-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is the Grit Standard?

- Thread starter Rhodies

- Start date

That is a GREAT question, I've wondered that too.

From working in other fields, I'm gonna guess that there IS no "THE standard", there are just standardS used by different groups/organizations for different purposes. Some places like Baryonyx will list the grits of their stones in multiple standards, which is helpful.

From working in other fields, I'm gonna guess that there IS no "THE standard", there are just standardS used by different groups/organizations for different purposes. Some places like Baryonyx will list the grits of their stones in multiple standards, which is helpful.

- Joined

- Aug 26, 2011

- Messages

- 250

My guess standard is micron, but I never saw a stone marked as it.

Ya know---I wonder if there's a handy web page somewhere that does "sharpening standard conversions" quickly? The lazy software developer in me wants that to exist, so I don't have to go run the conversions myself.

I can't find a real-time JIS > ANSI > FEPA calculator yet, but there are a few online hard-coded conversion charts, like this one:

https://www.fine-tools.com/G10019.html

I can't find a real-time JIS > ANSI > FEPA calculator yet, but there are a few online hard-coded conversion charts, like this one:

https://www.fine-tools.com/G10019.html

Last edited:

- Joined

- Mar 8, 2008

- Messages

- 26,145

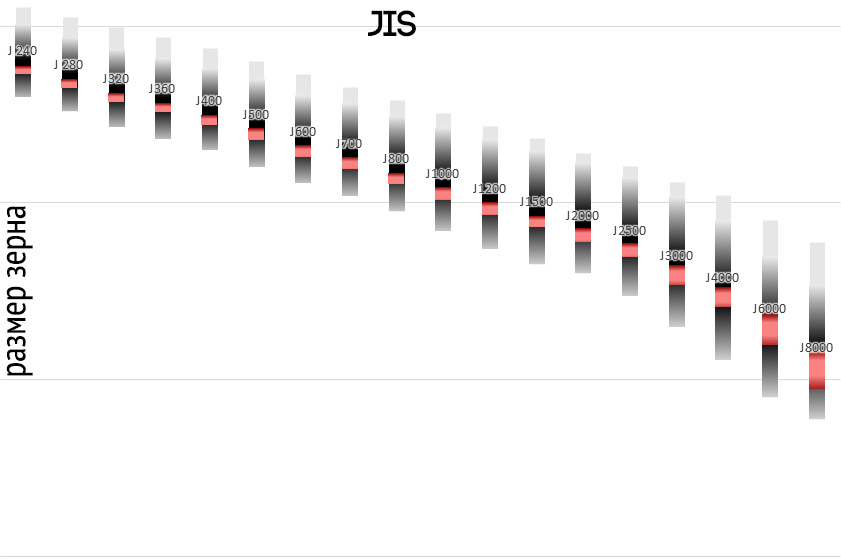

I'd say that THE standard (i.e. that which is most universal) is microns (µ). However, it's more common for places to make use of FEPA or JIS grits, or even other less common standards, and not bother stating what standard they use. Most grit standards are nearly the same in the double-digit end of the scale but begin to diverge more and more significantly the higher you go.

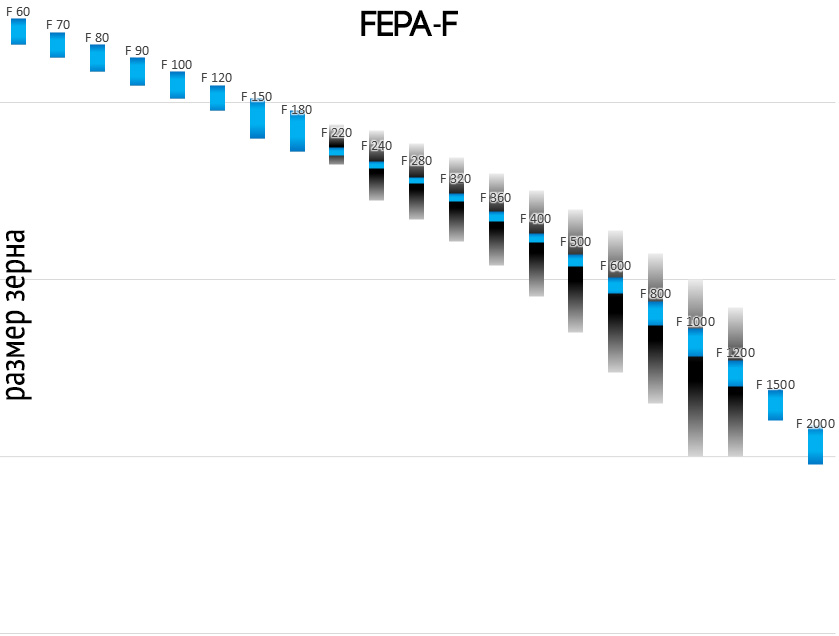

In FEPA (European standards) there are separate grit size standards for coated abrasives like sandpaper (FEPA P) and bonded abrasives like most stones and grinding wheels (FEPA F).

Grit designations under different systems have different ranges of particle size considered as acceptable maximum, minimum, and average effective size, all in microns.

In FEPA (European standards) there are separate grit size standards for coated abrasives like sandpaper (FEPA P) and bonded abrasives like most stones and grinding wheels (FEPA F).

Grit designations under different systems have different ranges of particle size considered as acceptable maximum, minimum, and average effective size, all in microns.

- Joined

- Oct 13, 2002

- Messages

- 2,008

You can refer to this post as a means of conversion to micron(s). Even so, micron ratings can only ballpark an expected finish which is also influenced by the properties of the binder and abrasive media. For example, an edge coming of a Naniwa Omura #150 can be much finer than that off of a Sun Tiger #240.

What I am facing now is the complexity of what grits to choose if I go through with the purchase of the Hapstone. The Hapstone in itself comes bundled with 3 Stone Options and in order to purchase say an extra one or two stones to assist in progression I don't want to purchase a Shapton Glass or Chosera only later to find out that my selection was actually a step back instead of a step forward in the progression. E.G., I first thought the Shapton Glass 8000 grit would be a great step going forward but as I read that chart on Gritomatics Website there is only a very marginal difference and it's best to choose the 16000 grit instead, if I am reading that chart correctly? I am basing this assumption when compared with the Basic Bundle or Aluminum Carbide Bundle. Thanks

David

David

You can refer to this post as a means of conversion to micron(s). Even so, micron ratings can only ballpark an expected finish which is also influenced by the properties of the binder and abrasive media. For example, an edge coming of a Naniwa Omura #150 can be much finer than that off of a Sun Tiger #240.

That's handy. You should seriously take useful info like that, and have the mods let you make a standalone sticky post out of it in the maintenance forum.

- Joined

- Aug 26, 2011

- Messages

- 250

Just to clarify, another doubt I have, maybe just like Rhodies, is, when you guys say I.e. I sharp my knife at 600 grit or #600 which grit are you referring to?

- Joined

- Oct 13, 2002

- Messages

- 2,008

Welcome to the wide world of sharpening where you have hundreds upon thousands of choices to choose fromWhat I am facing now is the complexity of what grits to choose if I go through with the purchase of the Hapstone.

Being that BF is based in the United States, if a grit is listed in the absence of a stated standard, I always assume ANSI....when you guys say I.e. I sharp my knife at 600 grit or #600 which grit are you referring to?

- Joined

- Mar 8, 2008

- Messages

- 26,145

Being that BF is based in the United States, if a grit is listed in the absence of a stated standard, I always assume ANSI.

Most grits that I see tossed around are JIS. ANSI stops using numbers after 1200 grit and ends at FFFF, which is 11µ average effective particle size.

- Joined

- Jan 4, 2016

- Messages

- 281

All national standards for abrasives are separated to bonded and coated version - FEPA,JIS,ANSI,GOST.In FEPA (European standards) there are separate grit size standards for coated abrasives like sandpaper (FEPA P) and bonded abrasives like most stones and grinding wheels (FEPA F).

- Joined

- Jan 4, 2016

- Messages

- 281

It's even more complicated. Standart regulates maximum and minimum for the primary fraction, and also for the secondary fraction. Abrasive may contain very big particles or very small particles in small quantity as part of secondary fraction.Grit designations under different systems have different ranges of particle size considered as acceptable maximum, minimum, and average effective size, all in microns.

Colored sections are integral distribution of the primary fraction. Grey sections are integral distribution of secondary fraction.

- Joined

- Mar 8, 2008

- Messages

- 26,145

Yup! And to make matters worse, there seem to be lots of manufacturers who use their own systems for which there's no documentation of standards available at all!

Regarding bonded vs coated, indeed there are separate distinctions under all methods, but you rarely see coated grit ratings cited (here at least) in any system other than FEPA for some reason, where I often see FEPA P get incorrectly cited where FEPA P should be used. Diamond grits also seem to have their own rating conventions.

Diamond grits also seem to have their own rating conventions.

Regarding bonded vs coated, indeed there are separate distinctions under all methods, but you rarely see coated grit ratings cited (here at least) in any system other than FEPA for some reason, where I often see FEPA P get incorrectly cited where FEPA P should be used.

- Joined

- Dec 29, 2008

- Messages

- 1,647

For comparison sake, this might be helpful: https://www.bladeforums.com/threads/the-grand-unified-grit-chart.856708/

- Joined

- Nov 10, 2011

- Messages

- 1,125

norton has a pretty good conversion chart in their industrial catalog http://www.nortonabrasives.com/site...nindustrial-7362-lr-bookmarked.pdf?t=42720482 page 64Yup! And to make matters worse, there seem to be lots of manufacturers who use their own systems for which there's no documentation of standards available at all!

Regarding bonded vs coated, indeed there are separate distinctions under all methods, but you rarely see coated grit ratings cited (here at least) in any system other than FEPA for some reason, where I often see FEPA P get incorrectly cited where FEPA P should be used.Diamond grits also seem to have their own rating conventions.

almost impossible to compare FEPA and CAMI. CAMI 600 = P1200, so maybe it is a 2x thing? wrong, CAMI 180=P180. hate it the worst when belt vendors just say a number. you order an 800 belt, thinking it will be extra fine, then you get a P800 belt that is almost the same grit as the CAMI 400 belt you were progressing from