No no. All good. Mostly, I'm just trying to understand what happened. Probably my fault, but maybe not. I need my knife to handle hard tasks.

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Broke my all time favorite knife (whimper)

- Thread starter Twindog

- Start date

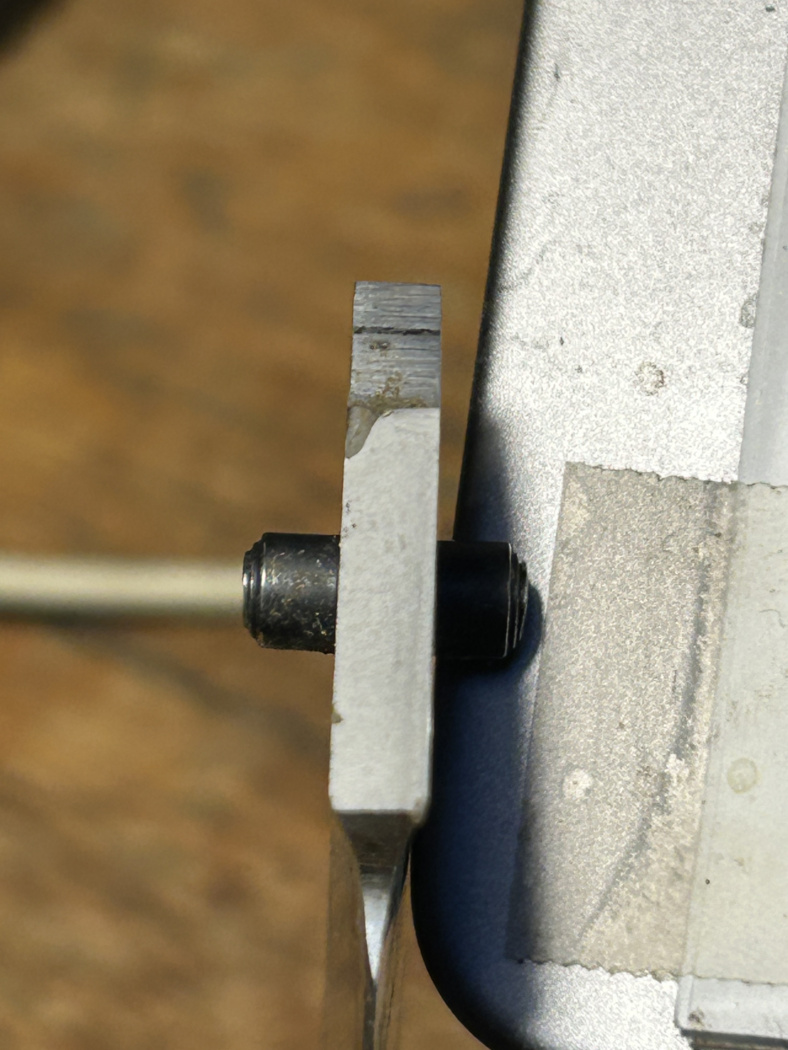

Good point. But it is still the thickest part of the blade. There is a near right angle there, so you're making a good point.Looking at the pictures again and it does seem like it broke at a stress riser. Seems like that is right where the cutout for lock is located.

- Joined

- May 14, 2012

- Messages

- 12,623

It could also have been stress over time. And this last light pry just broke the camel’s back so to speak.No no. All good. Mostly, I'm just trying to understand what happened. Probably my fault, but maybe not. I need my knife to handle hard tasks.

Good news though…it’s either reblade or knife shopping time for you!

I dug out my old Spyderco Military in BG42 and CF scales. It's a 4-inch blade, but a way different knife. Thin and rock solid. When the lock engages, it's like a rifle shot. Sal outdid himself with that one.It could also have been stress over time. And this last light pry just broke the camel’s back so to speak.

Good news though…it’s either reblade or knife shopping time for you!

AntDog

Basic Member

- Joined

- Apr 3, 2001

- Messages

- 27,691

Definitely don’t pry anything with that one.I dug out my old Spyderco Military in BG42 and CF scales. It's a 4-inch blade, but a way different knife. Thin and rock solid. When the lock engages, it's like a rifle shot. Sal outdid himself with that one.

- Joined

- Jul 30, 2006

- Messages

- 44,644

I likewise would guess at some sort of crack which has been there for some time, and the blade finally gave.From the discoloration I'd say there was some.kind of crack there and father time and some corrosion did the rest...

- Joined

- Aug 20, 2022

- Messages

- 1,548

A broke knife. A lost knife. A stolen knife. Tied for first place in things I don't like about this hobby.

- Joined

- Dec 5, 2005

- Messages

- 28,483

I feel your pain- been there myself many a time. So many damaged and broken knives- some real nice customs, too!

One thing that comes to mind reading your thread- well, I deal with people's broken stuff all the time; mountain bikers mainly. In my business, JRA is a ubiquitous expression and draws a knowing nod from anyone in the know. I have heard, more times than I can recall, that phrase which the acronym applies to, used by folks who are bewildered that their bike suddenly broke.

"nothing happened! I can't believe my bike broke! I was just riding along!..."

"yeah, but like, what kind of things have you done with your bike since you've had it?"

cue rapid memory access- eyes flickering as each badly landed drop, cased jump or yard sale is accessed from the ole gray data centre.

"well, I don't know, it just broke. Can you fix it?"

"yeah, but it's gonna cost you"

"you mean it's not warranty"

"no dude. You definitely broke it, but I'll look into it and make sure"

"thanks, eh. I don't know why this keeps happening to me"

"I know why. I'll call you when it's ready"

anyway, what I see is a crack that somehow initiated at the right angle where the lock and stop face meet. My guess is that that crack initiated long ago, probably when you hit something hard ie; chopped or batoned something, and that the prying you did was the straw that broke the camel's back. If the right angle was super sharp and wasn't chamfered prior to heat treatment, it might be more susceptible to developing a crack there through use, or might even develop a crack during heat treatment, which would grow over time through more use and corrosion.

if you get a replacement blade made, you might really enjoy 3V. If heat treated in a certain way, it retains more of its chromium and can be pretty close to stainless, and is tough as anyone could need in a knife that size. Maybe not the ideal choice for some things, but for what you do it would be great.

I know he's a problematic character, but I have a deep appreciation for Neil Blackwood's design work, and have always wanted one of those Ruckuses

One thing that comes to mind reading your thread- well, I deal with people's broken stuff all the time; mountain bikers mainly. In my business, JRA is a ubiquitous expression and draws a knowing nod from anyone in the know. I have heard, more times than I can recall, that phrase which the acronym applies to, used by folks who are bewildered that their bike suddenly broke.

"nothing happened! I can't believe my bike broke! I was just riding along!..."

"yeah, but like, what kind of things have you done with your bike since you've had it?"

cue rapid memory access- eyes flickering as each badly landed drop, cased jump or yard sale is accessed from the ole gray data centre.

"well, I don't know, it just broke. Can you fix it?"

"yeah, but it's gonna cost you"

"you mean it's not warranty"

"no dude. You definitely broke it, but I'll look into it and make sure"

"thanks, eh. I don't know why this keeps happening to me"

"I know why. I'll call you when it's ready"

anyway, what I see is a crack that somehow initiated at the right angle where the lock and stop face meet. My guess is that that crack initiated long ago, probably when you hit something hard ie; chopped or batoned something, and that the prying you did was the straw that broke the camel's back. If the right angle was super sharp and wasn't chamfered prior to heat treatment, it might be more susceptible to developing a crack there through use, or might even develop a crack during heat treatment, which would grow over time through more use and corrosion.

if you get a replacement blade made, you might really enjoy 3V. If heat treated in a certain way, it retains more of its chromium and can be pretty close to stainless, and is tough as anyone could need in a knife that size. Maybe not the ideal choice for some things, but for what you do it would be great.

I know he's a problematic character, but I have a deep appreciation for Neil Blackwood's design work, and have always wanted one of those Ruckuses

I feel your pain- been there myself many a time. So many damaged and broken knives- some real nice customs, too!

One thing that comes to mind reading your thread- well, I deal with people's broken stuff all the time; mountain bikers mainly. In my business, JRA is a ubiquitous expression and draws a knowing nod from anyone in the know. I have heard, more times than I can recall, that phrase which the acronym applies to, used by folks who are bewildered that their bike suddenly broke.

"nothing happened! I can't believe my bike broke! I was just riding along!..."

"yeah, but like, what kind of things have you done with your bike since you've had it?"

cue rapid memory access- eyes flickering as each badly landed drop, cased jump or yard sale is accessed from the ole gray data centre.

"well, I don't know, it just broke. Can you fix it?"

"yeah, but it's gonna cost you"

"you mean it's not warranty"

"no dude. You definitely broke it, but I'll look into it and make sure"

"thanks, eh. I don't know why this keeps happening to me"

"I know why. I'll call you when it's ready"

anyway, what I see is a crack that somehow initiated at the right angle where the lock and stop face meet. My guess is that that crack initiated long ago, probably when you hit something hard ie; chopped or batoned something, and that the prying you did was the straw that broke the camel's back. If the right angle was super sharp and wasn't chamfered prior to heat treatment, it might be more susceptible to developing a crack there through use, or might even develop a crack during heat treatment, which would grow over time through more use and corrosion.

if you get a replacement blade made, you might really enjoy 3V. If heat treated in a certain way, it retains more of its chromium and can be pretty close to stainless, and is tough as anyone could need in a knife that size. Maybe not the ideal choice for some things, but for what you do it would be great.

I know he's a problematic character, but I have a deep appreciation for Neil Blackwood's design work, and have always wanted one of those Ruckuses

Thank you. That explanation makes a lot of sense. The break did not follow the square notch for the blade stop like a stress riser, but was close. Under high magnification, that I cannot reproduce with my cell phone, I can see a number of fine cracks running perpendicular to the break, near the top of the break as it is shown in the photo. Years of hard use could have taken some defects past their yield point.

I think I need a new knife strategy. Rather than trying to get a large EDC to handle a wide range of hard tasks, I can keep a regular EDC for normal cutting purposes, and a larger blade to stick in my back pocket to pull out for chopping or other hard uses that come to bear when I'm outside.

I have an old Cold Steel Rajah I and Rajah II -- basically 6-inch Kukri choppers -- which are begging for that role.

scorpnsnake

Gold Member

- Joined

- Nov 8, 2023

- Messages

- 1,828

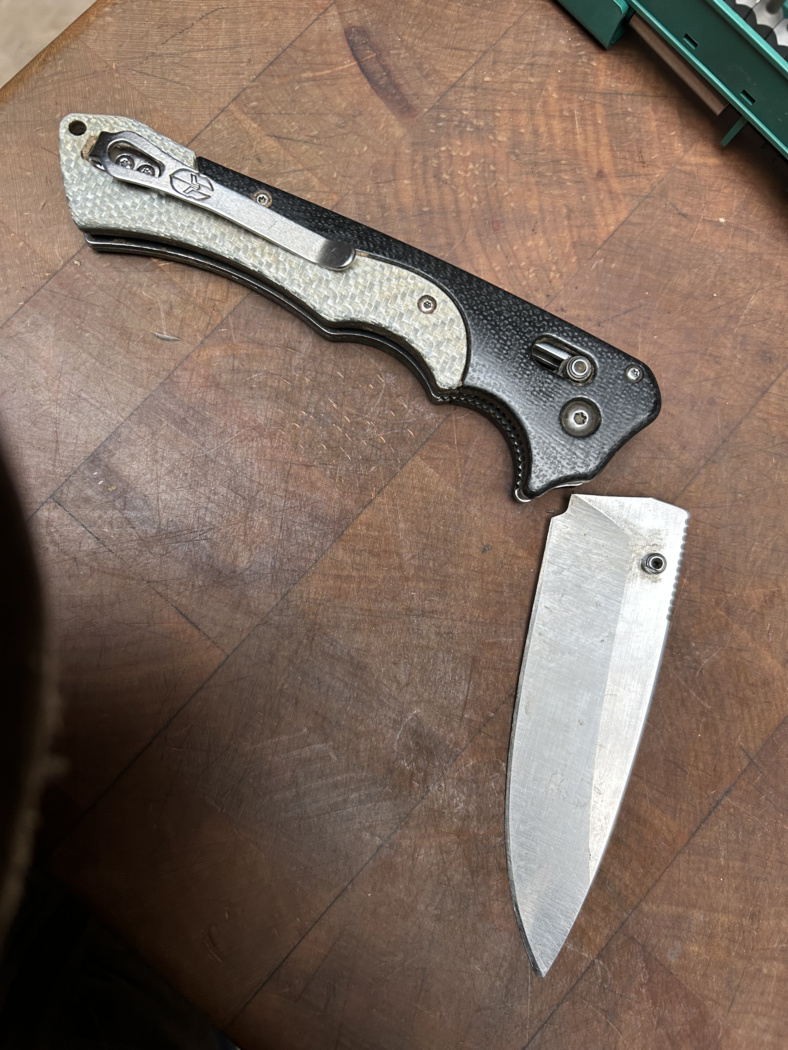

Here it in in better days:

This was a Rukus with a reblade in Vanax SuperClean steel, professionally heat treated by Peters to 60 Rc. It's a homesteading knife that I have used hard for years -- day after day. The edge was ground to 15 thousandths by Josh, and the edge angle is 15 dps. Cuts like a laser. Holds a great edge, never chips, never rolls, even with heavy chopping of branches that has destroyed other blade steels. It's big -- 4.25 inches of blade -- and has a long handle, which gives a lot of leverage. Love this knife. Best knife I have ever had -- by far.

So, yes, I was using it to pry. But gently. I was taking my mower back from annual servicing, and the handle is a bear to reconnect, mostly because of a lot of sharp edges that grab the fingers. So I used the Rukus to gently pry out a handle piece, being very conscious of not putting on too much pressure on the blade. Snap. Hardly any pressure. I don't get it.

The heat treat had to be spot on because this blade has been used so hard for so long with excellent performance.

The photos below are of the break. There are what look like inclusions and ripples and a chip off the chip and the grain has different kinds of coloring. I'm thinking the blade steel had some flaws. But I don't really know. I'm grieving.

Sorry to hear about your loss, she was a real beauty. Those hands are still plenty strong enough and working hard enough to break super steel. Respect..

Thank you. Actually, I've collected a large number of Rukus 610 and 615 models and various different scales. I've always loved this knife.Sorry to hear about your loss, she was a real beauty. Those hands are still plenty strong enough and working hard enough to break super steel. Respect..

So I did a bunch of bend to break tests and I was really surprised how easy most steels break. I would not expect Vanax to have a high bend to break strength from what I experienced.

Prying of any kind with high alloy steels is not the best idea.

Sorry about the break.

Prying of any kind with high alloy steels is not the best idea.

Sorry about the break.

So I did a bunch of bend to break tests and I was really surprised how easy most steels break. I would not expect Vanax to have a high bend to break strength from what I experienced.

Prying of any kind with high alloy steels is not the best idea.

Sorry about the break.

You are addressing the key. Fallkniven did a break test on some of its knives. The F1 (fairly similar in size to my Rukus) in VG 10 steel -- which is not as tough as Vanax -- broke at 90 Nm (J), which is about 66 ft-lbs. If I understand that result correctly -- a fairly iffy proposition -- the break came after putting the equivalent of 66 pounds of pressure on a foot long lever. I didn't put anything close to 66 pounds of pressure on my knife -- maybe 5-8 pounds -- and the lever length would have been three or four inches. I wasn't prying so much as trying to nudge a sharp corner into place that needed only firm finger pressure to accomplish.

I know prying is a bad idea, so I was being extra careful. I have used this knife hard, but always stopped well short of abuse.

It looks to me as though the break initiated at the top left, where a large chip was broken out and a number of fine cracks (not visible in my cell phone photo ) radiated out from. But I'm also concerned about the discoloring and the inclusions that show up as orange-ish spots.

SwissHeritageCo

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 8, 2021

- Messages

- 3,806

LOL. I'm a small, 77-year-old man with arthritis in my hands. Rooms don't empty when I walk in.

Thank you. That explanation makes a lot of sense. The break did not follow the square notch for the blade stop like a stress riser, but was close. Under high magnification, that I cannot reproduce with my cell phone, I can see a number of fine cracks running perpendicular to the break, near the top of the break as it is shown in the photo. Years of hard use could have taken some defects past their yield point.

I think I need a new knife strategy. Rather than trying to get a large EDC to handle a wide range of hard tasks, I can keep a regular EDC for normal cutting purposes, and a larger blade to stick in my back pocket to pull out for chopping or other hard uses that come to bear when I'm outside.

I have an old Cold Steel Rajah I and Rajah II -- basically 6-inch Kukri choppers -- which are begging for that role.

Yeah but the satisfaction isn't the same. The real fun in pocket knives is using them like you shouldn't.

I'd say your observations sound spot on. Terribly perceptive, hope I'm that sharp at 77

- Joined

- Dec 7, 2019

- Messages

- 3,644

Sorry about the break man. That sounds awful.

Absolutely ridiculous suggestion, but is there a chance the blade could still be “turned” into a fixed blade? Like the first 1/3rd of blade length can be covered with custom scales so you can still use about 2/3rds of knife? Holes would have to be drilled into this new makeshift tang for mounting scales. It would look something like a Mora Robust or Eldris.

If that sounds stupid or unviable, just ignore this post and I offer my apologies.

Absolutely ridiculous suggestion, but is there a chance the blade could still be “turned” into a fixed blade? Like the first 1/3rd of blade length can be covered with custom scales so you can still use about 2/3rds of knife? Holes would have to be drilled into this new makeshift tang for mounting scales. It would look something like a Mora Robust or Eldris.

If that sounds stupid or unviable, just ignore this post and I offer my apologies.

Sorry about the break man. That sounds awful.

Absolutely ridiculous suggestion, but is there a chance the blade could still be “turned” into a fixed blade? Like the first 1/3rd of blade length can be covered with custom scales so you can still use about 2/3rds of knife? Holes would have to be drilled into this new makeshift tang for mounting scales. It would look something like a Mora Robust or Eldris.

If that sounds stupid or unviable, just ignore this post and I offer my apologies.

Thanks of the suggestion.

That's possible, but what I liked about the Rukus was its size and its tank-like construction. Life is telling me to move on.

- Joined

- Jun 29, 1999

- Messages

- 10,053

That hurts. But a new knife will help heal your wound.

not2sharp

Platinum Member

- Joined

- Jun 29, 1999

- Messages

- 20,629

You, might have yet another great knife maker produce a replacement blade for you.Thanks of the suggestion.

That's possible, but what I liked about the Rukus was its size and its tank-like construction. Life is telling me to move on.

N2s

From me doing the bend to break test on quite a few steels I had on hand I was surprised that many of them did not necessarily follow impact toughness.You are addressing the key. Fallkniven did a break test on some of its knives. The F1 (fairly similar in size to my Rukus) in VG 10 steel -- which is not as tough as Vanax -- broke at 90 Nm (J), which is about 66 ft-lbs. If I understand that result correctly -- a fairly iffy proposition -- the break came after putting the equivalent of 66 pounds of pressure on a foot long lever. I didn't put anything close to 66 pounds of pressure on my knife -- maybe 5-8 pounds -- and the lever length would have been three or four inches. I wasn't prying so much as trying to nudge a sharp corner into place that needed only firm finger pressure to accomplish.

I know prying is a bad idea, so I was being extra careful. I have used this knife hard, but always stopped well short of abuse.

It looks to me as though the break initiated at the top left, where a large chip was broken out and a number of fine cracks (not visible in my cell phone photo ) radiated out from. But I'm also concerned about the discoloring and the inclusions that show up as orange-ish spots.

And for many of the steels I was surprised about how easy they broke by bending.