Mistwalker

Gold Member

- Joined

- Dec 22, 2007

- Messages

- 18,679

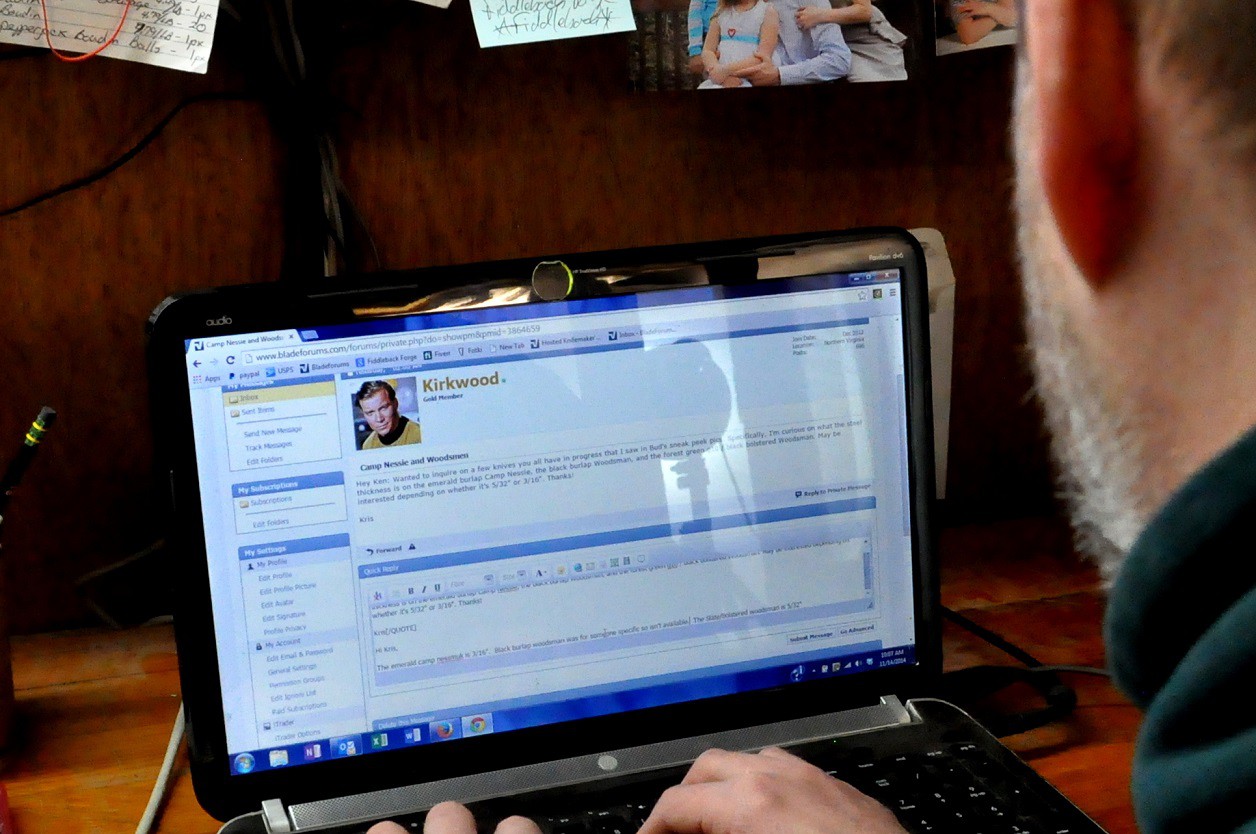

I have been following the work of Andy and the crew at Fiddleback Forge for several years now. I always enjoy talking to the guys and seeing their wares at Blade. I own Fiddleback knives that I carry regularly in the field in my work, and I have put several through some pretty hard paces over the last six years or so. I think the knives are wonderfully done and very well made, but I have also always really like the feeling of the energy, what I refer to as the soul or spirit of these knives. When you look at them, feel them, and then use them long term, it is clear the knives are crafted by someone who really loves what they do, and who really cares about the tools they produce.

I have been wanting to stop in the shop, and see the work in progress for several years now, but have never really had the time, and I have always hated the idea of imposing. However recently, while working in the general area I was given the opportunity to stop in and attempt to capture the process in images. I didn't stop anyone to ask questions, I understand the process that goes into making knives. I wanted to maintain a level of unobtrusiveness and capture things as they happened, the way they normally flow.

The following is a series of images that tell the story of the weekly road to the Friday sales posts in the Fiddleback Forge sub-forum. It is a series of photos that illustrates the effort, level of craftsmanship, and love for the craft that goes into the knives that are handcrafted by Andy Roy and his team at Fiddleback Forge. I hope you enjoy viewing them as much as I enjoyed taking and going through them.

Some things to note here are; the absence of automated machinery, it's very hands on. Also, the protective gear being worn and the attention to detail that is paid. As well as the temperature conditions at times. You will notice a space heater in use even while a lot of physical exertion is being expended, and if you look close you will see ice building up on the inside of a face shield. As I said, this is a very dedicated group of individuals who work very hard performing a job they love dearly, into order to produce highly functional works of art.

The shop entrance lets you know where you are.

Since by most accounts a knife is defined as a sharpened piece of steel with a handle, obviously the first step is to shape the steel. This process begins with tracing patterns of blade profiles onto dykem coated steel stock.

Those are then cut into individual pieces, and the knife blanks profiled out on a belt grinder.

Once shaped the the blanks are scribed, and then the holes are drilled for the pins and bullseye.

As you can see, the dykem is also applied the the blade end of the blank on the opposite for the grinding of the primary bevels. The the tangs are tapered and the primary bevels ground. Watching Andy grind the bevels was something to see. The man is very talented.

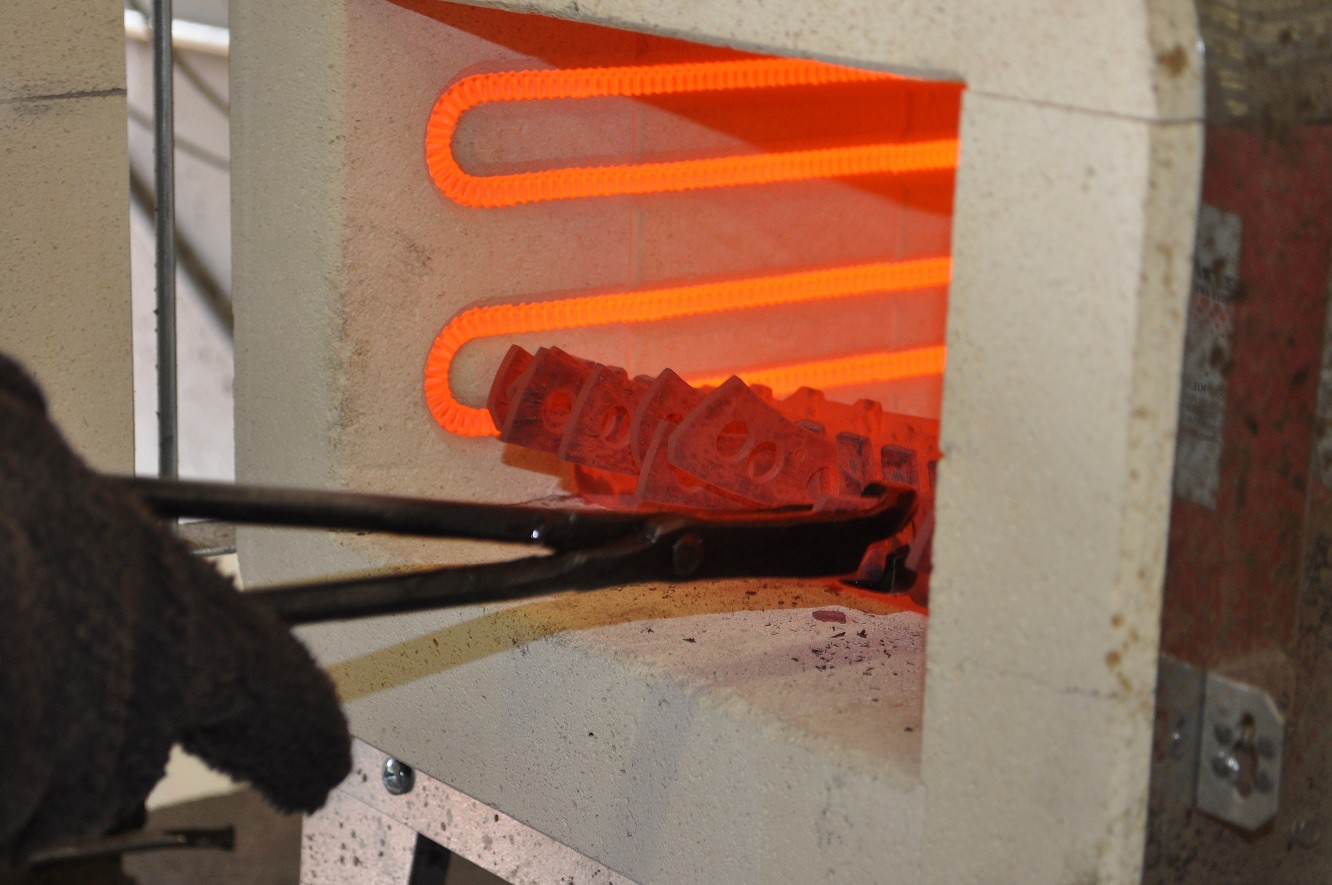

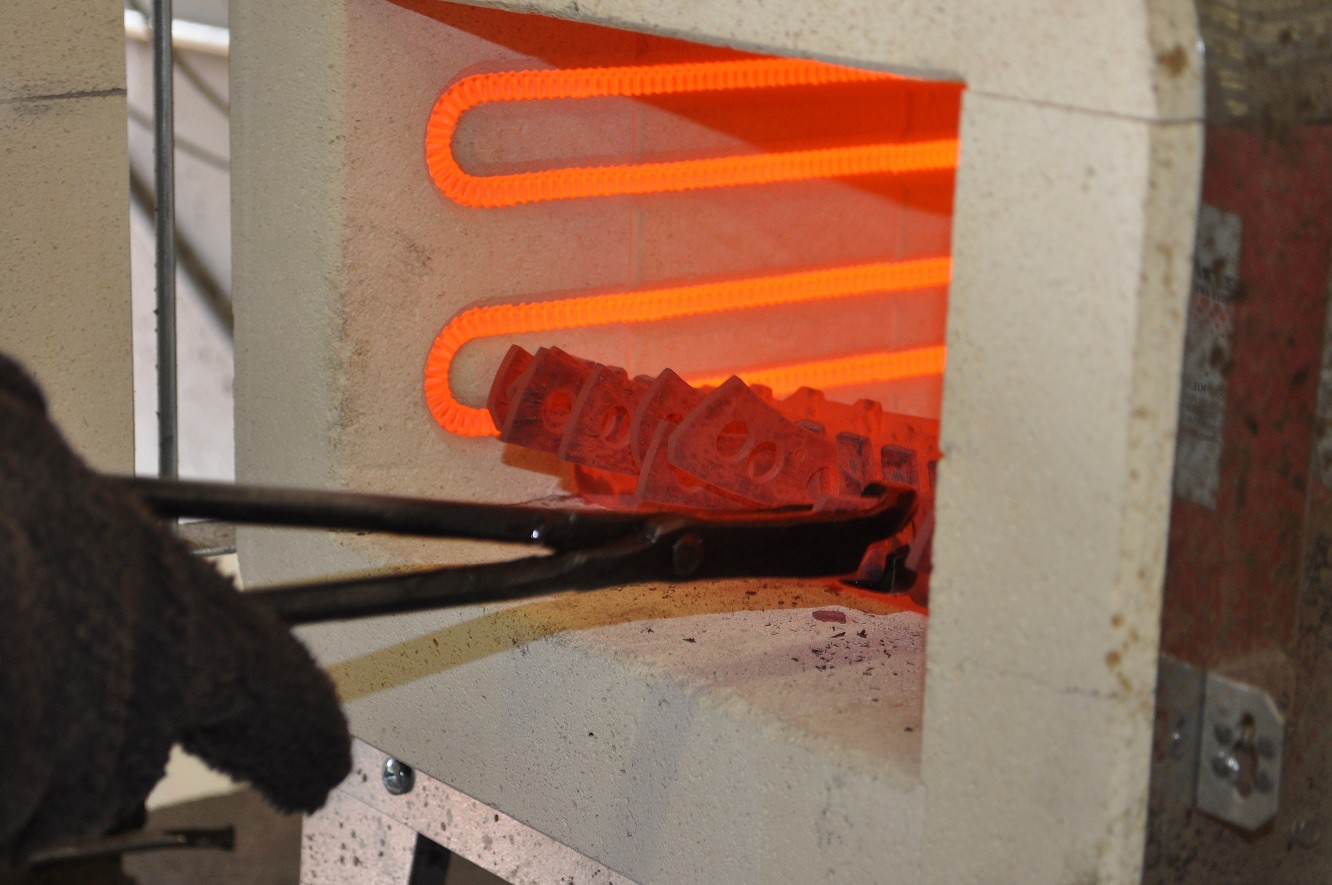

Next, the shaped blanks go into the oven for heat treatment, then the quench, and afterward allowed to cool.

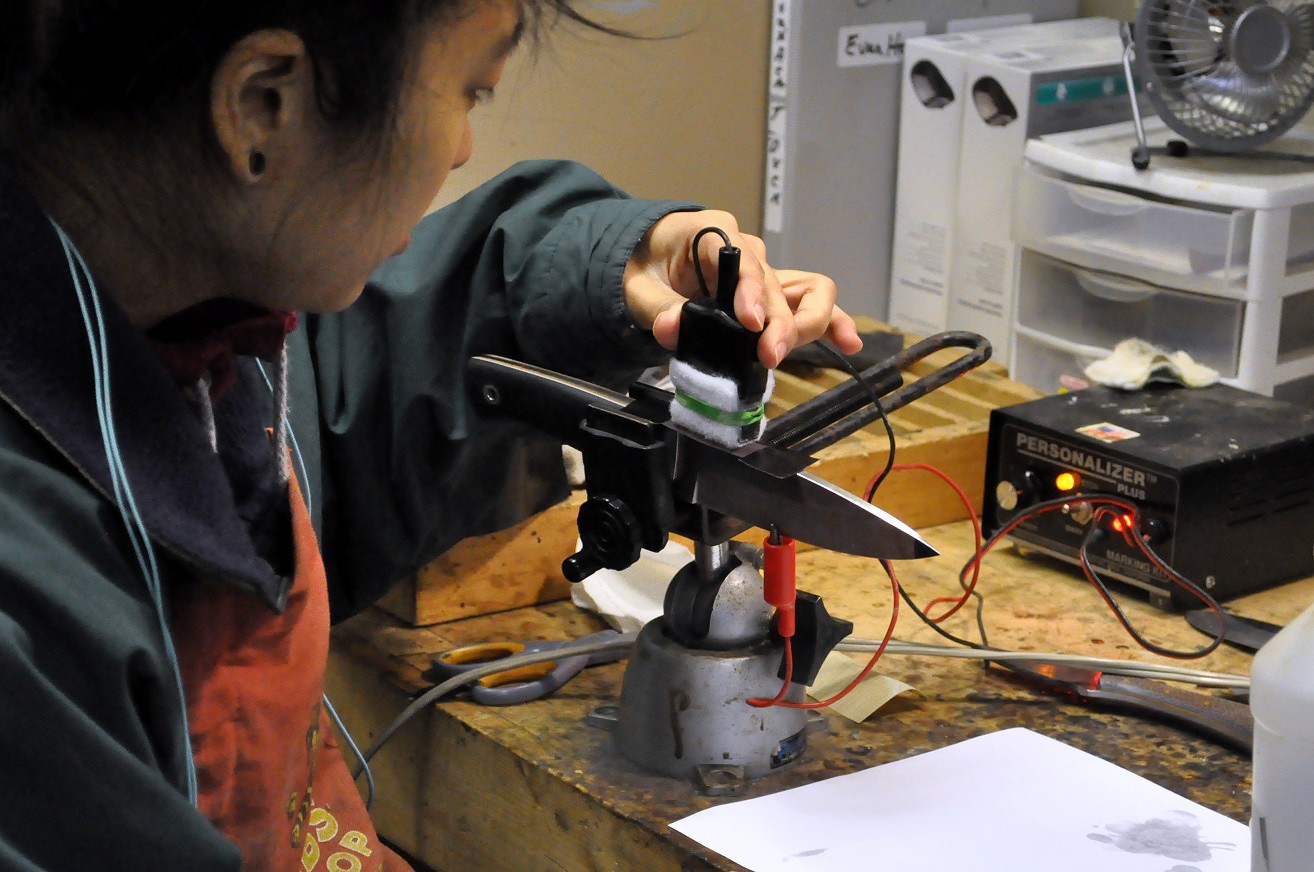

The heat treated blanks are then scribed for grinding, and then they are cleaned up with the grinds being taken to the next stage.

I have been wanting to stop in the shop, and see the work in progress for several years now, but have never really had the time, and I have always hated the idea of imposing. However recently, while working in the general area I was given the opportunity to stop in and attempt to capture the process in images. I didn't stop anyone to ask questions, I understand the process that goes into making knives. I wanted to maintain a level of unobtrusiveness and capture things as they happened, the way they normally flow.

The following is a series of images that tell the story of the weekly road to the Friday sales posts in the Fiddleback Forge sub-forum. It is a series of photos that illustrates the effort, level of craftsmanship, and love for the craft that goes into the knives that are handcrafted by Andy Roy and his team at Fiddleback Forge. I hope you enjoy viewing them as much as I enjoyed taking and going through them.

Some things to note here are; the absence of automated machinery, it's very hands on. Also, the protective gear being worn and the attention to detail that is paid. As well as the temperature conditions at times. You will notice a space heater in use even while a lot of physical exertion is being expended, and if you look close you will see ice building up on the inside of a face shield. As I said, this is a very dedicated group of individuals who work very hard performing a job they love dearly, into order to produce highly functional works of art.

The shop entrance lets you know where you are.

Since by most accounts a knife is defined as a sharpened piece of steel with a handle, obviously the first step is to shape the steel. This process begins with tracing patterns of blade profiles onto dykem coated steel stock.

Those are then cut into individual pieces, and the knife blanks profiled out on a belt grinder.

Once shaped the the blanks are scribed, and then the holes are drilled for the pins and bullseye.

As you can see, the dykem is also applied the the blade end of the blank on the opposite for the grinding of the primary bevels. The the tangs are tapered and the primary bevels ground. Watching Andy grind the bevels was something to see. The man is very talented.

Next, the shaped blanks go into the oven for heat treatment, then the quench, and afterward allowed to cool.

The heat treated blanks are then scribed for grinding, and then they are cleaned up with the grinds being taken to the next stage.

Last edited: