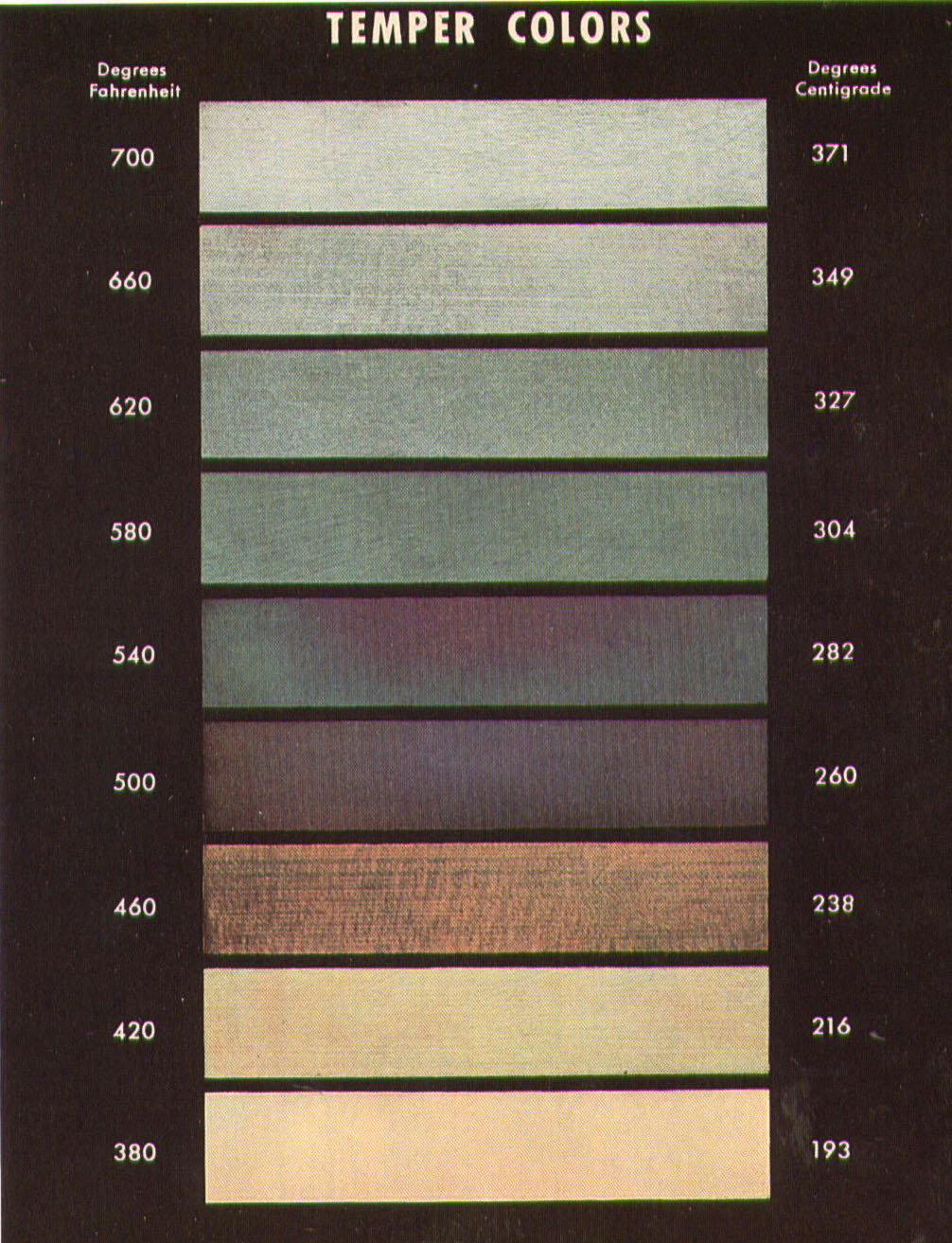

I have already heat treated and snap tempered a couple A-2 knives I was working on for a project. When I got them all cleaned up and checked their HRC they were a lot harder than I had hoped they would be (they are 61-64HRC). I would like to have them down in the 59-61 range. The problem is I am short on time and won't be able to re polish them up so I am wondering if I temper them at 350-400 will I see any discoloration and scaling? This is being done in normal atmosphere, though I can wrap them. Thanks for any advice anyone can offer.

-

The BladeForums.com 2024 Traditional Knife is ready to order! See this thread for details: https://www.bladeforums.com/threads/bladeforums-2024-traditional-knife.2003187/

Price is$300$250 ea (shipped within CONUS). If you live outside the US, I will contact you after your order for extra shipping charges.

Order here: https://www.bladeforums.com/help/2024-traditional/ - Order as many as you like, we have plenty.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will tempering cause finished A-2 to scale or discolor?

- Thread starter Mobalized

- Start date

Thank you guys very much. That answers the my question. But I have one follow up for you, the knives already have an edge put on them. The re-temper shouldn't cause any issues with cracking the edge like the hardening process could on a thin edge correct?

- Joined

- Dec 2, 2011

- Messages

- 913

Seems to me that you make might need higher temps for a2. If I recall, to hit those rockwell readings I had to go to 700ish

I ended up re tempering them and they ended up in the range of 59-60 HRC. I am pleased with that. I thought you guys might find these neat, so here are some of the pictures of the A-2, O-1, and D-2 knife edges I am doing the testing on. There is also a picture for each at 200x showing the 3D profile of the knife with a plot of its geometry at the edge. It is amazing how bad they look under 200x magnification. (their actual edge quality isn't very critical for what i'm doing).

image free hosting

image free hosting

- Joined

- Dec 2, 2011

- Messages

- 913

Cool! What grit was that?