- Joined

- Feb 29, 2016

- Messages

- 1

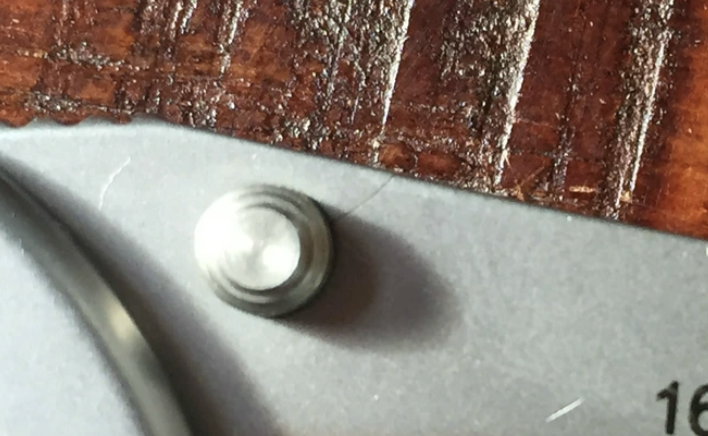

Bought this blur a week ago, carried three times, today I see this. My another blur with 14c28n steel which I carried over a year is fine.

bare links removed. do not send members offsite. please post images by editing your post, selecting the image icon and linking your images.

bare links removed. do not send members offsite. please post images by editing your post, selecting the image icon and linking your images.

Last edited by a moderator: