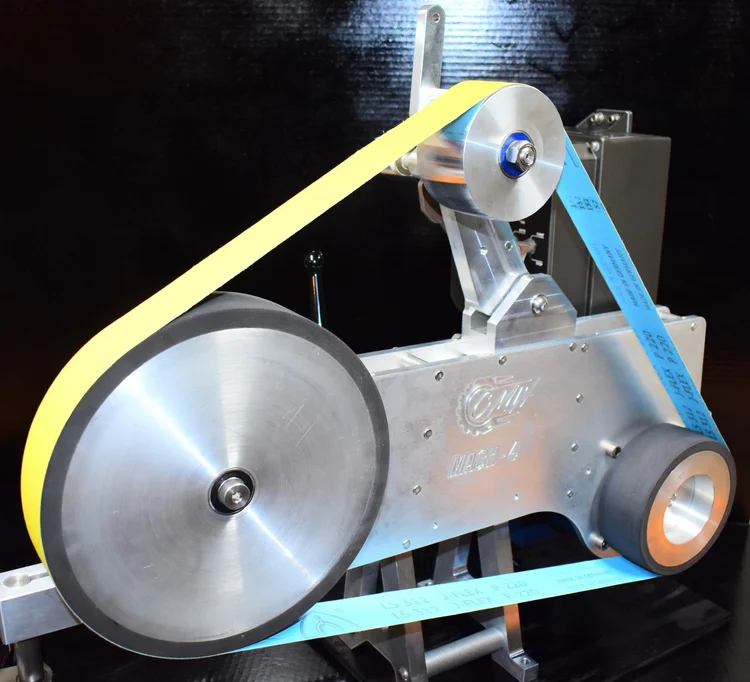

I would like to introduce the all new Contender “Mach 4” 2x72 belt grinder!

Developing this grinder has been an on going project of mine for the last few years. I chose to name this grinder the Mach 4 as the prototype of this grinder was the 4th complete grinder I have built and tested. “Machine #4” as I’ve been referring to it. I believe I have finally come up with the best all around design after trying all different kinds of tensioners, tracking mechanisms, motor configurations etc.

While some of the features are recognizable from other grinders, I have fine tuned them as best I can as well as developed some original features that are unique to this grinder. These new features, along with a quality design and manufacturing, are what make this grinder an absolute joy to run. I am proud to say that this grinder is by far the smoothest running and best tracking grinder I have ever used.

Some of the more standard/recognizable features of this grinder.

- Ratcheting tensioner. After trying springs, gas struts and pneumatic cylinders the ratchet was the simplest and most reliable.

-Simple thumb screw tilting tracking pulley. This is the most accessible and easy to use tracking setup but it’s big downside is it cannot adjust tracking on a platen while running in reverse. However this grinder has another solution to that problem.

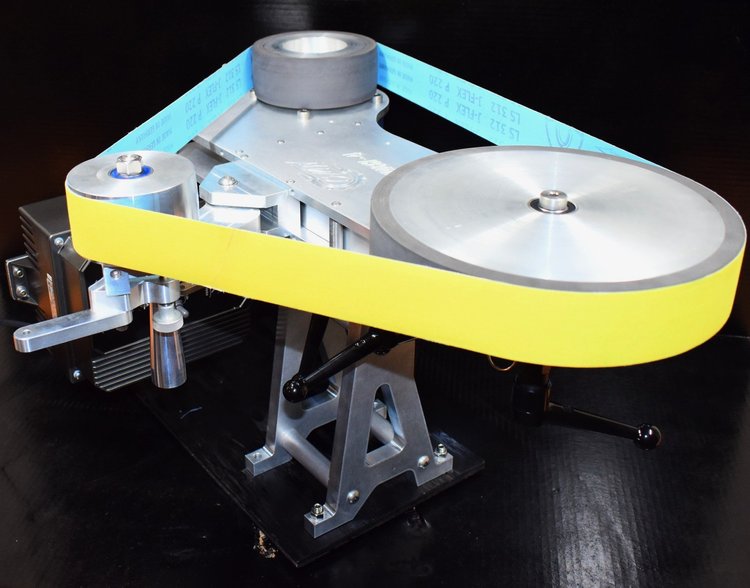

-90 degree vertical/horizontal tilting stand. Tool less and very positive locking in either position. Tight pivots and good balance mean it won’t drop violently.

-3 position 1.5 inch tool arm capacity. This is the industry standard with the most attachments available to fit.

-2hp Leeson motor with 27D VFD standard. Forward/reverse switch also standard. It’s just hard to beat this set up.

Now for a few of the unique design aspects!

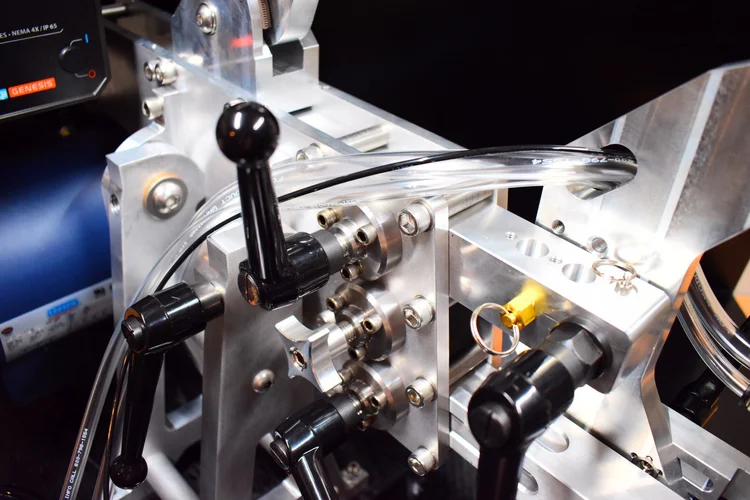

This grinder uses a quick change tool arm. All the attachments this grinder can and will be able to accept (platens, contact wheels, small wheel attachments etc) all mount to a single, fully machined aluminum tool arm. There is no need to ever remove the tool arm from the grinder. Just simply unscrew the draw bar bolt (no tools required) and the attachments come right off. They are all held on with a simple, taper locating pull stud. This makes for a very rigid and square connection to each attachment. No need to own and store a bunch of long tool arms.

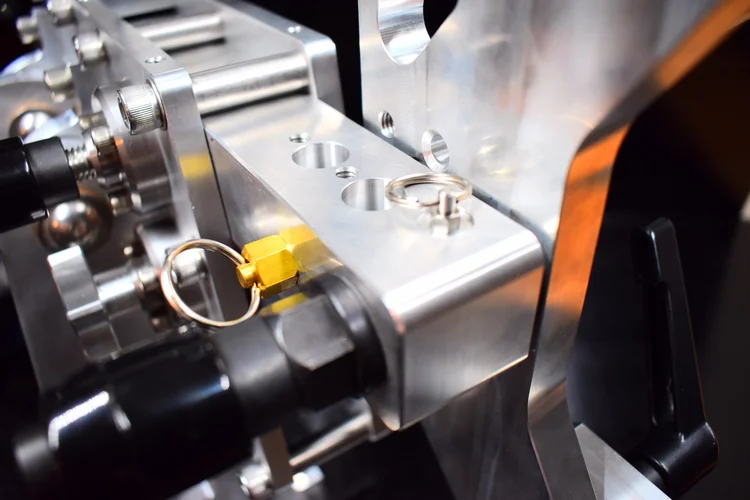

The platen system on this grinder is what really makes it track well. The platen frame is billet aluminum to make sure it is as flat as possible and the platen brackets are a quick change style so you can easily swap out different flat, radius or glass platens.

One of the biggest issues with getting platens to track well in forward and reverse is the fact that the top and bottom pulleys are what determine the position and straightness of the belt as it rides across the platen. My solution to this was to develop what I am calling Cam Arbors. These arbors are what mount the pulleys to the frame. They are fully machined from 416 stainless steel rod and have a wide base for increased stiffness and rigidity. They are also the first adjustable arbors to be put on a belt grinder! By simply turning the bolt that mounts these to the frame you can adjust belt tracking. This means you can easily tune your grinder in such a way that the belt will run perfectly parallel and centered to the platen in both forward and reverse! While I don’t have them available yet these Cam Arbors work extremely well for squaring up surface grinding attachment pulleys while under belt tension. If anyone wants to try this on there surface grinding attachment please reach out!

What is really cool about this new quick change tool arm and platen setup is they can be integrated into most any existing grinder. This setup mounted on my classic KMG grinder allowed it to track perfectly in both forward AND reverse. Something it could never do before.

The Mach 4 is built to be a high end machine. Almost all of its parts are CNC machined aluminum and stainless steel. This allows for the best quality and longest life expectancy with the least amount of maintenance. I designed and built this machine to last.

For any of you on here that don’t know who I am I’ll give a little back story here.

I have been making knives since I was a kid and after going to college and starting a career in CNC machining I began building a lot of my own tools to fuel my knife making hobby. That evolved into a business that is designed to serve the knife making community.

Using my background in mechanical engineering and CNC machining I try to build tools and provide services to fill gaps in the market. I built custom tools and knife parts for many makers so if anyone has any wild ideas or needs CNC machining done I may be able to help!

All of my tools are developed and manufactured by myself right in central Nebraska and I intend to keep it that way. Quality is definitely a high priority of mine.

I’d much appreciate it if you’d take a look at my site:

https://www.contenderworks.com/

Also, feel free to sign up for my email newsletter to get updates on new products and sales!

I’ll add some more pictures of the grinder down below.

Happy grinding!

Darren Nutt

Owner of Contender Machine Works LLC

I would like to introduce the all new Contender “Mach 4” 2x72 belt grinder!

Developing this grinder has been an on going project of mine for the last few years. I chose to name this grinder the Mach 4 as the prototype of this grinder was the 4th complete grinder I have built and tested. “Machine #4” as I’ve been referring to it. I believe I have finally come up with the best all around design after trying all different kinds of tensioners, tracking mechanisms, motor configurations etc.

While some of the features are recognizable from other grinders, I have fine tuned them as best I can as well as developed some original features that are unique to this grinder. These new features, along with a quality design and manufacturing, are what make this grinder an absolute joy to run. I am proud to say that this grinder is by far the smoothest running and best tracking grinder I have ever used.

Some of the more standard/recognizable features of this grinder.

- Ratcheting tensioner. After trying springs, gas struts and pneumatic cylinders the ratchet was the simplest and most reliable.

-Simple thumb screw tilting tracking pulley. This is the most accessible and easy to use tracking setup but it’s big downside is it cannot adjust tracking on a platen while running in reverse. However this grinder has another solution to that problem.

-90 degree vertical/horizontal tilting stand. Tool less and very positive locking in either position. Tight pivots and good balance mean it won’t drop violently.

-3 position 1.5 inch tool arm capacity. This is the industry standard with the most attachments available to fit.

-2hp Leeson motor with 27D VFD standard. Forward/reverse switch also standard. It’s just hard to beat this set up.

Now for a few of the unique design aspects!

This grinder uses a quick change tool arm. All the attachments this grinder can and will be able to accept (platens, contact wheels, small wheel attachments etc) all mount to a single, fully machined aluminum tool arm. There is no need to ever remove the tool arm from the grinder. Just simply unscrew the draw bar bolt (no tools required) and the attachments come right off. They are all held on with a simple, taper locating pull stud. This makes for a very rigid and square connection to each attachment. No need to own and store a bunch of long tool arms.

The platen system on this grinder is what really makes it track well. The platen frame is billet aluminum to make sure it is as flat as possible and the platen brackets are a quick change style so you can easily swap out different flat, radius or glass platens.

One of the biggest issues with getting platens to track well in forward and reverse is the fact that the top and bottom pulleys are what determine the position and straightness of the belt as it rides across the platen. My solution to this was to develop what I am calling Cam Arbors. These arbors are what mount the pulleys to the frame. They are fully machined from 416 stainless steel rod and have a wide base for increased stiffness and rigidity. They are also the first adjustable arbors to be put on a belt grinder! By simply turning the bolt that mounts these to the frame you can adjust belt tracking. This means you can easily tune your grinder in such a way that the belt will run perfectly parallel and centered to the platen in both forward and reverse! While I don’t have them available yet these Cam Arbors work extremely well for squaring up surface grinding attachment pulleys while under belt tension. If anyone wants to try this on there surface grinding attachment please reach out!

What is really cool about this new quick change tool arm and platen setup is they can be integrated into most any existing grinder. This setup mounted on my classic KMG grinder allowed it to track perfectly in both forward AND reverse. Something it could never do before.

The Mach 4 is built to be a high end machine. Almost all of its parts are CNC machined aluminum and stainless steel. This allows for the best quality and longest life expectancy with the least amount of maintenance. I designed and built this machine to last.

For any of you on here that don’t know who I am I’ll give a little back story here.

I have been making knives since I was a kid and after going to college and starting a career in CNC machining I began building a lot of my own tools to fuel my knife making hobby. That evolved into a business that is designed to serve the knife making community.

Using my background in mechanical engineering and CNC machining I try to build tools and provide services to fill gaps in the market. I built custom tools and knife parts for many makers so if anyone has any wild ideas or needs CNC machining done I may be able to help!

All of my tools are developed and manufactured by myself right in central Nebraska and I intend to keep it that way. Quality is definitely a high priority of mine.

I’d much appreciate it if you’d take a look at my site:

https://www.contenderworks.com/

Also, feel free to sign up for my email newsletter to get updates on new products and sales!

I’ll add some more pictures of the grinder down below.

Happy grinding!

Darren Nutt

Owner of Contender Machine Works LLC