- Joined

- Feb 12, 1999

- Messages

- 698

Hi all,

want to show you a small and simple but effective working way i constructed and 3D printed for my grinder. BTW, I print with PETG only so this prints are really tough.

A simple solution for wet grinding, it is attached on top of my grinder with 4 magnets which are inside the housing.

This dropper can be regulated and is made for standard 2" wide belts.

What you all think?

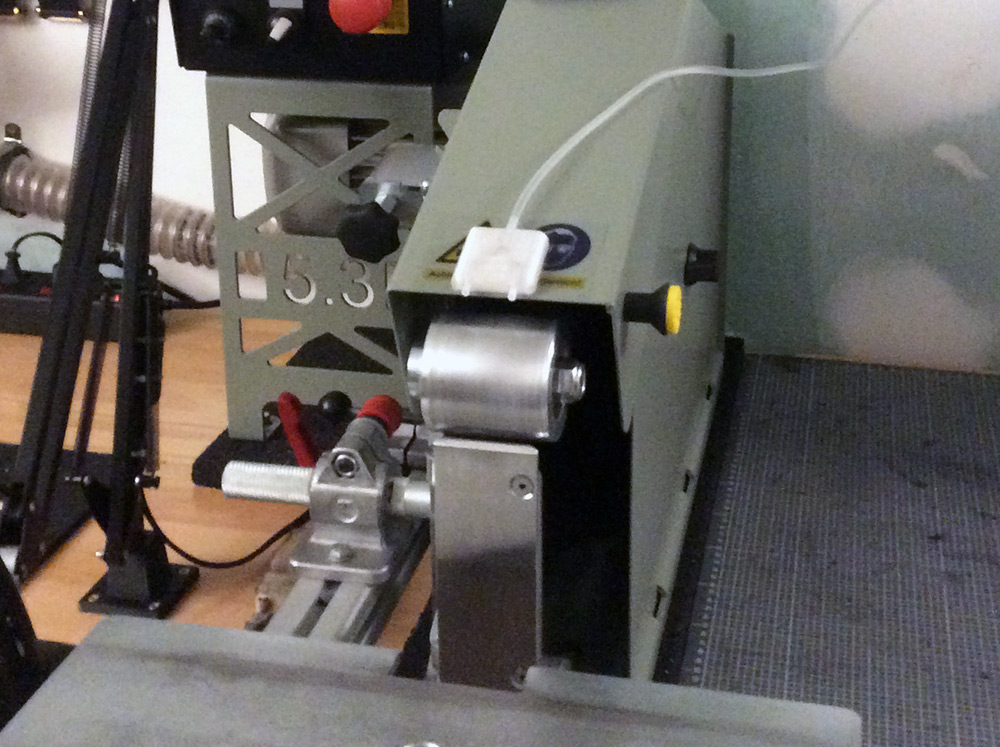

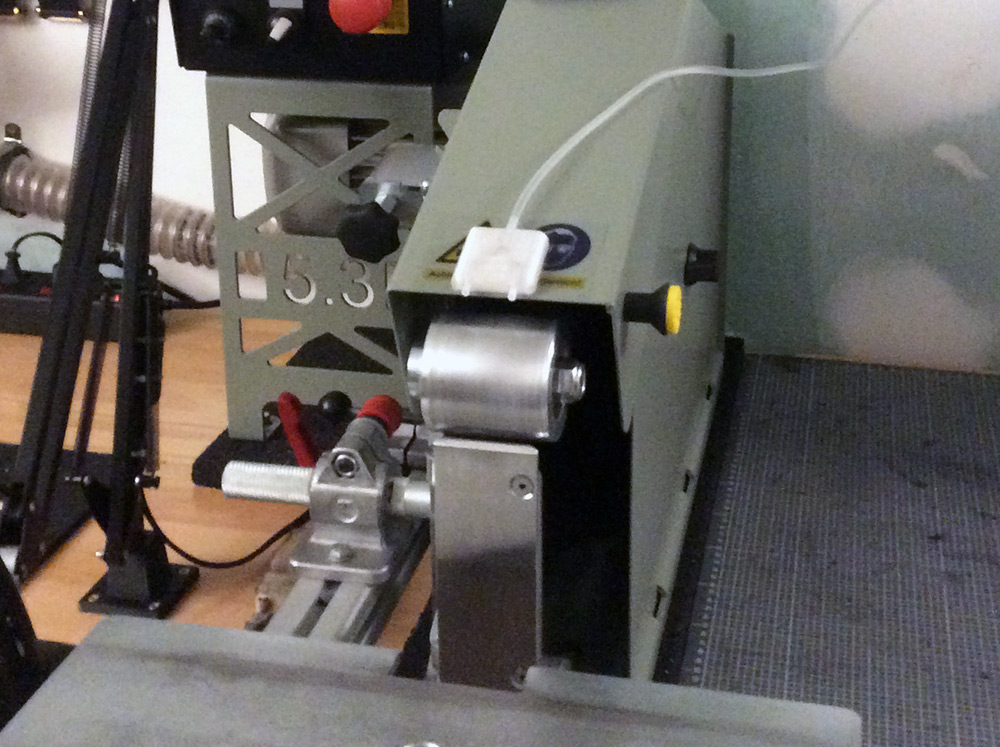

On the grinder in place:

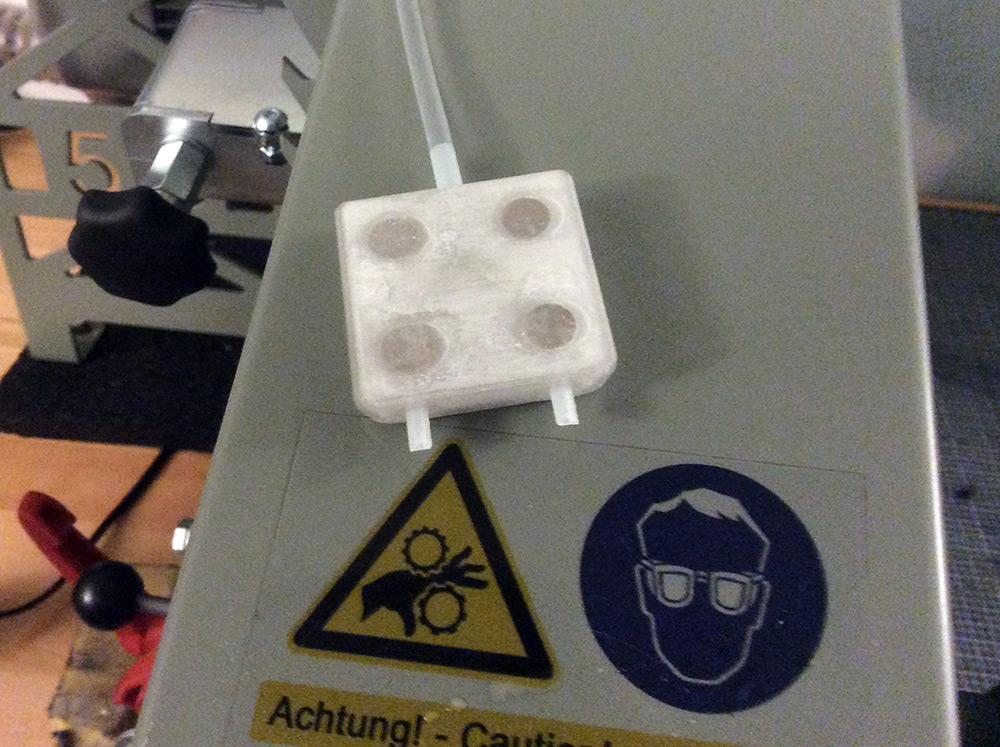

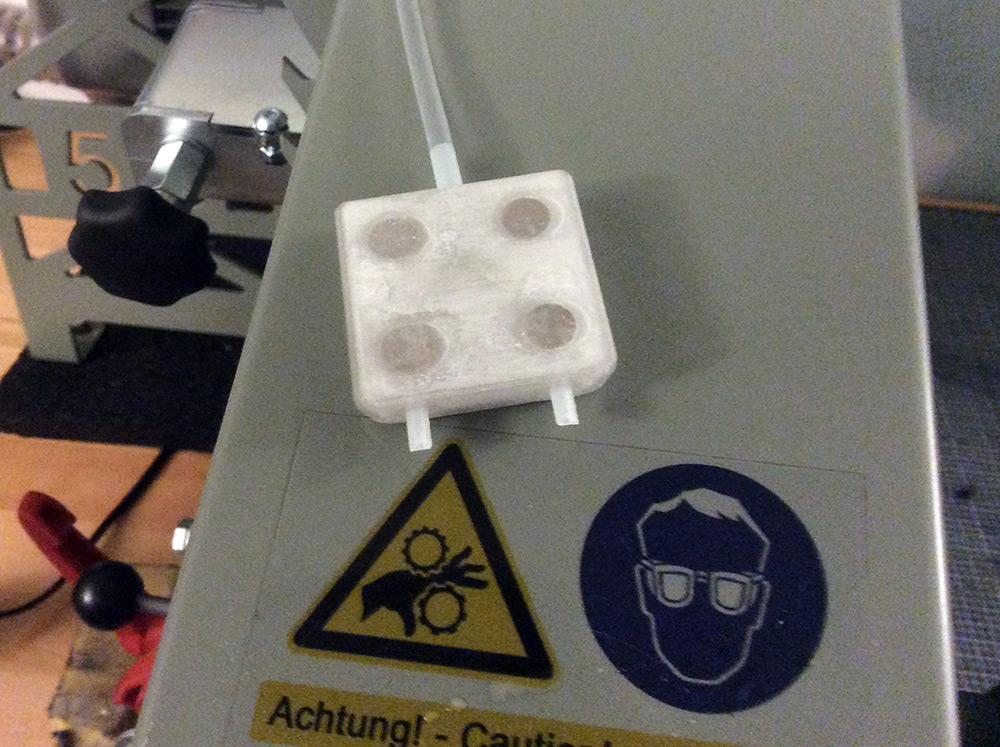

Backside, showing the magnets:

And some vid showing it in action:

want to show you a small and simple but effective working way i constructed and 3D printed for my grinder. BTW, I print with PETG only so this prints are really tough.

A simple solution for wet grinding, it is attached on top of my grinder with 4 magnets which are inside the housing.

This dropper can be regulated and is made for standard 2" wide belts.

What you all think?

On the grinder in place:

Backside, showing the magnets:

And some vid showing it in action: