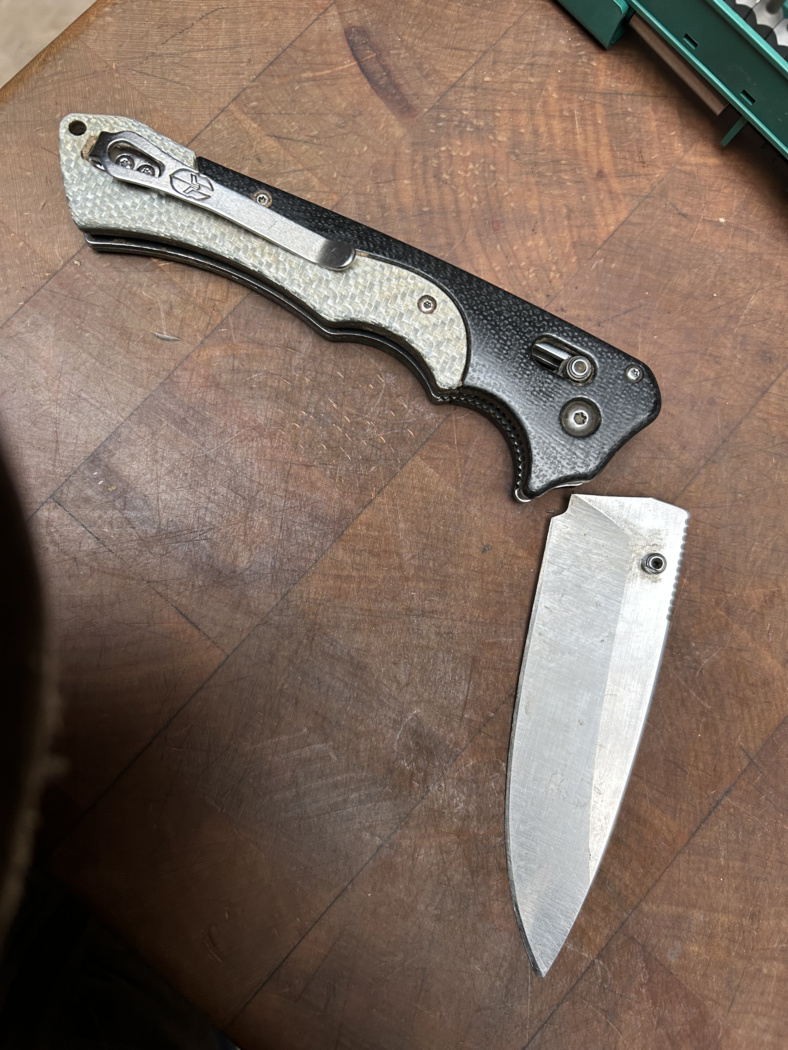

Here it in in better days:

This was a Rukus with a reblade in Vanax SuperClean steel, professionally heat treated by Peters to 60 Rc. It's a homesteading knife that I have used hard for years -- day after day. The edge was ground to 15 thousandths by Josh, and the edge angle is 15 dps. Cuts like a laser. Holds a great edge, never chips, never rolls, even with heavy chopping of branches that has destroyed other blade steels. It's big -- 4.25 inches of blade -- and has a long handle, which gives a lot of leverage. Love this knife. Best knife I have ever had -- by far.

So, yes, I was using it to pry. But gently. I was taking my mower back from annual servicing, and the handle is a bear to reconnect, mostly because of a lot of sharp edges that grab the fingers. So I used the Rukus to gently pry out a handle piece, being very conscious of not putting on too much pressure on the blade. Snap. Hardly any pressure. I don't get it.

The heat treat had to be spot on because this blade has been used so hard for so long with excellent performance.

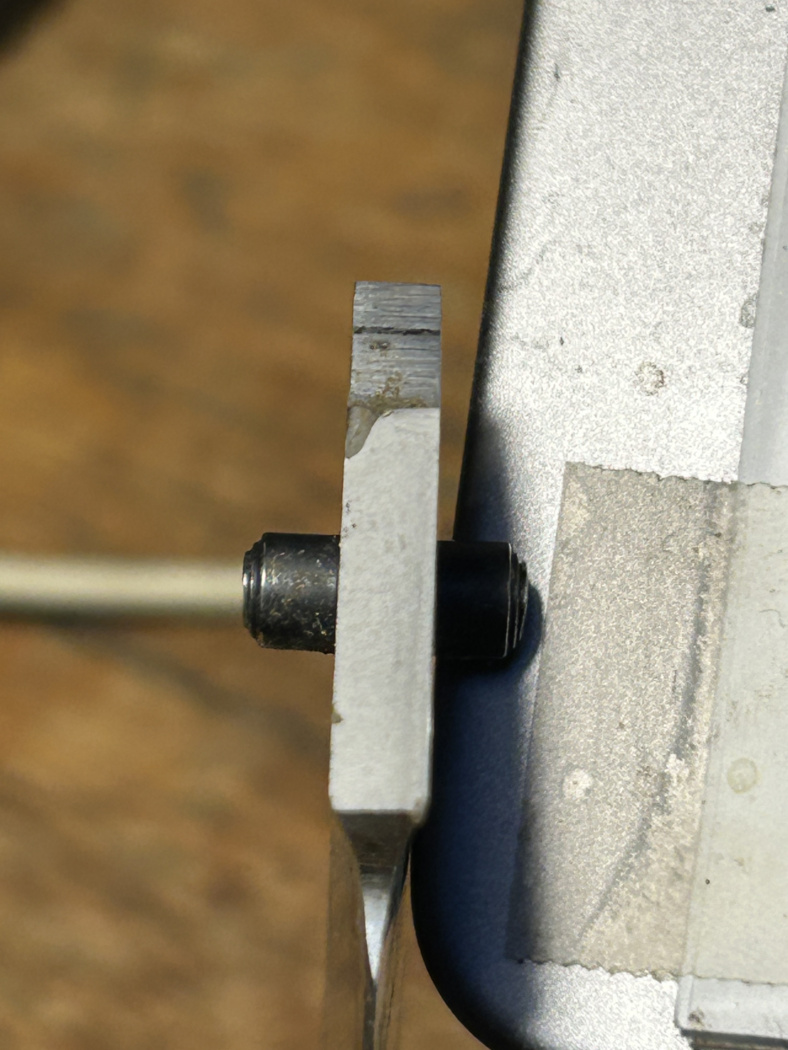

The photos below are of the break. There are what look like inclusions and ripples and a chip off the chip and the grain has different kinds of coloring. I'm thinking the blade steel had some flaws. But I don't really know. I'm grieving.