Richard338

Gold Member

- Joined

- May 3, 2005

- Messages

- 7,493

Who cares

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Who cares

Who cares

Yet another interesting project Natlek - looking forward to seeing the finished knives

I don't. Tried out some ceramics a few years ago and didn't see enough improvement to justify the cost.Now I have million dollar question for you guys ..

Why in the name of God we use ceramic belts on simple carbon steel like 52100 , 1095 , 80CRV2 , 5160 ...etc WHY not AO belts ?????

It is 0.5mm deep now on edge , I want to end up with 0.2mm on edge before sharpening .So I need to change little angle , if I grind as it is I will pass spine . I will finish it this afternoon . So far I can t notice that paper is getting dull . This is first time I use AO paper on hardened steel for bevels .On my disks so far I used zirconia 40 grit and I was never happy .I try zirconia belt on grinder also , and they don t work for me .I can t explain why .They cut till they cut and then stop and start to heat steel too much . Zirconia grit should break to expose fresh tip as ceramic do but not in my case . What I think is good with AO is that grit wear /don t break/ and tip of grit round little and that s why they give much more nice finish ..I don't. Tried out some ceramics a few years ago and didn't see enough improvement to justify the cost.

How deep is the curved plunge are you getting on that knife? Looks like you have just scratched the surface. I was going through the paper on my disc sander way too fast to be able to finish even one side. Less paper and more heat due to the speed was killing the paper.

Now you know why it is called carbide *file* guideAnother win for Natlek

How do you finish the tang to ricasso/blade transition on hardened blades? I used the file guide, grinder and dremel with rotary tools but it's leaving too much marks on my nice carbide file guide.

ThanksNatlek this has been a great thread, very informative and awesome pictures. You've definitely got a knack for engineering a solution to a problem. I'm glad it all worked out for you!

Thanks, I have to attack that a m2 blade soon..Now you know why it is called carbide *file* guideI will take some pictures how I do that this days ......

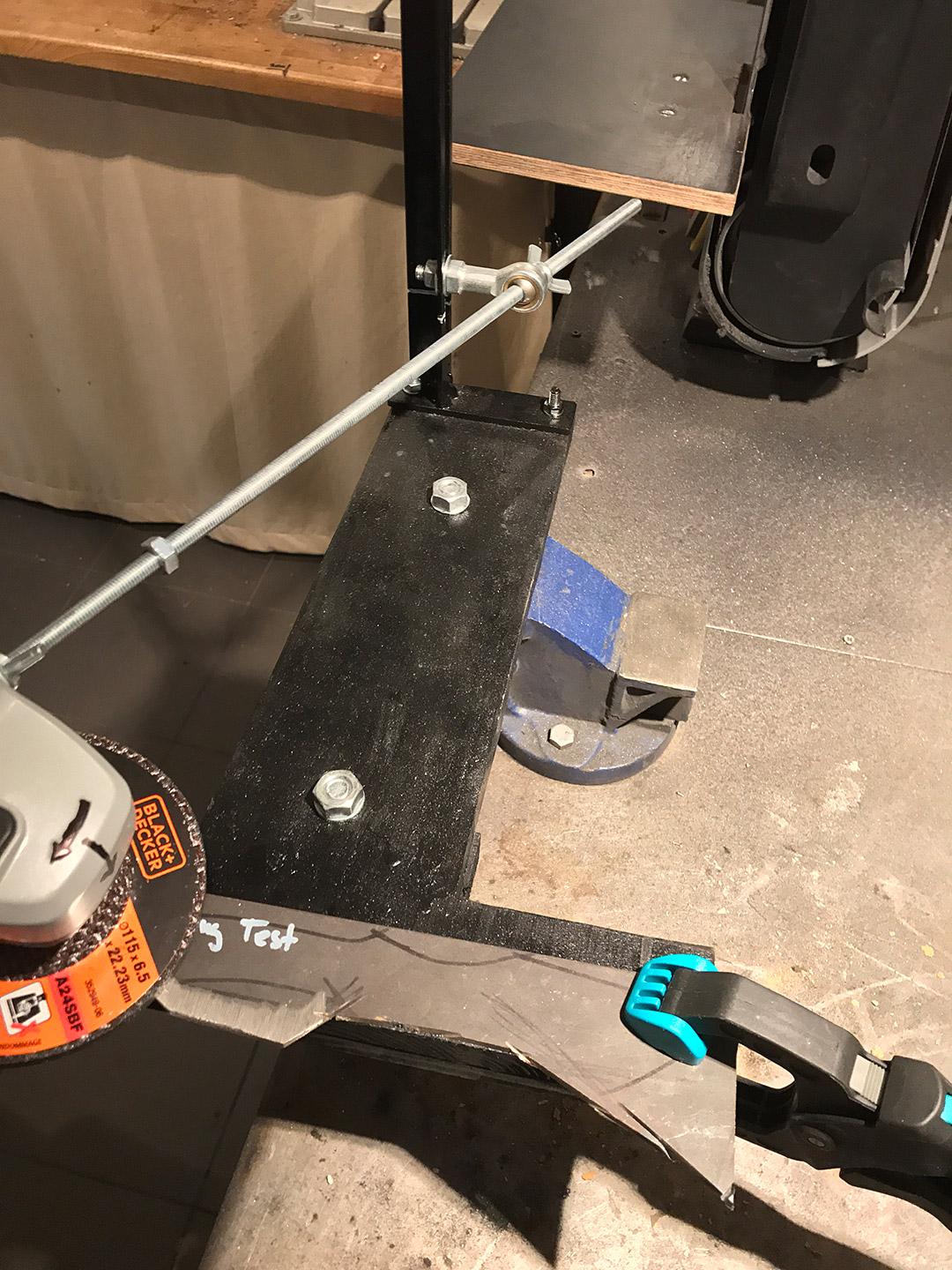

Hey Backyard, I made something like this with a simple eyehook for the rod to pass through. I see you are using something that has an insert that can rotate. What do you call that and where did you find it?I built something very much like this. Based on the file guide but made to hold angle grinder. Positioned at the right length and for the sweep of the blade it makes those plunge lines that you want

Uni ball bearingHey Backyard, I made something like this with a simple eyehook for the rod to pass through. I see you are using something that has an insert that can rotate. What do you call that and where did you find it?

They are traditionally known as Heim joints but also can be called rod end bearingsHey Backyard, I made something like this with a simple eyehook for the rod to pass through. I see you are using something that has an insert that can rotate. What do you call that and where did you find it?

Thanks guys, I think I found a couple that would work to update my jig.They are traditionally known as Heim joints but also can be called rod end bearings

McMaster carr has just about every size and shape you can think ofThanks guys, I think I found a couple that would work to update my jig.