- Joined

- May 15, 2018

- Messages

- 129

Trying to figure out what's the lowest angle one can go based on different types of steel? Couldn't find a good reference on this (maybe because its subjective?)

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Watching now. Thanks for the tip!You mean for safety razor blades ?

For a regular EDC or kitchen knife grind it very thin behind the edge and very shallow angle.

Use it for the intended work.

If it fails, gets dinged up (to some this looks like "chipping" but often with magnification it is the edge getting dinged up) . . . sharpen to a degree per side wider angle and use again. It almost depends more on the material being cut (and the heat treat) than it does the steel being used.

Have you seen the Carter Cutlery YouTube about edge geometry that I post too often ? If you haven't I can imbed it here if you like. Totally right on info. I don't agree with all things Carter but that short vid is the bee's knees, the cats meow, the . . .

Super steels can support a thinner primary grind, generally speaking, but not necessarily at the edge.

Lower than about 24° lateral stability begins to take a dump becoming more pronounced as you go, though at the edge it might still cut well if not abused. Most steels can tolerate 26° or so with no real issues tho some might do better with a small microbevel to bring the actual edge up closer to 30. Better quality steels with good HT can be run pretty thin - to where the edge deflects when pressed against a pen. But...lateral stability will be a concern.

A gross over simplification but lower alloy steels seem to support the lower angle edges, some of the super steels get pretty schizo below 15 degrees.

Russ

Hi,

Yup, searching for knife info can be difficult

Metallurgist Dr. Roman Landes says, if carbide volume is 0.5-5%, to both take and hold a high polished sharpness, you need 8-12 degrees per side.

Metallurgist Dr. Roman Landes says, if carbide volume is 5-15%, to both take and hold a high polished sharpness, you need 12-20 degrees per side.

Metallurgist Dr. Roman Landes says, if carbide volume is greater than 15%, to both take and hold a high polished sharpness, you need 20-30 degrees per side.

From Romans book Messerklingen und Stahl , marthinus quotes Romans original post with updated pdf link and other good ones, I embedded image of pdf below,

cpm-m4-at-low-angles-my-experience-recently.1086828/page-2#post-12414439

roman-landes-knife-edge-diagram-angles-carbides-schneiden.png

Patent US5830287 - Wear resistant, powder metallurgy cold work tool steel articles having high ... carbide volume chart

Spyderco Sal Glesser says that he sharpens all of his knives at 15 degrees, as all of Spyderco's steels can handle it. So if you have problems at 15 degrees you should send the knife to Spyderco as defective with a chipping problem.

consider that under 15 dps edge can chop bones And 12 dps edge can still shaves/whittles beard hair after 1000 slices of hardwood ( yes a 1000 slices of hardwood )

This utility razor blade pictured here has ~10dps edge/0.017in(431.8micron), increase that to 15-25dps and try cutting up that same chicken bone, (all the other pictured knives all sharpened to 30-inclusive)

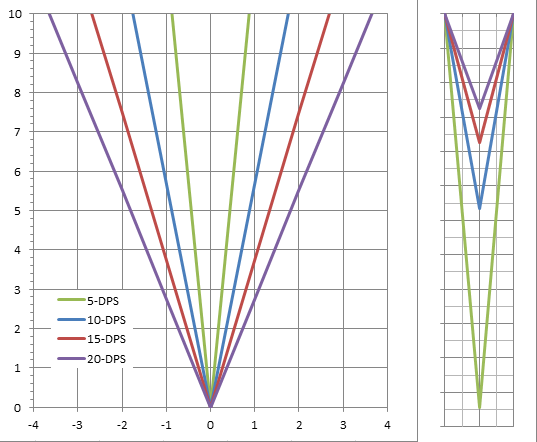

When Joe Calton mentions 0.020" thick for chopping bone, that is roughly comparable to the green blade in the diagram above. 0.020"

Compare to this image that howto measure angles thickness with calipers

Sharpening method or blade steel? Its always the geometry.

Geometry defines the limits of cutting performance, steel defines the limits of functional geometry which are influenced strongly by user skill level and physical ability.

Geometry and proper sharpening vs steel quality

To fine tune a knife, without knowing much about the numbers of the thicknesses or angles, if making a 1000 slices at a time doesnt damage the edge like this (roll/reflection or chip), keep lowering the angle

Normark EKA 12C27 : optimal edge geometry for slicing hardwoods (norton economy fine edge) - CliffStamp

So the way I think about edge angles and thickness,

compare your edges with your fingers/eyes to utility knife razor blade

don't need to know actual thickness numbers of your edge,

if your utility knife blades dont say how thick its easy to measure with simple centimeter/mm ruler, then compare to this list, and decide go up or go down

- 4 to 6 dps (8-12 inclusive) -<0.005", light use knives, paper and cardboard, light ropes, knot free woods

- 8 to 10 dps (16-20 inclusive) -<0.005"-0.015", moder push cuts on woods, thicker plastic, heavy ropes

- 12 to 14 dps (22-28 inclusive) -<0.015"-0.025", hard push cuts on very knotty woods, bones, etc.

- 12 to 14 dps (22-28 inclusive) ->0.025" dps, chopping blades

- 0.025"/15 dps (30 inclusive) = 0.635 millimeters / 15 dps edge overbuilt , cutting into or contacting against very hard materials like rock, metals and such. It is over built for cutting but well built for durability in extremes/utility.

- 0.025"/15 dps (30 inclusive) = 0.635 millimeters / 15 dps edge overbuilt , you could chisel cut through nails and such without issues , $1 one dollar knives or $5

- 0.035"/20 dps (40 inclusive) = 0.889 mm 20 dps beyond overbuilt , $1 one dollar knives or $5

- 0.045"/25 dps (50 inclusive) = 1.143 millimeters /25 dps sillybuilt

- 25 dps and 30dps (50-60 inclusive) and higher are angles for metal cutting cold chisels or splitting wedges or a table knife

Its easy to see the truthfullness of this list, simply

take a box of utility knife razor blades and sharpen to see how low you can go.

Explode your mind through first hand experience not merely mind exploding videos, spyderco delica/pacific salt...Extreme Regrind , ~6DPS with 10dps microbevel, no damage in 50 slices into pine, hardwood flooring and plywood the edge eventually gets damaged while cutting metal (steel food can)

Leonard Lee's The Complete Guide to Sharpening recommends felling axe edge angles as low as 10-12 dps. Granted, he does qualify it by saying clean (knot free) green wood, but still. In any case, challenge accepted. We'll see what happens.

Here they says 25 degrees (12.5 degrees per side), An Ax to Grind: A Practical Ax Manual - 99232823 - FS Publications - Publications - Recreational Trails - Environment - FHWA

Most axes have a 30-40 degree angle at the end of the bit and a 15-20 degree angle about ½” from the cutting edge.

gransforsbruk

1 listed for frozen wood is 80 degrees or 40 degrees per side (cold chisel, skew chisel)

2 listed for softwood is HIGH angle at 42 degress or 21 dps

3 listed for carving is is 25 degress or 12.5 dps

For a good edge that won't be chippy if you do not abuse it is 15 degree's on most Spyderco knives for example,you also have to take into account blade thickness for example a Hinderer XM-18 I will not go past 20 degree's per side there is no point trying to take it down any lower as the blade is to thick and you won't feel any more sharpness when cutting.

I learned that lesson the hard way when I first started sharpening and you try and take a Hinderer down to 15 or less per side but it still won't be a great slicer because the blade is thicker it's better suited to a hard use knife where as Spyderco's make better slicer's for cutting box's and package's open and you can still cut rope and stuff with the over even clean a fish if need be.

It's all about the blade and how thick it is as to how low of angle you can go and you also have to look at the steel that was used in the knife and the heat treating as not all heat treatment's equal when comparing the same 2 steels.I have a Japanese chef knife that a Master of working with Shirogami 1 steel and heat treating it and his knives n that steel are 65 RC hardness and the edge does not get chippy where other makers struggle to get it to 63 to 64 without making the edge chippy.

Is it common practice to reprofile brand new knives right out the box or are stock angles normally used and reprofiled thereafter?

Is it common practice to reprofile brand new knives right out the box or are stock angles normally used and reprofiled thereafter?

Is it common practice to reprofile brand new knives right out the box or are stock angles normally used and reprofiled thereafter?