Yes a good round knife should be out of very thin stock. I used (I don't make them any more, the beachs kept trying to jump off the grinder and bite me), .040 stock (AEB-L at 62-63 RC). I think the handle orientation of the ulu would make it difficult to use well, besides their thickness.

Honestly the roundknife is one tool that is never put away on my bench. Usually two out there so I don't have to walk around the bench to get one. All sheath, holster, rifle scabbard, basically veg tan work is done with a roundknife. I used some of the inexpensive (Osborne) ones for many years and spent more time sharpening than cutting. Now I spend way more time cutting than sharpening. I bet ya I put my round knives on a stone once every six months or so. I buff/strop the edge often though and that is one of the great advantages of AEB-L steel. Buffing/stropping the edge will bring it right back to hairsplitting. I will buff when the knife first starts to drag or it doesn't cleanly cut in one pass and I have to go back cause it only cut through 7/8s of the leather, I"ll take the 30-45 seconds to touch er up and away we go. Don't let em get dull and they go and go and go.

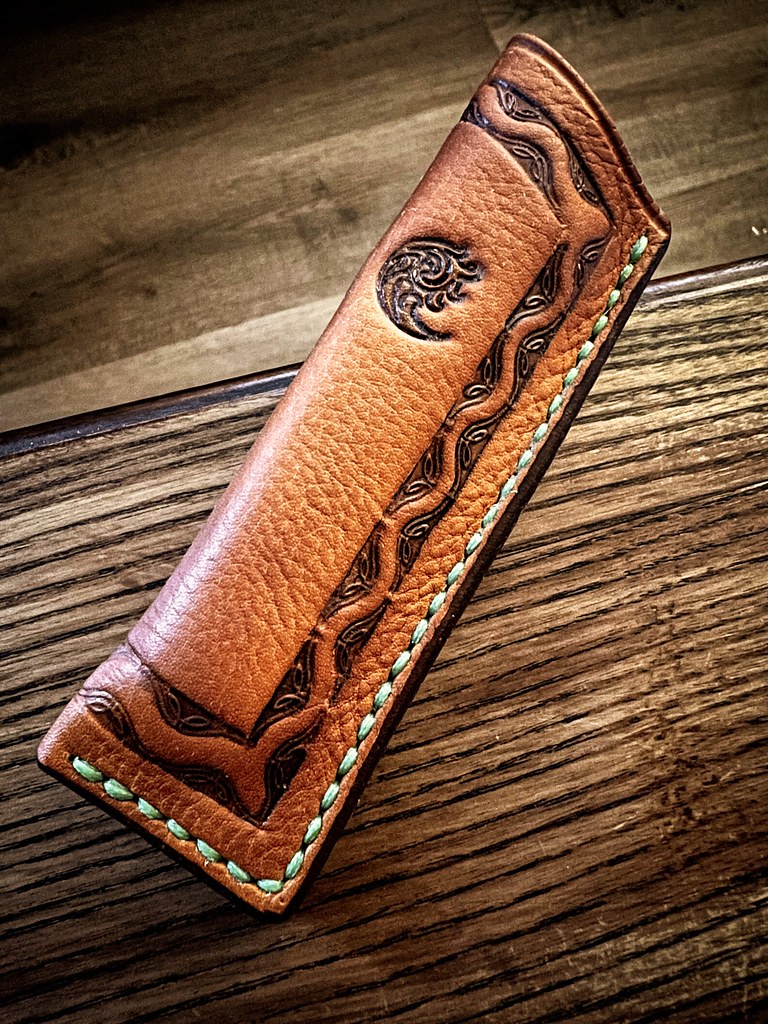

A straight blade with a chisel grind is often called a cut off knife in leather work. They're handy for cutting straight lines against a straight edge. I don't have or use one. I did build one, hated it and now its a shop knife for breaking down cardboard, opening packages etc at which it excels. If I'm cutting leather in a straight line against a straight edge. I use a large roller knife. Built 15 sheaths yesterday, they're on the counter this morning drying overnight after coming out of the oven and being oiled. Looked like this:

Round knife and a roller knife. Don't recall why the roller knife was on that side of the bench as it usually lives on the other side. oh yeah I'd been cutting strings for the knives in the box.

www.bladeforums.com

www.bladeforums.com

www.bladeforums.com

www.bladeforums.com