- Joined

- Oct 18, 2018

- Messages

- 8,666

I had a reblade heat treated by a knife maker known for using A8(mod). The idea behind using that steel was to allow the knife to do some light chopping of branches, which -- because of uneven grain changes in the wood -- can create some severe stresses along the edge.

All the maker had was a small scrap of A8(mod) that was barely large enough to made a 4-inch blade. I asked about the grain direction, and was told it was OK, but I now have my doubts.

Using this super-tough steel in the same way as an exactly paired blade with the same geometry and shape in Vanax (both replaces for a Benchmade Rukus 610), the A8(mod) failed and the Vanax did not.

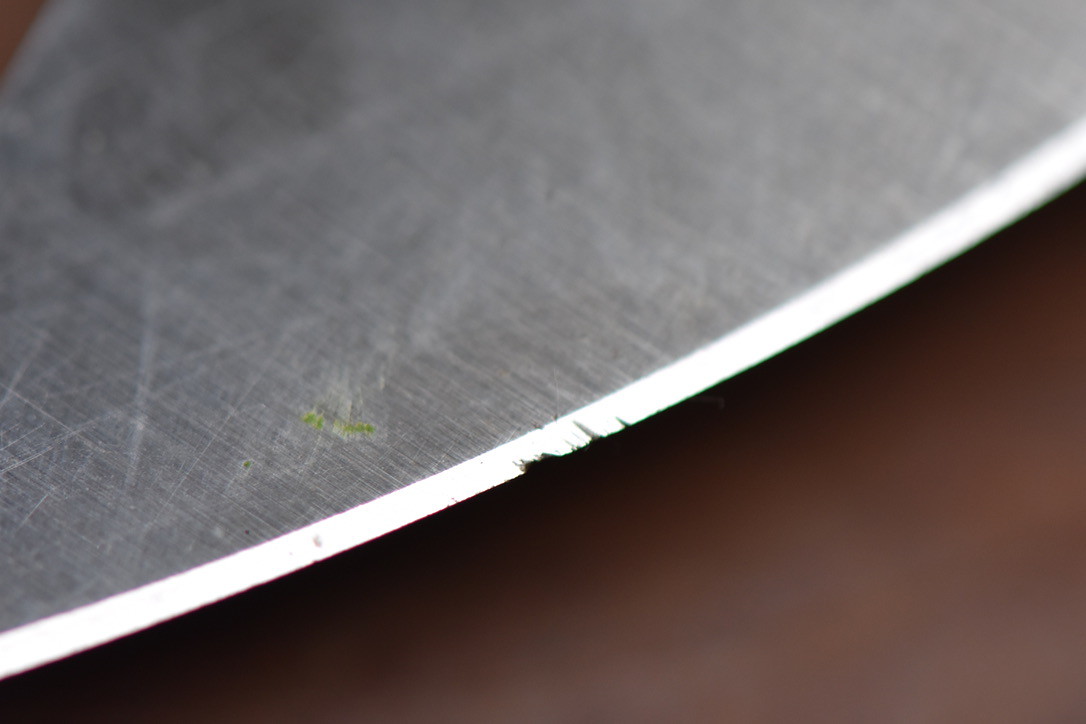

Here's a shot of the A8(mod) blade <60 Rc that chipped, but also cracked along what seems to be (although I really don't know for sure) poor grain direction.

Gently increase the secondary bevel by 5 degrees. Try that, if it's still chipping maybe add more thickness behind the edge. Then add another 5 degrees, until the edge is strong and stable.

It's difficult to tell by the picture, how acute of the secondary angle is it? Looks thin.