I have one like this from their competitor, Cleveland Quarries (CQ). I thought it was older until I found the patent dated 1940:

Some information from an earlier thread:

This grindstone is made of "Berea Sandstone" from Ohio. "Berea Sandstone is an excellent building stone due to the composition of grains of Quartz bonded by Silica. The extreme hardness of the Quartz grains of Berea Sandstone enables it to preserve an abrasive non-slip surface... The silica bond does not deteriorate with time, exposure to water or temperature change and so prolongs to longevity of the stone."

from

http://www.clevelandquarries.com/technical-data

Cleveland Quarries Company was formed in

1929, consolidating the operations of two other companies.

In the

1940s, Cleveland Quarries sold household grindstones through its Berea Abrasives division, with many model including:

The Harvester

The Streamliner

The Sterling

The Norka

The

Bi-Treadle

The Harvest King

The Eureka

The Samson

The Little Giant

The Hercules

The Keystone

The Shipstone

The Family Grindstone

Up until the unsuccessful Bay of Pigs invasion of Cuba in

1961, Cuba had been one of the largest importers of grindstones, and after the trade embargo, the Cleveland Quarries Company's grindstone business suffered. "...most agree that

the [sandstone grindstone] industry died in the 1960s."

Source:

Sandstone Center of the World, by James A. Hieb, 2007

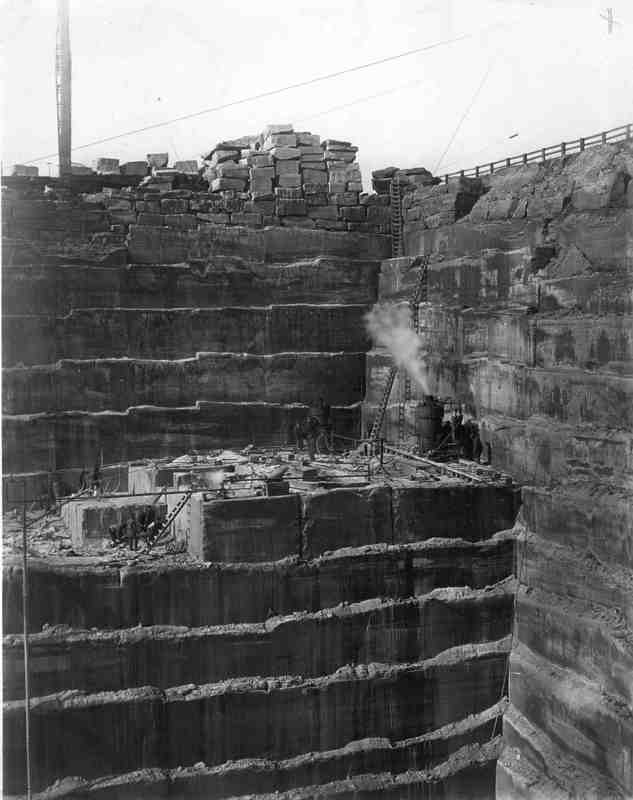

"This image from 1921 shows the scale of Quarry No. 7. Workers get to their workstation via ladders. Stacks of stone already cut from the quarry can be seen on the top left."

text and photo from ClevelandHistorical.org

https://clevelandhistorical.org/files/show/2241#.WYugplWGPIU