-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trying to identify and restore

- Thread starter Dajaalexand

- Start date

- Joined

- Jan 1, 2022

- Messages

- 5

New item by David Alexander

photos.app.goo.gl

photos.app.goo.gl

- Joined

- Jun 5, 2019

- Messages

- 759

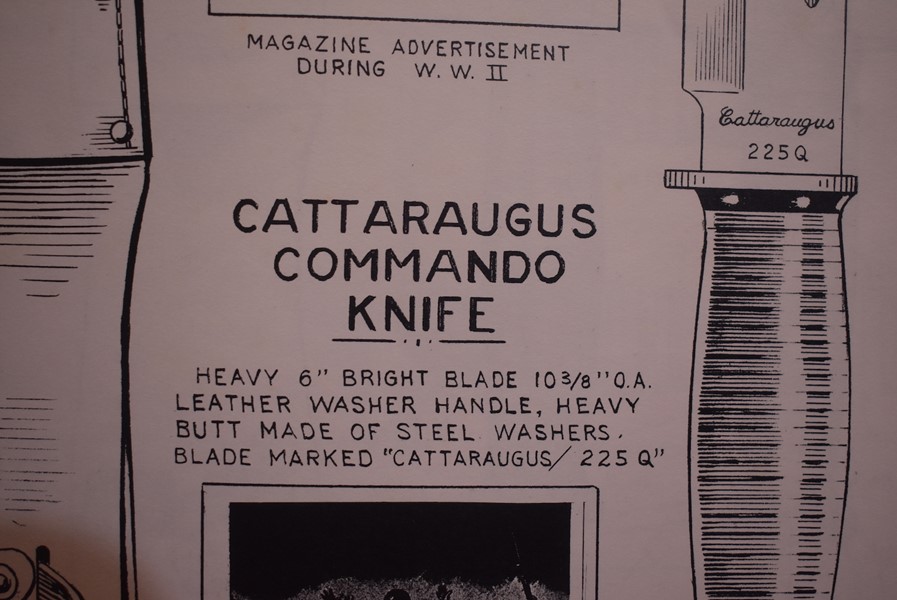

Welcome! if you can get close up of any markings that's always helpful in getting more specific identification. Here is the pictures for anyone who can't see it.

View attachment 1713025

View attachment 1713025

"The “Q” Knives of WW II

By Frank Trzaska 2004

....Designed by the Quartermaster Corps, the Bill of Materials list was number B/M No. TJC7

dated 12/1/1942 the official nomenclature is "Special Hunting Knives, 6", No.225.”

The Bill of Materials for 1000 knives included 904 lbs. of High Carbon hot rolled cutlery

blade steel. Carbon content to be not less the 1.0% while not more the 1.1% (this amounts

to basic 1095) and 211 lbs. cold rolled SAE 1010 steel was called for in the manufacture

of the guards and butt plates. A later Bill of Materials was issued to Case with the knife

designated No.337, we do not know the reason for this change but suspect the change in

handle design. These procurements were handled by the Jefferson City Quartermaster

Depot, which had control over most of the cutleries in the Northeast U.S. We list the

above as absolute proof that the Q knives were Quartermaster designed and procured for

military issue. But you say we already knew that, it is part of that myth you were talking

about. Well we still have more to the story.

...As for the knives themselves they are about the most robust knives ever made for the

military. The myth about opening crates could actually have some truth to it; these knives

are capable of doing it. And the thick pommels are more then capable of driving nails

although a tent peg is much more likely to be struck by the butt. The Cattaraugus consists

of a 1095 steel blade that is 6 inches in length with the knife having an overall length of

10 3/8 inches. The Case knife shares the same blade length but comes in at 10 inches

overall. To my hand the longer Case handle is more comfortable but the Catt is adequate

to do the job. Both knives have a stacked leather washer handle but the finish is very

much different. The typical Catt knife has a smooth leather handle roughed up in the

center section with gouges to the leather for a sure grip. The cutting tool intentionally

applied the gouges; it is not a mistake. The Case knife is finished on a broaching wheel

with 18 circular grooves which produces a much more professional and eye pleasing

result. Both knives allow a good grip surface it’s just that the Case knife looks better. The

pommels of the two knives are quite different. They both have the same dimensions but

the Case knife consists of one large piece of steel while the Catt knife uses three

independent steel disks stacked on top of each other and finished off with two nails

driven through line up holes on the disks into the leather. It is a simple yet ingenious

system to secure the pommel with a minimum amount of trouble and it is extremely

strong. In fact I do not think I have ever seen a Q knife with the pommel broken off. Both

knives have the pommel faces finished off in a waffle pattern. This could have no other

reason that I am aware of other then preventing the pommel from slipping while

hammering. Now whether driving nails or tent pegs you can take your choice but there is

no doubt it was made for hammering...."

The Q Knives of WWII

Years ago, when I bought my Cattaraugus 225-Q knife, there was some discussion among collectors as to whether this was a military issue knife or a private purchase one. The discussion was spurred by ads describing the 225-Q knife as a “Commando” knife and showing drawings of soldiers jumping out ...

www.usmilitariaforum.com

Last edited:

afishhunter

Basic Member

- Joined

- Oct 21, 2014

- Messages

- 14,918

Preserve what's there, not make it look new.

Hit the blade with oil soaked 0000 Steelwool at most. Rubbing with an oil soaked rag will also get rid of any active red rust.

Don't worry about removing the patina. It doesn't hurt anything,and helps protect against rust.

After cleaning the blade, lightly oil it with Mineral oil or 3 in one.

If the handle is wood or plastic, wash with warm soapy water and a toothbrush. If leather, use saddle soap.

Hit the blade with oil soaked 0000 Steelwool at most. Rubbing with an oil soaked rag will also get rid of any active red rust.

Don't worry about removing the patina. It doesn't hurt anything,and helps protect against rust.

After cleaning the blade, lightly oil it with Mineral oil or 3 in one.

If the handle is wood or plastic, wash with warm soapy water and a toothbrush. If leather, use saddle soap.