Yes that is along the same idea as a Sells handle. It has no bolt that interferes with hand placement on the back as a standard western handle does.

Here is another Sell with a short guard:

And an Atkins 52 that is similar but does not fit as many saws. A little different hole locations can interfere with the attachment of the #52

One disadvantage with the Sells type handles that I see frequently is loose handles. I don't think I have found one with a tight handle:

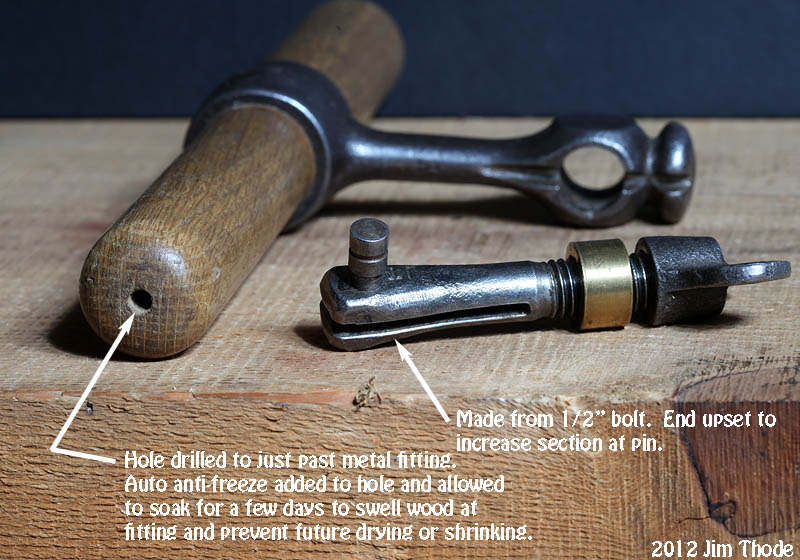

On all my users Sells handles I make a special effort to install the wood part of the handle so that they stay tight in all weather conditions. Without some care a handle can dry out and become loose in dry weather or storage conditions. My procedure is to only install the wood part when it is bone dry, in my case that means storing near the wood stove in the winter. Then working the handle so it is very tight in the metal fitting and I can just barely get it installed. Then my final step is to use some Swell Lock or straight auto antifreeze to swell the wood and prevent any drying or shrinking. I normally drill a hole down the center of the handle as well and dab some antifreeze around the outside. I have never had a handle loosen that I've did this process to.

Jim