-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Airliner axe

- Thread starter Steve Tall

- Start date

- Joined

- Aug 28, 2010

- Messages

- 5,431

"Shortly after taking off from Atlanta on a flight to Gulfport, the aircraft experienced propeller separation in the left engine while climbing through FL 180. The aircraft hit trees, crashed into a field and burned while trying to make an emergency landing at West Georgia Regional Airport."

photo and quote from http://www.planecrashinfo.com/w19950821.htm

- Joined

- Aug 21, 2013

- Messages

- 3,898

Wikipedia gives some more details about the axe used after the 1995 plane crash in Georgia:

"Despite a dislocated shoulder, First Officer Warmerdam used the cockpit fire axe to cut through the thick cockpit glass. David McCorkell, a surviving passenger, later assisted by pulling the axe out of the cockpit through the hole Warmerdam had created and struck the glass from the outside in order to increase the size of the hole and help Warmerdam escape... The emergency crews successfully pulled Warmerdam out of the aircraft."

He wanted out. Right tool, right time, right context.

- Joined

- Aug 28, 2010

- Messages

- 5,431

He wanted out. Right tool, right time, right context.

There was a TV show that re-created the crash story, and starting at 25:35 in this (low quality) video, the surviving first officer describes his ordeal with the axe (actually a hatchet). In this retelling, the head of the hatchet eventually flies off the handle during the chopping of the window.

In Ottawa back in the 1960s National Research Council of Canada built a chicken gun to simulate bird strikes on aircraft. The very long barrelled compressed air cannon launched specific weight chickens at close to the speed of sound. Forward windscreen glass was discovered to be particularly vulnerable and manufacturers have had to beef these up ever since. The primary reason SWAT forces maintain 50 BMG scoped rifles now is they're one of the very few rounds that can reliably penetrate modern aircraft cockpit glass.They should not only require the proper equipment but they should require egress training. I can see why one would THINK the glass was the fastest route.........

You'd want to be fueled by a lot of adrenaline when figuring on chopping out airliner front glass with a hatchet!

- Joined

- Nov 7, 2016

- Messages

- 796

Just another example of how knowledge and a little hands on life experience would allow one to work smarter. Instead of flailing about like a buffoon. It is amazing that when they decided they needed an ax to escape.......and that a small amount of people would have access.........they did not also come to the conclusion they might need a brief or two.You'd want to be fueled by a lot of adrenaline when figuring on chopping out airliner front glass with a hatchet!

- Joined

- Aug 28, 2010

- Messages

- 5,431

Found some interesting details about that crash:

The ax (hatchet) handle was wood, about 14" long. The ax had "a single blade with a nail-puller notch, and the opposite end of the blade had a shape that was similar to a hammerhead." The first officer chopped only a 4" diameter hole in the center of the "hardened plexiglass" side window, then handed the ax through the hole to a passenger, who tried to chop a big enough hole. When the sheriff arrived at the scene, he saw the passenger striking the window with the ax. "The wooden handle separated from the ax head early in the rescue effort. About 2 minutes after the ax handle broke, the local fire department arrived and tried, unsuccessfully to break the window using full size axes."

The first officer was rescued through the cockpit doorway, not the window. "In the following several minutes, the fire aft of the cockpit was controlled sufficiently to allow firefighters to enter the cabin and break through the cockpit door to rescue the first officer."

In 1995 (the year of the crash), even though "there [was] no FAA or other civil technical standard regarding the design and use of crash axes", "the crash ax carried aboard military transport aircraft conforms to a special design" and "large commercial transport airplanes manufactured in the United States are equipped with crash axes of similar design." (The Embraer aircraft that crashed was presumably made in Brazil, not the USA).

from Official Accident Report,

ATLANTIC SOUTHEAST AIRLINES, INC., FLIGHT 529

EMBRAER EMB-120RT, N256AS CARROLLTON, GEORGIA

AUGUST 21, 1995

Regarding the crash axe standards that were developed in response to this crash (published by the SAE in 2001), it looks like the crash axe standards were never actually made part of the regulations:

"...the FAA indicated that it had requested the Society of Automotive Engineers (SAE) to develop an Aerospace Standard for aircraft crash axes. In 2001, the SAE published an Aerospace Information Report, with an associated Aerospace Standard and an Aerospace Recommended Practice. The FAA also reported that it had originally intended to issue an advisory circular promulgating the standard; however, the FAA's review of the wording in the applicable regulations indicated this was not permissible because the regulations only specified that a crash ax must be provided, not that the design or installation must be approved by the FAA. The Safety Board believes that, in view of the development of the Aerospace Information Report, Standard, and Recommended Practice, the FAA has met the intent of this recommendation in an acceptable alternate manner. Accordingly, Safety Recommendation A-96-149 is classified "Closed--Acceptable Alternate Action."

quoted from NTSB Safety Recommendation History, 12/04/2003

The ax (hatchet) handle was wood, about 14" long. The ax had "a single blade with a nail-puller notch, and the opposite end of the blade had a shape that was similar to a hammerhead." The first officer chopped only a 4" diameter hole in the center of the "hardened plexiglass" side window, then handed the ax through the hole to a passenger, who tried to chop a big enough hole. When the sheriff arrived at the scene, he saw the passenger striking the window with the ax. "The wooden handle separated from the ax head early in the rescue effort. About 2 minutes after the ax handle broke, the local fire department arrived and tried, unsuccessfully to break the window using full size axes."

The first officer was rescued through the cockpit doorway, not the window. "In the following several minutes, the fire aft of the cockpit was controlled sufficiently to allow firefighters to enter the cabin and break through the cockpit door to rescue the first officer."

In 1995 (the year of the crash), even though "there [was] no FAA or other civil technical standard regarding the design and use of crash axes", "the crash ax carried aboard military transport aircraft conforms to a special design" and "large commercial transport airplanes manufactured in the United States are equipped with crash axes of similar design." (The Embraer aircraft that crashed was presumably made in Brazil, not the USA).

from Official Accident Report,

ATLANTIC SOUTHEAST AIRLINES, INC., FLIGHT 529

EMBRAER EMB-120RT, N256AS CARROLLTON, GEORGIA

AUGUST 21, 1995

Regarding the crash axe standards that were developed in response to this crash (published by the SAE in 2001), it looks like the crash axe standards were never actually made part of the regulations:

"...the FAA indicated that it had requested the Society of Automotive Engineers (SAE) to develop an Aerospace Standard for aircraft crash axes. In 2001, the SAE published an Aerospace Information Report, with an associated Aerospace Standard and an Aerospace Recommended Practice. The FAA also reported that it had originally intended to issue an advisory circular promulgating the standard; however, the FAA's review of the wording in the applicable regulations indicated this was not permissible because the regulations only specified that a crash ax must be provided, not that the design or installation must be approved by the FAA. The Safety Board believes that, in view of the development of the Aerospace Information Report, Standard, and Recommended Practice, the FAA has met the intent of this recommendation in an acceptable alternate manner. Accordingly, Safety Recommendation A-96-149 is classified "Closed--Acceptable Alternate Action."

quoted from NTSB Safety Recommendation History, 12/04/2003

- Joined

- Aug 28, 2010

- Messages

- 5,431

"This SAE Aerospace Recommended Practice (ARP) recommends general criteria for availability, location, accessibility, stowage, use, and crew member training needed for aircraft crash axes.":

SAE Standard ARP5403A

http://standards.sae.org/arp5403a/

SAE Standard ARP5403A

http://standards.sae.org/arp5403a/

- Joined

- Aug 28, 2010

- Messages

- 5,431

The report said that the sliding side window was jammed by the crash impact, and if the axe had a prybar function, then perhaps the first officer would have been able to pry it open. During the investigation of the crash, prybars were successfully used to unjam and open the sliding window.

- Joined

- Nov 7, 2016

- Messages

- 796

Yeah, there really is not much room in those puppies. The recommended cut out zones for rescue are usually overhead. 11 and 1 and whatnot. There is not much room for anything that might give you enough humph to bust out. Sounds like a more coordinated effort to make sure that window can be opened with multiple failsafes perhaps multiple sliding windows and prybars........The report said that the sliding side window was jammed by the crash impact, and if the axe had a prybar function, then perhaps the first officer would have been able to pry it open. During the investigation of the crash, prybars were successfully used to unjam and open the sliding window.

Seems like as much as I love axes, in this case it really just is not the answer.

- Joined

- Apr 12, 2006

- Messages

- 2,506

Interesting. I've been in the slow process of developing a new family of more specialized tomahawks in addition to my original three more generalized designs, and it includes a rescue ax based in part on the crash ax design. Here's the current prototype, which will be seeing some tweaks.

It's designed with cutting through wrecked vehicles in mind (aircraft or otherwise), so part of that means no beard to hang up in the sheet metal. Prybar on the end, and a slightly different spike design than the one here pictured, designed to easily slip into an average padlock shackle so that leverage can be used to break them open.

The bevels show up better in this pre-heat treatment pic. The spike bevels hadn't been ground yet.

It's intended as a rescue ax and not necessarily a straight-up "crash ax" that lives its life on a plane, so I turned the real estate of the lightening hole into a fire hydrant/residential gas valve wrench.

Or, what do I know? I could be dishonestly misrepresenting a billhook as an ax.

It's designed with cutting through wrecked vehicles in mind (aircraft or otherwise), so part of that means no beard to hang up in the sheet metal. Prybar on the end, and a slightly different spike design than the one here pictured, designed to easily slip into an average padlock shackle so that leverage can be used to break them open.

The bevels show up better in this pre-heat treatment pic. The spike bevels hadn't been ground yet.

It's intended as a rescue ax and not necessarily a straight-up "crash ax" that lives its life on a plane, so I turned the real estate of the lightening hole into a fire hydrant/residential gas valve wrench.

Or, what do I know? I could be dishonestly misrepresenting a billhook as an ax.

- Joined

- Mar 15, 2016

- Messages

- 712

I take it that tool is for clearing the brush around a wreck so that the rescuers can access the vehicle

Storm Crow

Seriously though that latest iteration looks awesome!

Storm Crow

Seriously though that latest iteration looks awesome!

David Martin

Moderator

- Joined

- Apr 7, 2008

- Messages

- 19,520

Steve, you come up with the most interesting topics. Glad your here. DM

- Joined

- Aug 21, 2013

- Messages

- 3,898

Steve, you come up with the most interesting topics. Glad your here. DM

Agreed.

All I keep thinking about is having to use an axe to escape a plane's cockpit...

- Joined

- Aug 28, 2010

- Messages

- 5,431

Thanks for the kind words, gents.

From a U.S. Navy manual on Aircraft Emergency Rescue, an unusual axe design, and one approach that involves pulling out the window gasket before pushing in the window:

from https://www.scribd.com/document/474...y-Rescue-Most-all-aircraft-and-ejection-seats

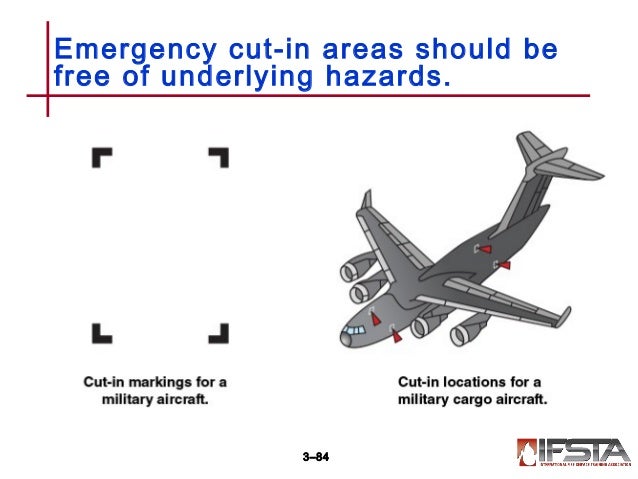

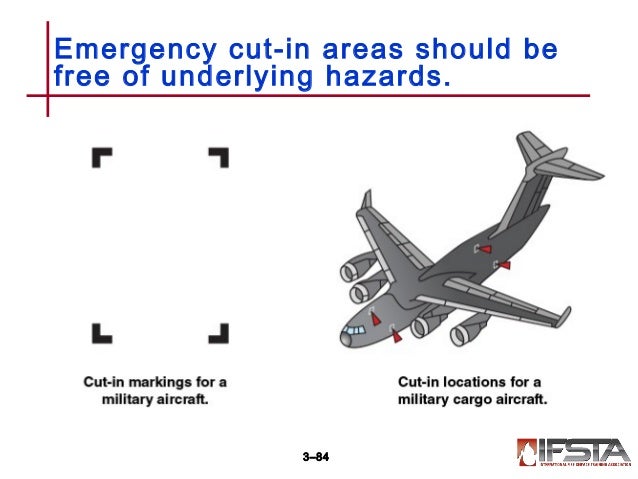

Examples of the cut-in markings on military aircraft:

From a U.S. Navy manual on Aircraft Emergency Rescue, an unusual axe design, and one approach that involves pulling out the window gasket before pushing in the window:

from https://www.scribd.com/document/474...y-Rescue-Most-all-aircraft-and-ejection-seats

Examples of the cut-in markings on military aircraft: