- Joined

- Jul 30, 2006

- Messages

- 43,270

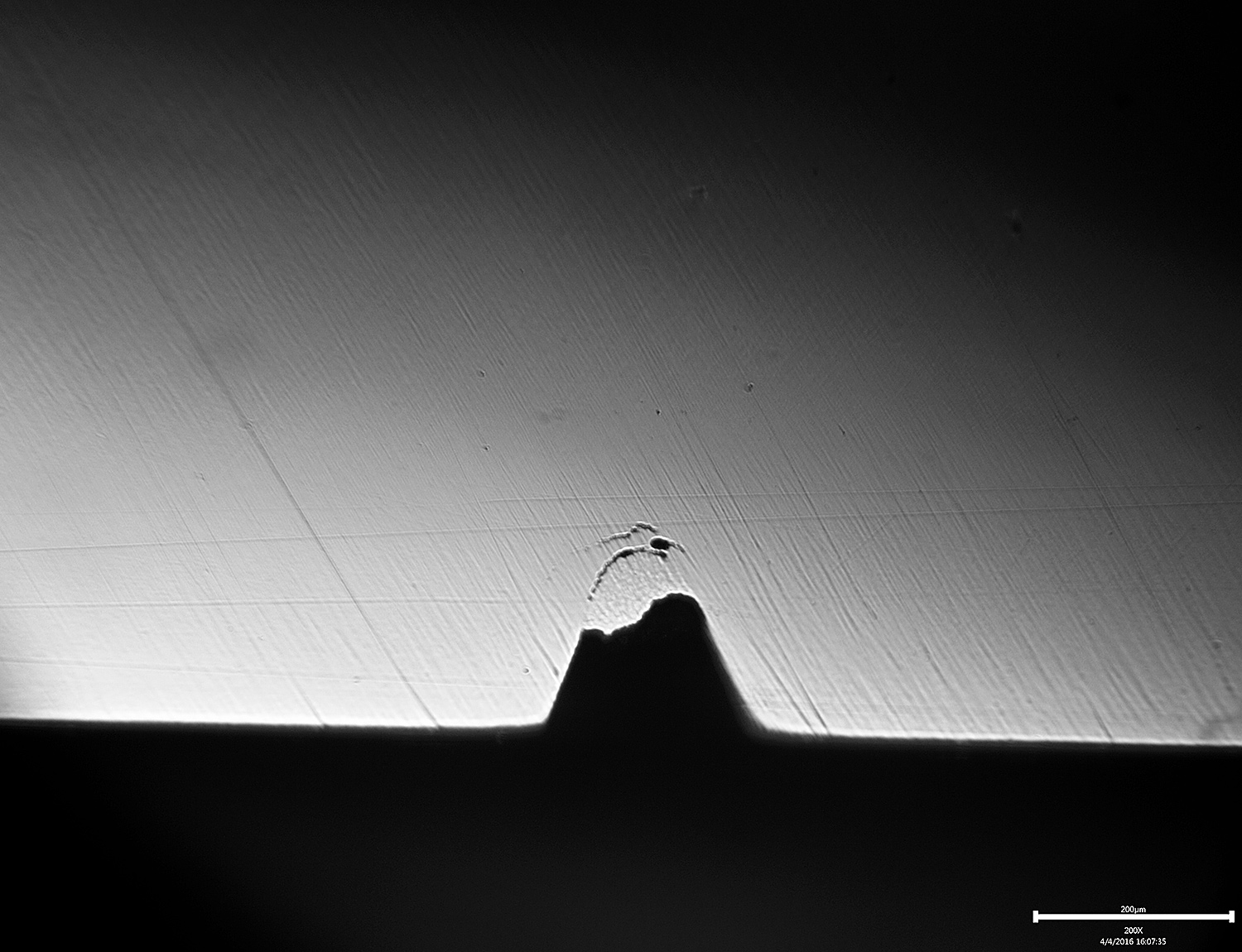

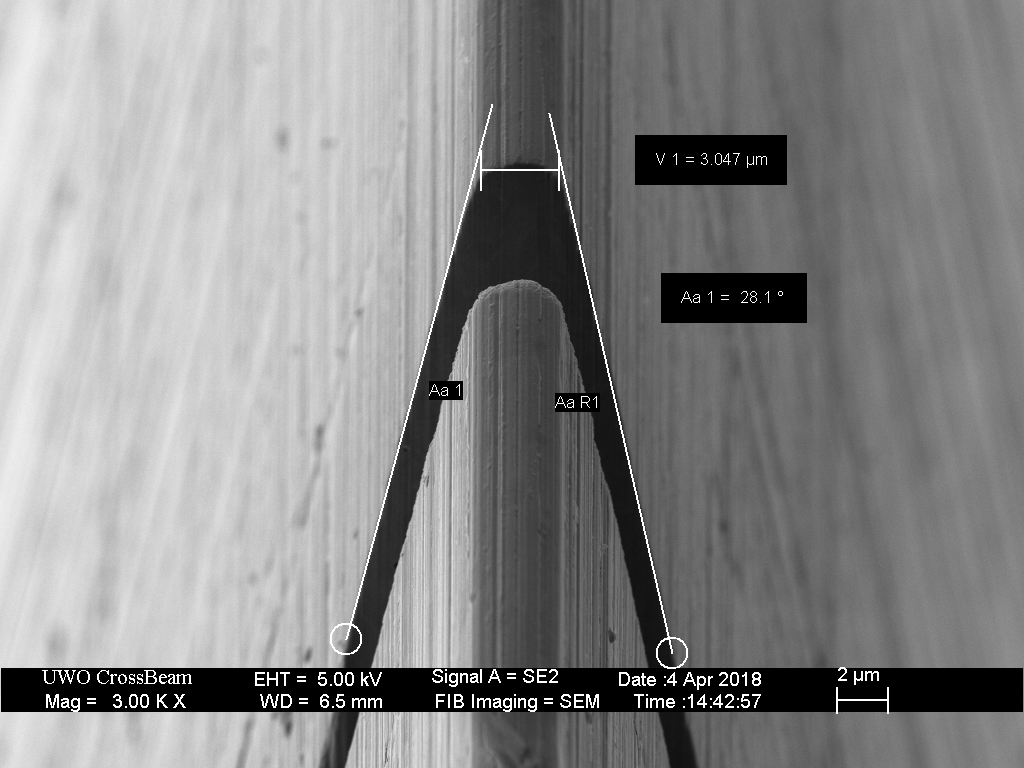

We really need Bear to explain what he means. I did watch his video. He says the edge fatigue occurs with stones softer than diamonds and CBN. I think the idea is that softer stones are unable to cut the large, hard carbides in the high-carbide steels; so they plow up the softer steel matrix, leaving the carbides standing proud on the edge. In that condition, they can be knocked out of the apex, leaving a fracture point that damages the edge and reduces cutting performance.

With diamonds, the carbides are sharpened along with the matrix, so you don't get that carbide pullout.

I think this effect would be most likely in steels like 440C, D2 and ATS 34, where the carbides are large and often clumped together.

DeadBoxHero and I have been having a discussion offline.

What he describes is a crappy, brittle, edge in high hardness, high carbide volume alloys when they are sharpened with aluminum oxide stones.

My opinion is that this is due more to what you are describing than to actual "fatigue". The abrasion media needs to be harder than what you are trying to abrade; else you end up with shattered carbide chunks and carbides torn out of the steel matrix. Such tears would be expected to weaken the steel.