I have a Carothers with the Delta 3V which I understand to be 3V with the Delta heat treat. It is great, although I havent tried pounding it through a bolt. I also have a Survive GSO with the D3V heat treat. I haven’t used it a lot but I am wondering if it will offer the same performance?

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A question about Delta 3V

- Thread starter DMG

- Start date

Jdottinger

Basic Member

- Joined

- Jan 11, 2015

- Messages

- 4,053

He continues on about Guy not putting out a bad product, so maybe what started the discussion was a r&d blank or a 2nd.A discussion stated when I saw an example of some work on IG that did not appear to me to demonstrate the edge stability that we strive for with this process (it's the whole purpose of this process) so I called Guy on the phone. In my discussion with him it sounded like they were dealing with some inconsistencies in the results and they finally made the decision to step back a bit into an older approach to their heat treat.

Bill Siegle

Knifemaker / Craftsman / Service Provider

- Joined

- Oct 3, 2000

- Messages

- 6,916

If you trust Survive Knives to have actually followed the Delta heat treat protocol, it should perform the same. There is some speculation as to whether they stayed true to the recipe however. I personally trust a Carothers made blade to be the best it can be when it leaves their shop. As to cutting bolts, that is destructive level testing done by makers. It’s not a normal cutting test end users should be performing unless they’re willing to accept the consequences personally.

- Joined

- Aug 20, 2022

- Messages

- 1,549

Why did I read this?

Dang it, now I want a Carothers.

Adds to the list.

Subtracts from the bank account sometime in the future.

I hate math.

Dang it, now I want a Carothers.

Adds to the list.

Subtracts from the bank account sometime in the future.

I hate math.

They are worth every penny!Why did I read this?

Dang it, now I want a Carothers.

Adds to the list.

Subtracts from the bank account sometime in the future.

I hate math.

- Joined

- Aug 20, 2022

- Messages

- 1,549

I sense that the consensus will grow.They are worth every penny!

Thank you for the reassurance.

- Joined

- Oct 18, 2018

- Messages

- 8,666

Why did I read this?

Dang it, now I want a Carothers.

Adds to the list.

Subtracts from the bank account sometime in the future.

I hate math.

*Math (Science)tells us good steel, and good heat treatment will cut bolts with optimized geometry.

Nothing more, nothing less.

Excellent steel, and Excellent heat treatment isn't exactly needed. It's awesome, but not really needed....

Knowing this "almost" makes the stunt seem like a parlor trick....

Of course we would control for the grind and geometry. Ergonomics and geometry are good on both but I do prefer the Carothers.Short answer is NO it will not have the same performance.

Heat treat protocol is only one part of a blades performance, and CPK optimizes the geometry, ergonomics, and grinds. They are phenomenal knives.

I have no plans to hammer either knife through bolts or nails. I like both knives and want them to last.If you trust Survive Knives to have actually followed the Delta heat treat protocol, it should perform the same. There is some speculation as to whether they stayed true to the recipe however. I personally trust a Carothers made blade to be the best it can be when it leaves their shop. As to cutting bolts, that is destructive level testing done by makers. It’s not a normal cutting test end users should be performing unless they’re willing to accept the consequences personally.

I have had a Carothers for several years and haven’t had nearly the urge to purchase new fixed blades since so it may be a wash financially.Why did I read this?

Dang it, now I want a Carothers.

Adds to the list.

Subtracts from the bank account sometime in the future.

I hate math.

Jsega51

Gold Member

- Joined

- Feb 11, 2015

- Messages

- 9,234

CPK has their large batches of knives heat treated to their “Delta” protocol by Peters HT who also heat treated knives for Survive so that factor alone is sort of a moot point when “performance” is discussed. As was brought up earlier, many other attributes of the knife become the way the knife should be judged and Guy doesn’t come close to Nate when true design plays into how the knife balances and fits in the hand during use, not just playing with it in the recliner, during actual use.

The nod should also be given to Lorien Arnold for his designing many CPK models; with that tag team I don’t think there’s going to be many ways a Survive knife is going to offer the same or better “performance”.

The nod should also be given to Lorien Arnold for his designing many CPK models; with that tag team I don’t think there’s going to be many ways a Survive knife is going to offer the same or better “performance”.

- Joined

- Jul 30, 2006

- Messages

- 44,673

Aside from design feature differences, If you wade through the Survive thread in GB&U there's a couple of posts discussing controlling the grain direction. There are pictures which show that some knives were cut from the steel sheet perpendicular the grain direction. (That's bad.) So there is variability in Survive knives which does not exist in Carothers blades.

(about 4:40)

It seems some of their blanks are indeed cut perpendicular to the rolling direction.

I found this in one of their videos:If this is true, that explains most of his problems with production. Blanks cut in the wrong direction are almost impossible to straighten AND have no durability. Don't ask me how I know this....

It seems some of their blanks are indeed cut perpendicular to the rolling direction.

I’ll post up pics after work and someone can tel me if they got the grain direction right.Aside from design feature differences, If you wade through the Survive thread in GB&U there's a couple of posts discussing controlling the grain direction. There are pictures which show that some knives were cut from the steel sheet perpendicular the grain direction. (That's bad.) So there is variability in Survive knives which does not exist in Carothers blades.

I found this in one of their videos:If this is true, that explains most of his problems with production. Blanks cut in the wrong direction are almost impossible to straighten AND have no durability. Don't ask me how I know this....(about 4:40)

It seems some of their blanks are indeed cut perpendicular to the rolling direction.

Nathan the Machinist

KnifeMaker / Machinist / Evil Genius

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Feb 13, 2007

- Messages

- 18,524

CPK has their large batches of knives heat treated to their “Delta” protocol by Peters HT who also heat treated knives for Survive so that factor alone is sort of a moot point when “performance” is discussed. As was brought up earlier, many other attributes of the knife become the way the knife should be judged and Guy doesn’t come close to Nate when true design plays into how the knife balances and fits in the hand during use, not just playing with it in the recliner, during actual use.

The nod should also be given to Lorien Arnold for his designing many CPK models; with that tag team I don’t think there’s going to be many ways a Survive knife is going to offer the same or better “performance”.

They did get the same heats, times, steps, and pre-staging that would, in theory, give the same results.

I have been making some small tweaks to the steel during the manufacturing process that he wasn't.

My spacing in the oven limits my batch size to a fraction of his batch size. In practice, our quench rate was not the same.

My blades are near net shape during heat treat, his blades were full thickness blanks which have a much slower quench rate at the edge.

His blades were ground hard and could possibly have been exposed to temperatures during grinding that would have an effect on an important aspect of the heat treat.

His knives were sharpened dry.

His application of the protocol ended up being a little bit different than mine. I was very concerned when I saw that knife with the Delta protocol that had significant edge damage when it shouldn't have. I reached out to him because it appeared to me that there was a problem.

I'm not saying that there's necessarily anything wrong with his work. That one example I saw looked pretty suspect to me. I don't know. But it is my opinion that his application of the Delta protocol might not have been the same as mine. It might have been a little bit borderline which would explain why he backed up to an older protocol for his process.

Nathan the Machinist

KnifeMaker / Machinist / Evil Genius

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Feb 13, 2007

- Messages

- 18,524

A low temperature tweak can be worse than a standard process, if you don't stay on top of stabilizing retained austenite.

Also, there is an aspect to some heat treats that are heat sensitive that don't significantly affect measured hardness, but do have a measurable effect on the behavior of the edge. I stay away from hard grinding and dry sharpening to avoid causing a problem that I don't have a good mechanism to catch.

Also, there is an aspect to some heat treats that are heat sensitive that don't significantly affect measured hardness, but do have a measurable effect on the behavior of the edge. I stay away from hard grinding and dry sharpening to avoid causing a problem that I don't have a good mechanism to catch.

Nathan the Machinist

KnifeMaker / Machinist / Evil Genius

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Feb 13, 2007

- Messages

- 18,524

I’ll post up pics after work and someone can tel me if they got the grain direction right.

You're not going to be able to look at a finished knife and determine grain direction by just looking at it.

You can have your sheet cross rolled 50/50 and have no grain bias. It's possible, in that picture, it might not matter. I don't know.

On swords, I have the sheet rolled with extra bias.

I'm about to make some planer blades where we are intentionally putting the bias perpendicular to the blade because the well supported blade is not going to break, but the edge might. And that little bit of a toughness bump is actually more useful across the edge, rather than along it.

Grain is an important element to consider, but it is not always right or wrong. It would be fully appropriate to do it "wrong" on certain kinds of knives.

You're not going to be able to look at a finished knife and determine grain direction by just looking at it.

You can have your sheet cross rolled 50/50 and have no grain bias. It's possible, in that picture, it might not matter. I don't know.

On swords, I have the sheet rolled with extra bias.

I'm about to make some planer blades where we are intentionally putting the bias perpendicular to the blade because the well supported blade is not going to break, but the edge might. And that little bit of a toughness bump is actually more useful across the edge, rather than along it.

Grain is an important element to consider, but it is not always right or wrong. It would be fully appropriate to do it "wrong" on certain kinds of knives.

I had a reblade heat treated by a knife maker known for using A8(mod). The idea behind using that steel was to allow the knife to do some light chopping of branches, which -- because of uneven grain changes in the wood -- can create some severe stresses along the edge.

All the maker had was a small scrap of A8(mod) that was barely large enough to made a 4-inch blade. I asked about the grain direction, and was told it was OK, but I now have my doubts.

Using this super-tough steel in the same way as an exactly paired blade with the same geometry and shape in Vanax (both replaces for a Benchmade Rukus 610), the A8(mod) failed and the Vanax did not.

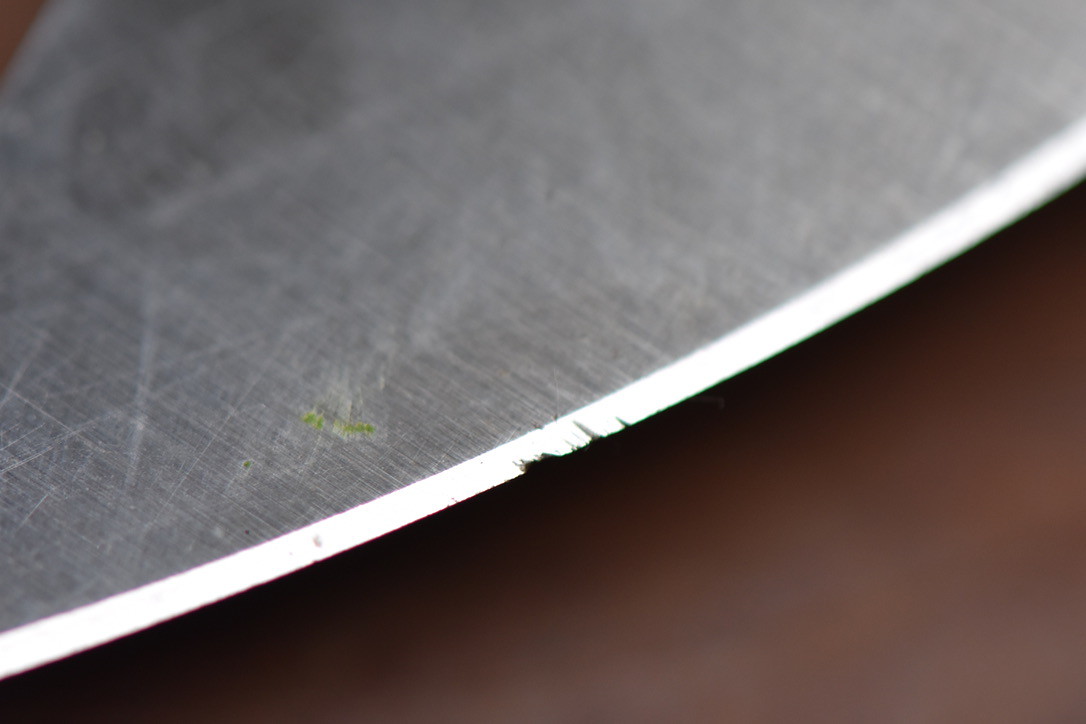

Here's a shot of the A8(mod) blade <60 Rc that chipped, but also cracked along what seems to be (although I really don't know for sure) poor grain direction.