- Joined

- Sep 13, 2017

- Messages

- 257

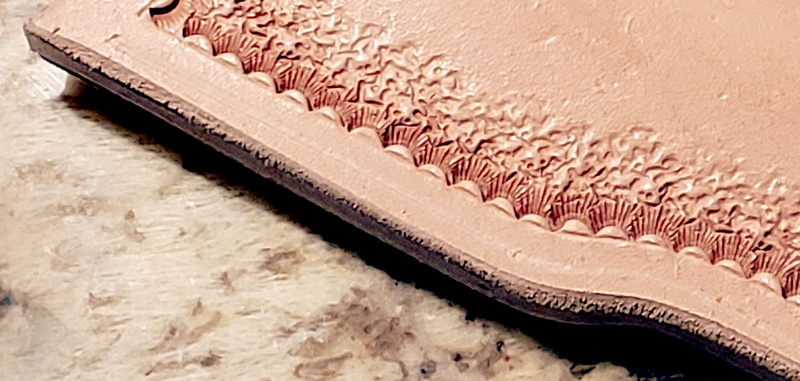

I went to Tandy's when I was first gathering tools I needed for leather working. (if only I knew there were so many more than just those I initially bought!!!) Was standing at the display where all the hand tools were hung. The manager came up to me and asked if she could help. I asked her what size edge beveler she recommended for projects like a knife sheath. She said "a #2" and reached down and grabbed one off the hook and handed it to me. I've used it in my work since then but have been disappointed with how large a bevel it makes. I was watching Youtube videos yesterday and realized the tiny little offcut from the beveler being used was tiny. Aimed a bright light at mine and the number on the shank is a #3.  The beveler she handed me had obviously been hung on the wrong hook. So what size beveler do you use for knife sheaths and projects of that size?

The beveler she handed me had obviously been hung on the wrong hook. So what size beveler do you use for knife sheaths and projects of that size?