The conversion is not black and white, which is why the different conversion sheets don't agree with each other. There are so many variables besides the size of the abrasive that the vagueness doesn't matter.

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone hear of Dr. Marv and his resin bond diamond stones?

- Thread starter Diemaker

- Start date

- Joined

- Mar 8, 2008

- Messages

- 26,169

Yeah, this. The difference in abrasive grit rating standards uses different tolerances and permissible min/max grain size, weighted average grain size, and so on, and each standard uses different parameters. But grain size is only one of many variables affecting performance, to the point where there isn't really a truly simple, singular metric to use for it.

It is also important to understand that one stone can have different results on the same steel depending on how you dress it.

My new PDT CBN stones ground like a new, insanely scratched mirror, even after a 15,000 grid (1/0 micron) grit.

But I adjusted them by dripping industrial diamond slurry with a grain size of 0.25-0.5 microns onto them and grinding two stones (15,000 and 10,000) against each other for about a minute. Then I washed the stones and dressed them again under running water with Naniwa 12000 nagura just to remove any loose grain residue on the surface.

Now the stones sharpen so that only a few hairline scratches are visible on the entire blade, which can only be seen at the right angle of light.

However, it is still not the same result as with Dr. Marv stones in terms of the mirror finish on the edge.

Of course, there is always room for improvement. I know this because I work in the optical industry, where we grind tungsten carbide to tolerances below 10 nanometers, which is also a mirror, but it seems unnatural to the human eye. It no longer looks like a mirror, but rather a window into another dimension.

I would like to ask the moderator how many posts I need to make on this forum before I am allowed to post images?

My new PDT CBN stones ground like a new, insanely scratched mirror, even after a 15,000 grid (1/0 micron) grit.

But I adjusted them by dripping industrial diamond slurry with a grain size of 0.25-0.5 microns onto them and grinding two stones (15,000 and 10,000) against each other for about a minute. Then I washed the stones and dressed them again under running water with Naniwa 12000 nagura just to remove any loose grain residue on the surface.

Now the stones sharpen so that only a few hairline scratches are visible on the entire blade, which can only be seen at the right angle of light.

However, it is still not the same result as with Dr. Marv stones in terms of the mirror finish on the edge.

Of course, there is always room for improvement. I know this because I work in the optical industry, where we grind tungsten carbide to tolerances below 10 nanometers, which is also a mirror, but it seems unnatural to the human eye. It no longer looks like a mirror, but rather a window into another dimension.

I would like to ask the moderator how many posts I need to make on this forum before I am allowed to post images?

- Joined

- Mar 8, 2008

- Messages

- 26,169

With an unpaid account, images have to be hosted on another website and IMG tags used to reference the URL.It is also important to understand that one stone can have different results on the same steel depending on how you dress it.

My new PDT CBN stones ground like a new, insanely scratched mirror, even after a 15,000 grid (1/0 micron) grit.

But I adjusted them by dripping industrial diamond slurry with a grain size of 0.25-0.5 microns onto them and grinding two stones (15,000 and 10,000) against each other for about a minute. Then I washed the stones and dressed them again under running water with Naniwa 12000 nagura just to remove any loose grain residue on the surface.

Now the stones sharpen so that only a few hairline scratches are visible on the entire blade, which can only be seen at the right angle of light.

However, it is still not the same result as with Dr. Marv stones in terms of the mirror finish on the edge.

Of course, there is always room for improvement. I know this because I work in the optical industry, where we grind tungsten carbide to tolerances below 10 nanometers, which is also a mirror, but it seems unnatural to the human eye. It no longer looks like a mirror, but rather a window into another dimension.

I would like to ask the moderator how many posts I need to make on this forum before I am allowed to post images?

I will also show the results of experiments using Dr. Marv 0.5 micron stone. After 1 micron stone, it is practically impossible to use. Both surfaces rubbing against each other are so smooth that a phenomenon called adhesion occurs and the diamond tears pieces of material out of the steel.

So I tried to roughen the 0.5 stone using an electroplated 80-grit plate, but without success.

So I tried leaving the rough edge surface and, after 10-micron grit, I immediately ground it with a 0.5-micron Dr. Marv stone.

The result is absolutely fantastic sharpness.

Better than after the entire sequence of stones from 10 microns to 1 micron.

To give you an idea, a colleague of mine gave me one of her hairs. I dropped it on the blade and it got stuck on the edge. When I blew on it, it cut through.

S35VN

So I tried to roughen the 0.5 stone using an electroplated 80-grit plate, but without success.

So I tried leaving the rough edge surface and, after 10-micron grit, I immediately ground it with a 0.5-micron Dr. Marv stone.

The result is absolutely fantastic sharpness.

Better than after the entire sequence of stones from 10 microns to 1 micron.

To give you an idea, a colleague of mine gave me one of her hairs. I dropped it on the blade and it got stuck on the edge. When I blew on it, it cut through.

S35VN

dantzk8

Basic Member

- Joined

- Nov 1, 2005

- Messages

- 1,951

While I fully understand that this site owes its long standing existence to the steady diet of threads titled “Which fixed blade to baton through the crankshaft of my small block Chevy engine?”, it’s the discussions like this one that have kept me a huge fan of Bladeforums for over a quarter century. Pushing the limits of our sharpening abilities is a never ending pursuit, but ultimately a fun and rewarding one. Thanks to D Diemaker and B -BaRD- for generously sharing your time and wealth of information.

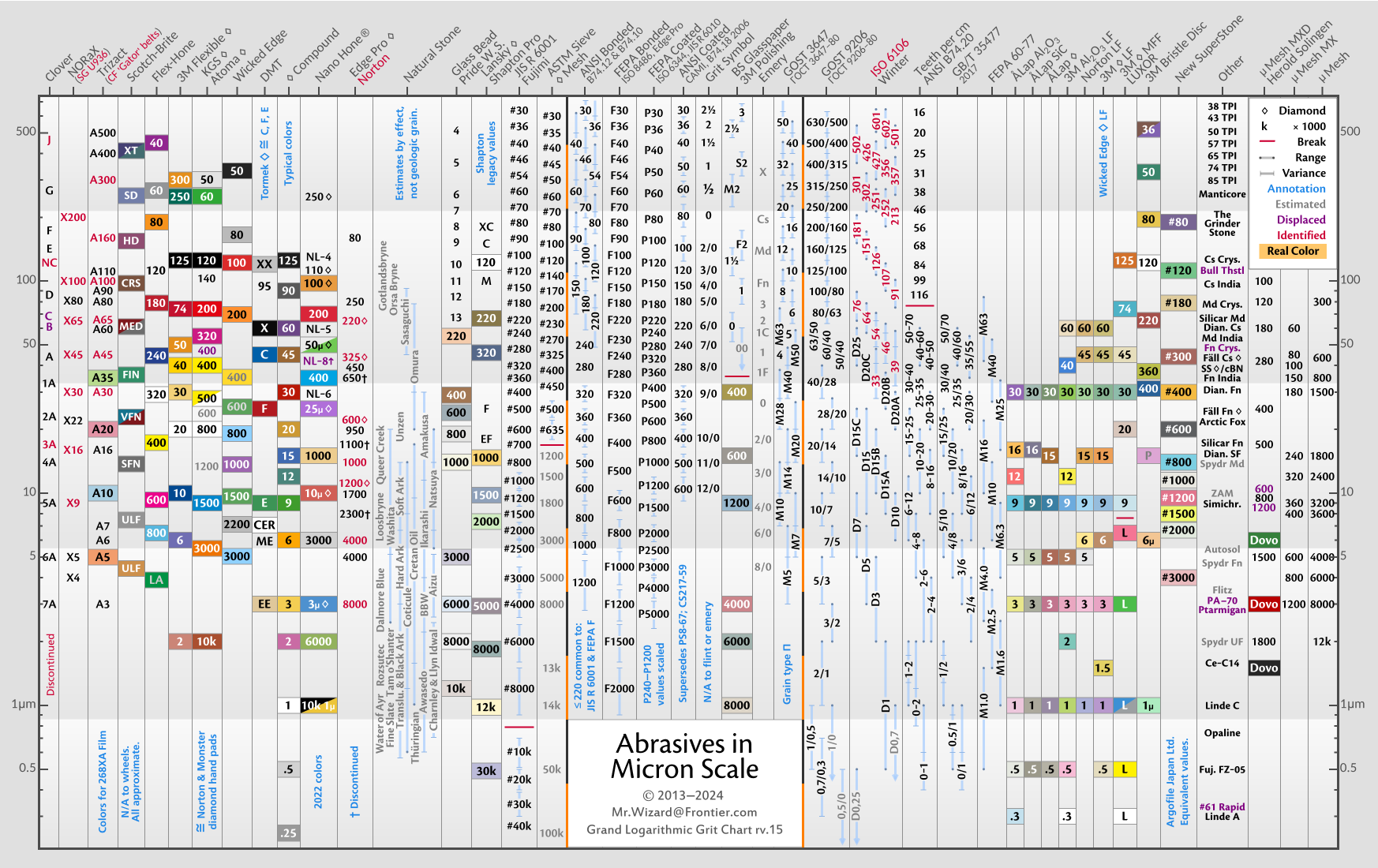

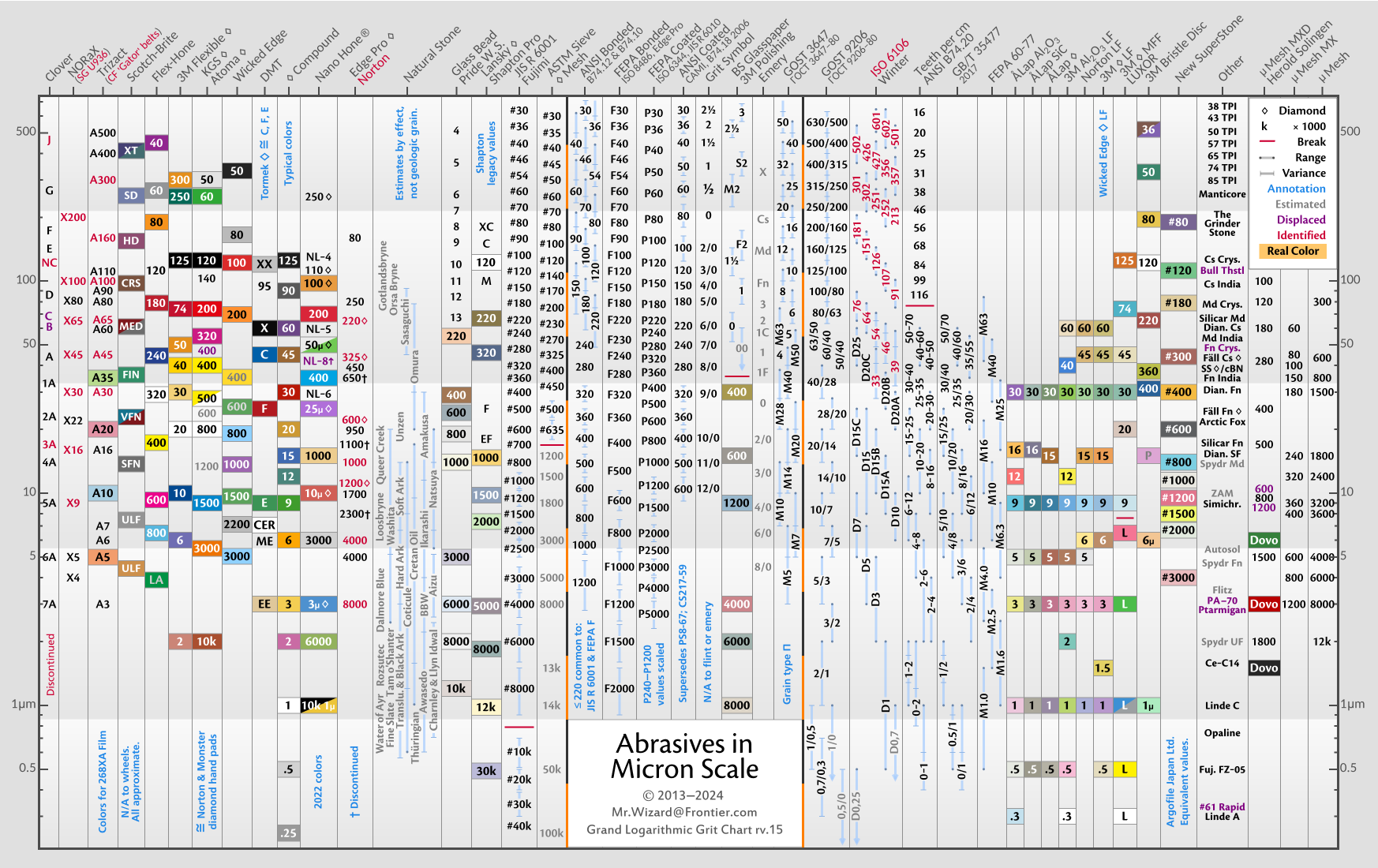

Is there one chart out there you guys would recommend as the most accurate for converting micron size to grit values, in the specific context of blade sharpening, at least? A quick Google search will reveal thousands of such charts, but the discrepancies from one to the next can be truly monumental.

I would recommend this one:

Revision 16 is live. See the README for details and license. Feel free to comment on style or content, and please let me know if you find any errors. The previous revision resides at https://myplace.frontier.com/~mr.wizard/GLGC/ for visual comparison. I am embedding in WebP format below for a smaller file size; if does not appear please try the PNG version: https://myplace.frontier.com/~mr.wizard/GLGC/GLGC.png

https://myplace.frontier.com/~mr.wizard/GLGC/README.txt

https://myplace.frontier.com/~mr.wizard/GLGC/README.txt

- Mr.Wizard

- Replies: 9

- Forum: Maintenance, Tinkering & Embellishment

Dan.

Bronco

Moderator

- Joined

- Feb 25, 2000

- Messages

- 7,601

I will also show the results of experiments using Dr. Marv 0.5 micron stone. After 1 micron stone, it is practically impossible to use. Both surfaces rubbing against each other are so smooth that a phenomenon called adhesion occurs and the diamond tears pieces of material out of the steel.

So I tried to roughen the 0.5 stone using an electroplated 80-grit plate, but without success.

So I tried leaving the rough edge surface and, after 10-micron grit, I immediately ground it with a 0.5-micron Dr. Marv stone.

The result is absolutely fantastic sharpness.

Better than after the entire sequence of stones from 10 microns to 1 micron.

To give you an idea, a colleague of mine gave me one of her hairs. I dropped it on the blade and it got stuck on the edge. When I blew on it, it cut through.

S35VN

View attachment 3032514

What an inspired thought to try going straight from 10 micron to .5 micron - and what an amazing result has emerged. Well done. It would seem as if the .5 micron stone at this point more or less becomes the world’s ultimate strop - with the added advantage of knowing that this “strop” is perfecting your apex at the exact same angle as all your other stones.

Approximately how many passes on each side would you guess are optimal with the .5 micron stone in this direct 10 micron to .5 micron progression? And can I assume you’re using not much more pressure on the .5 micron stone than basically the weight of the stone itself?

Finally, is it your technique to run the sharpening strokes by pushing the .5 micron stone into the edge apex or pulling away from it?

Last edited:

Bronco

Moderator

- Joined

- Feb 25, 2000

- Messages

- 7,601

I neglected to mention that I pulled the trigger on a set of Dr. Marv’s medium grit set of stones. The family wants them to be my Christmas present this year, so they’ll be sitting in a nicely wrapped box for a while before I actually get to use them.  The international shipping via DHL was extremely fast and uneventful.

The international shipping via DHL was extremely fast and uneventful.

The occasion of making the purchase did give me the opportunity to engage in an exceedingly pleasant email exchange with Dr. Marv himself during which he was gracious enough to answer a few of my questions.

As for dressing his stones, it sounds as if this is a task that will need to be undertaken infrequently at most. He’s been working cooperatively with some local German makers who craft blades in high hardness/high wear resistance steels like Rex 121, Vanadis 8 and Nitrobe. They’ve been using his stones for almost a year now, and reportedly have not yet needed to do any flattening. That said, if/when you eventually get to the point where you’re beginning to experience some slight dishing, the remedy is pretty easy and straightforward. Dr. Marv recommends gently dressing the stones with an Atoma F400 diamond plate under a constant flow of lukewarm water. He also recommends that, before using the Atoma plate in this capacity for the first time, you give it a vigorous rub down all over its surface with an old knife or annealed (ideally) steel rod, again under running water, ensuring that it’s fully cleaned before using it on his stones. He’s generally pleased with the quality and purity of the Atoma plates, but this quick precaution will provide an extra measure of security to ensure that his stones aren’t cross contaminated.

He says his stones can be used with water, but that you’ll get greatly improved performance by using a water soluble lapping oil such as is available from Hapstone. He also mentioned an Oelheld branded water soluble stamp and die oil that he says is an order of magnitude even better than that, but isn’t sold in the U.S. in quantities less than 5 gallons.

The occasion of making the purchase did give me the opportunity to engage in an exceedingly pleasant email exchange with Dr. Marv himself during which he was gracious enough to answer a few of my questions.

As for dressing his stones, it sounds as if this is a task that will need to be undertaken infrequently at most. He’s been working cooperatively with some local German makers who craft blades in high hardness/high wear resistance steels like Rex 121, Vanadis 8 and Nitrobe. They’ve been using his stones for almost a year now, and reportedly have not yet needed to do any flattening. That said, if/when you eventually get to the point where you’re beginning to experience some slight dishing, the remedy is pretty easy and straightforward. Dr. Marv recommends gently dressing the stones with an Atoma F400 diamond plate under a constant flow of lukewarm water. He also recommends that, before using the Atoma plate in this capacity for the first time, you give it a vigorous rub down all over its surface with an old knife or annealed (ideally) steel rod, again under running water, ensuring that it’s fully cleaned before using it on his stones. He’s generally pleased with the quality and purity of the Atoma plates, but this quick precaution will provide an extra measure of security to ensure that his stones aren’t cross contaminated.

He says his stones can be used with water, but that you’ll get greatly improved performance by using a water soluble lapping oil such as is available from Hapstone. He also mentioned an Oelheld branded water soluble stamp and die oil that he says is an order of magnitude even better than that, but isn’t sold in the U.S. in quantities less than 5 gallons.

Wow, lots of questions

First of all, I must also praise the communication with Dr. Marv. I ordered a fine set from 2.5 to 0.5 microns for quite a lot of money. I was amazed by the results after using the 2.5 and 1 micron stones, but no matter how hard I tried, I couldn't use the 0.5μm stone without damaging the surface.

I wrote to Dr. Marv to ask if he had any recommendations and if I could exchange the 0.5μm stone for a stone of a different grain size from his production.

He wrote me a few tips on how to use the stone and told me to keep it and that he would send me two more stones "in the hope that I would be satisfied with my purchase."

That completely took my breath away...

His communication and kindness are unparalleled

As for dressing, I used galvanic diamond to dress the stones. They were already completely black because I tried grinding them with clean water or dry grinding, and the stones became heavily clogged with ground metal. It couldn't be removed with alcohol, CO2, or even the rough side of a sponge with detergent.

Dressing the stones was the only way to restore the surface.

I used cheap 80-grit galvanic diamond from China, thinking that even if a grain came loose and remained in the Marv stone, I would see it because of its size and scrape it off.

Before dressing, I lightly sanded the galvanic plate with another galvanic plate of the same grain size under water (some grains fell out) to make sure that the diamond that remained in the plate would actually stick.

However, after processing the stones, Marv began to produce scratches, and under a microscope I discovered that the stone contained large golden-colored diamond grains from galvanic plate.

And so began my effort to dress the stones so that they would grind as well as they did at the beginning. After each dressing, I ground a test blade to see if they were still scratching.

I tried sandpaper of the same grit as the stones, thinking that it would remove the grains from the surface, including the parasitic ones. That didn't work.

So I dressed the stones with nagura Naniwa 12000 grid. That didn't work.

So I made a suspension with 12000 nagura on a hard natural stone Rozsutec and dressed the Marv stones on that suspension. That didn't work.

So I used a diamond suspension of the same grain size as the stones on glass. That didn't work either. Although the result of sharpening the blade with stones dressed in this way was closest to how the stones sharpened at the beginning.

before / after

In the end, I sent them to my sharpening colleague who specializes in sharpening with natural stones and has much more experience with dressing stones.

He used cerium oxide and crushed limestone on a Rozsutec stone.

When the stones arrive home, I will sharpen the blade and share the results.

First of all, I must also praise the communication with Dr. Marv. I ordered a fine set from 2.5 to 0.5 microns for quite a lot of money. I was amazed by the results after using the 2.5 and 1 micron stones, but no matter how hard I tried, I couldn't use the 0.5μm stone without damaging the surface.

I wrote to Dr. Marv to ask if he had any recommendations and if I could exchange the 0.5μm stone for a stone of a different grain size from his production.

He wrote me a few tips on how to use the stone and told me to keep it and that he would send me two more stones "in the hope that I would be satisfied with my purchase."

That completely took my breath away...

His communication and kindness are unparalleled

As for dressing, I used galvanic diamond to dress the stones. They were already completely black because I tried grinding them with clean water or dry grinding, and the stones became heavily clogged with ground metal. It couldn't be removed with alcohol, CO2, or even the rough side of a sponge with detergent.

Dressing the stones was the only way to restore the surface.

I used cheap 80-grit galvanic diamond from China, thinking that even if a grain came loose and remained in the Marv stone, I would see it because of its size and scrape it off.

Before dressing, I lightly sanded the galvanic plate with another galvanic plate of the same grain size under water (some grains fell out) to make sure that the diamond that remained in the plate would actually stick.

However, after processing the stones, Marv began to produce scratches, and under a microscope I discovered that the stone contained large golden-colored diamond grains from galvanic plate.

And so began my effort to dress the stones so that they would grind as well as they did at the beginning. After each dressing, I ground a test blade to see if they were still scratching.

I tried sandpaper of the same grit as the stones, thinking that it would remove the grains from the surface, including the parasitic ones. That didn't work.

So I dressed the stones with nagura Naniwa 12000 grid. That didn't work.

So I made a suspension with 12000 nagura on a hard natural stone Rozsutec and dressed the Marv stones on that suspension. That didn't work.

So I used a diamond suspension of the same grain size as the stones on glass. That didn't work either. Although the result of sharpening the blade with stones dressed in this way was closest to how the stones sharpened at the beginning.

before / after

In the end, I sent them to my sharpening colleague who specializes in sharpening with natural stones and has much more experience with dressing stones.

He used cerium oxide and crushed limestone on a Rozsutec stone.

When the stones arrive home, I will sharpen the blade and share the results.

As for oils, I am thinking of starting a new thread where I will show the results under a microscope with the same stones and steel, but with different oils.

The short version is that the thicker the oil we use, the more the carbides in the steel will protrude above the rest of the steel after grinding.

Also, if we have a protruding parasitic grain in the stone that scratches, after using thick oil, the scratch will be noticeably shallower.

Also, the thicker the oil used on a finer stone, the less effective the stone becomes.

(diamond grains do not penetrate as deeply into the metal)

Where this is significant is in the settling of ground metal in the stones.

I think there is an effect where, during grinding, the metal grain is ground down and then covered with oil, which then does not adhere as well and can be easily wiped off.

The short version is that the thicker the oil we use, the more the carbides in the steel will protrude above the rest of the steel after grinding.

Also, if we have a protruding parasitic grain in the stone that scratches, after using thick oil, the scratch will be noticeably shallower.

Also, the thicker the oil used on a finer stone, the less effective the stone becomes.

(diamond grains do not penetrate as deeply into the metal)

Where this is significant is in the settling of ground metal in the stones.

I think there is an effect where, during grinding, the metal grain is ground down and then covered with oil, which then does not adhere as well and can be easily wiped off.

I would love to see water and dish soap too. I recently compared water and dish soap with a white mineral oil on a softer stainless that loves to form burrs, and at 250x I couldn't tell the difference between the two on burr formation.

777 Edge

Dealer / Materials Provider

- Joined

- Sep 16, 2019

- Messages

- 1,204

Dr. Marv recommends gently dressing the stones with an Atoma F400 diamond plate under a constant flow of lukewarm water. He also recommends that, before using the Atoma plate in this capacity for the first time, you give it a vigorous rub down all over its surface with an old knife or annealed (ideally) steel rod, again under running water, ensuring that it’s fully cleaned before using it on his stones. He’s generally pleased with the quality and purity of the Atoma plates, but this quick precaution will provide an extra measure of security to ensure that his stones aren’t cross contaminated.

From Dr Marv's recommendation to

D Diemaker , your stones are phenomenal quality stones. I wonder if you won't get a very similar level of performance if you try preparing a set the same way as Dr Marv does by being hyper critical about cross contamination. Maybe try preparing a newly made set with a slightly used 400 Atoma plate to see what happens?

Unfortunately, I don't have any plated stones that are not totally worn out. But the idea of using plated diamonds to dress resin bond diamonds does send a shiver down my spine. It will take the points off the plated diamonds. I have yet to detect contamination from dressing and have looked for it in both the stones and scratches on the bevel, so I question if this is an issue. Still, I figure I will try dressing on a plated stone at some point to see what it does. I did find it interesting that Dr. Marvin found that using sandpaper stripped the diamonds from the surface of his stones, which I think does the same for mine due to how well they work after dressing them on sandpaper.From Dr Marv's recommendation toBronco and what B -BaRD- has experienced in trying to condition the stones, I'm wondering if Dr Marv's superior performance mostly lies in how careful he is in preparing the surface of his stones to avoid any and all cross contamination.

D Diemaker , your stones are phenomenal quality stones. I wonder if you won't get a very similar level of performance if you try preparing a set the same way as Dr Marv does by being hyper critical about cross contamination. Maybe try preparing a newly made set with a slightly used 400 Atoma plate to see what happens?

I know my stones are far more aggressive after being dressed and need to be used for at least 40 strokes before settling down, I use them for 100 strokes before doing any testing. If my stones are freshly dressed when tested, as Dr. Marvin did when he tested the 4k Matrix stone, then the scratch pattern will be abnormally coarse. He also uses edge leading strokes only. When he tested the 4k Matrix stone he only got a BESS score of 120, so obviously things were going south in that test as it should be in the 70s, from my experience. Edit: 120 is the high, 70 or less is the low, depending on the details.

I think the difference with Dr. Marv's stones is the resin, as always, so much comes down to the bond. The fact he can get his stones to work with 1 micron diamonds is very impressive, I can only get down to 4. There are many stones that say they use finer than 5 microns but the scratch patterns they leave say different. And after Dr. Marv's reviews of them I think that is explained. Interestingly, it looks like we use the same shape of diamond crystals and perhaps the same sizing as well.

It sounds like he might have a slightly higher concentration of diamond in his stones, which may affect the scratch pattern. I have a set with as much diamond in them as possible that I need to test to see how it affects the scratch pattern. I have tested them to see how much they increased the rate of cut and wear, but not the quality of the surface they left.

Last edited:

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,447

Put a little oil on the stone and the diamonds become much more visible. Also, taking photos on the side of the stone where it isn't dressed work quite well.

BaRD, how did your attempts at dressing go? Did you figure out a way to dress them to your satisfaction? One thought I have is to use a softer aluminum oxide to dress with, maybe 2-3 times the size of the abrasive in the stone, so if some becomes embedded in the stone it will come out with a little use and do little to a hard steel.

BaRD, how did your attempts at dressing go? Did you figure out a way to dress them to your satisfaction? One thought I have is to use a softer aluminum oxide to dress with, maybe 2-3 times the size of the abrasive in the stone, so if some becomes embedded in the stone it will come out with a little use and do little to a hard steel.

Last edited:

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,447

Difficult to see the diamonds at 1μm and 0.5μm. Do you have analysis software from work?