- Joined

- Apr 3, 2011

- Messages

- 5,956

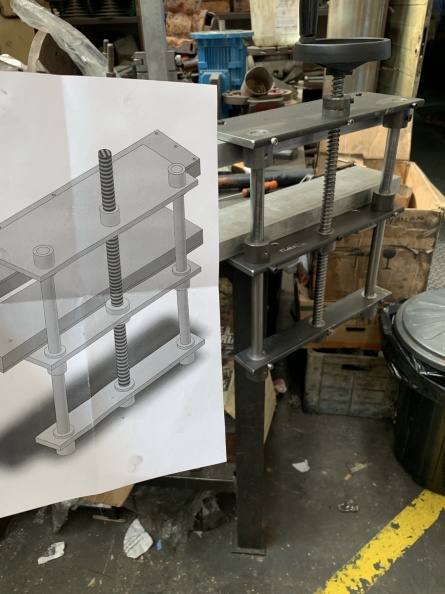

Does anyone make these? Has anyone custom made some? Would love to hear thoughts /experiences.

I'm thinking about designing/making some based off of @Nathan the Machinist chiller platen design.

I think I saw where grimsmo made some and they run antifreeze through it.

Ideally I want to set up a custom made pneumatic press with water cooled quench plates. I could really pump out some blades this way I think with the dewar being the limiting factor (a couple wide mouths may be perfect).

I'm thinking about designing/making some based off of @Nathan the Machinist chiller platen design.

I think I saw where grimsmo made some and they run antifreeze through it.

Ideally I want to set up a custom made pneumatic press with water cooled quench plates. I could really pump out some blades this way I think with the dewar being the limiting factor (a couple wide mouths may be perfect).