the only part true about your statement is heat treatment is very importantUmm, D2 is D2… But more specifically to your question it depends on the heat treat. There’s no such thing as “Chinese D2”. It’s either the real thing or it’s not, and then the heat treat matters after that.

deep dive...

I've mentioned this before, and there are other threads that talk about it:

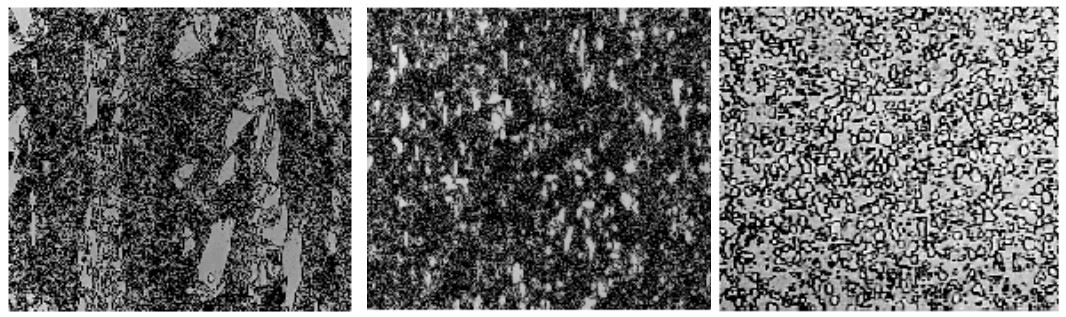

Typical mass produced d2 in the orient tends to actually be this 'equivalent' : cr12mo1v1 or even cr12mo1v

- notice the key difference, skimping out on vanadium - only 0.15-0.3% let's call it 0.25% to be generous

... which is still 4 times less than the spec of 1%

even the good quality bohler has a different version of d2 they call k110 - http://www.zknives.com/knives/steels/Bohler-Uddeholm/k110.shtml

the better oriental knife makers use k110 (I think they make it locally) - cleaner steel for sure & much closer to spec, but still can be as low as 0.7% vanadium

... here is a perfect bestech example: https://www.knifecenter.com/item/BT...one-drop-point-blade-milled-black-g10-handles

but the old gold standard is old school carpenter 610

I think Dozier used this one

d2 is old stuff, back when wide variations were allowed because they didn't really understand how very slight differences really impacted steel

if you want the authoritative write up about d2 - thank Dr.

All About D2 Steel - Development, Use in Knives, and Properties - Knife Steel Nerds

Thanks to Robert Erickson, knifeandgear_swiss, Dale Bushness, and Paul Hart for becoming Knife Steel Nerds Patreon supporters! Update 10/22/2020: I now have an article with how to heat treat D2, PSF27, and CPM-D2 and it also includes toughness testing of each steel and edge retention testing of...

Last edited: